Q5: Given the past fast growth, I am skeptical how large the market is & how much they can grow.

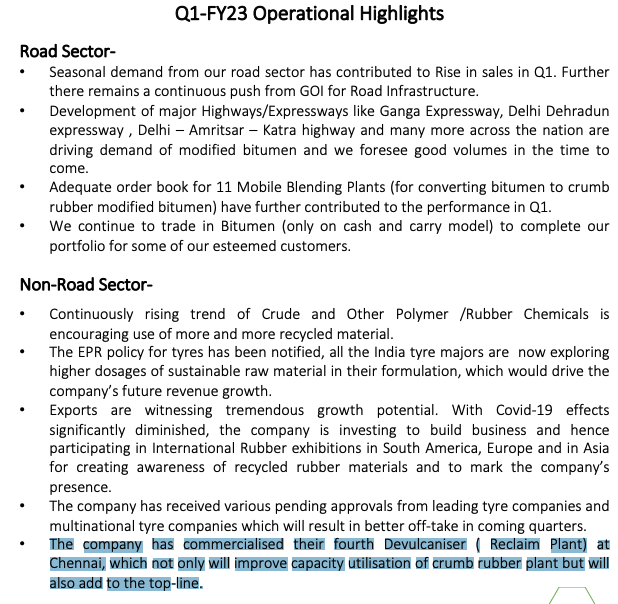

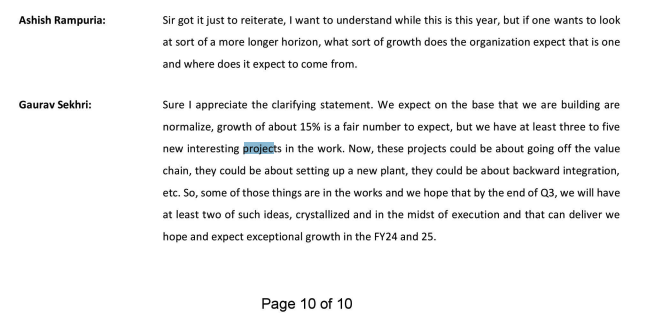

A: Let us analyse the Road & Non-Road segments separately.

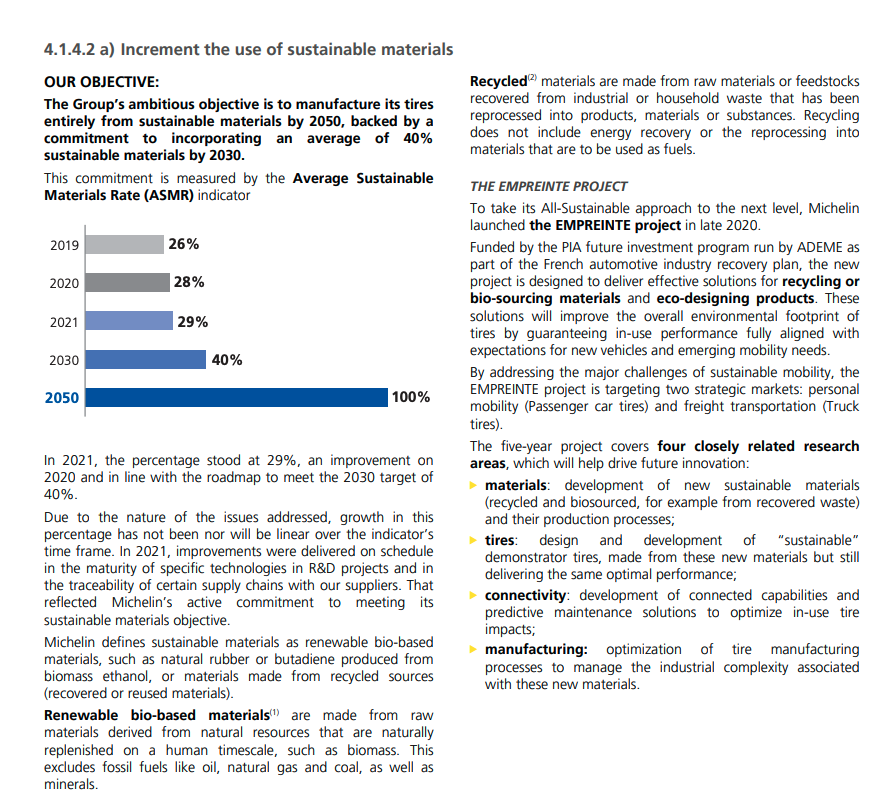

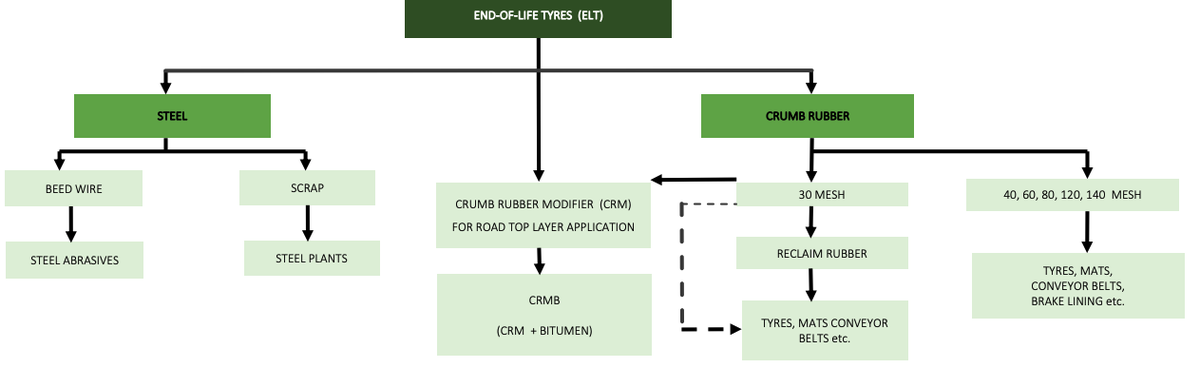

India uses 7 million ton of Bitumen annually. This can use 12-14% blending. So the TAM here is around 9 lakh tons.

A: Let us analyse the Road & Non-Road segments separately.

India uses 7 million ton of Bitumen annually. This can use 12-14% blending. So the TAM here is around 9 lakh tons.

Current demand & supply is around 2 lakh ton. The potential to grow is around 5x (of course this needs creating awareness, creating the market, educating the infra & construction cos on the benefits of blending CRM with bitumen).

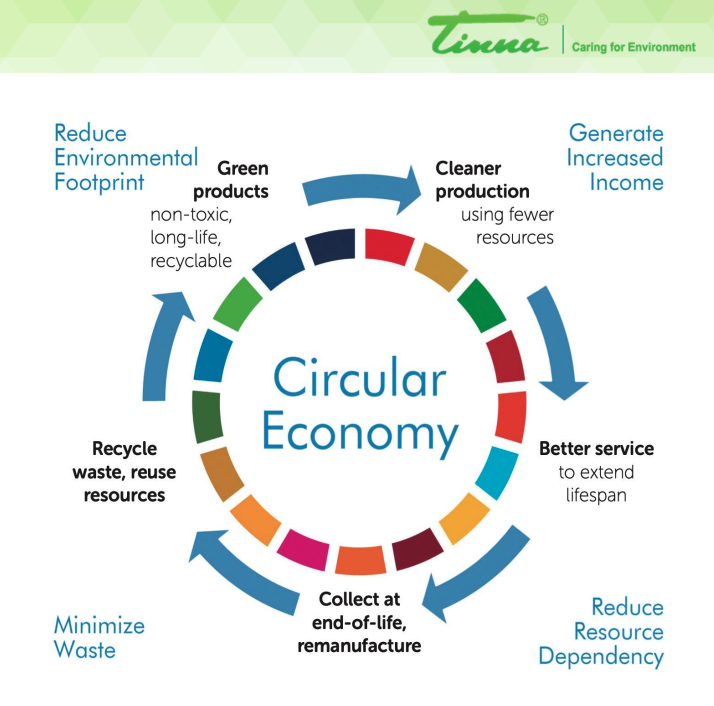

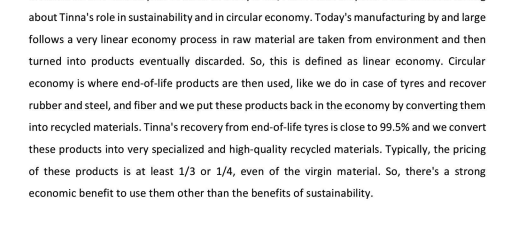

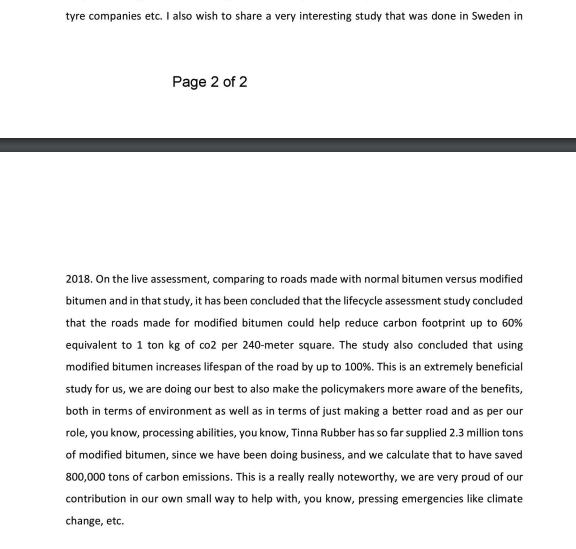

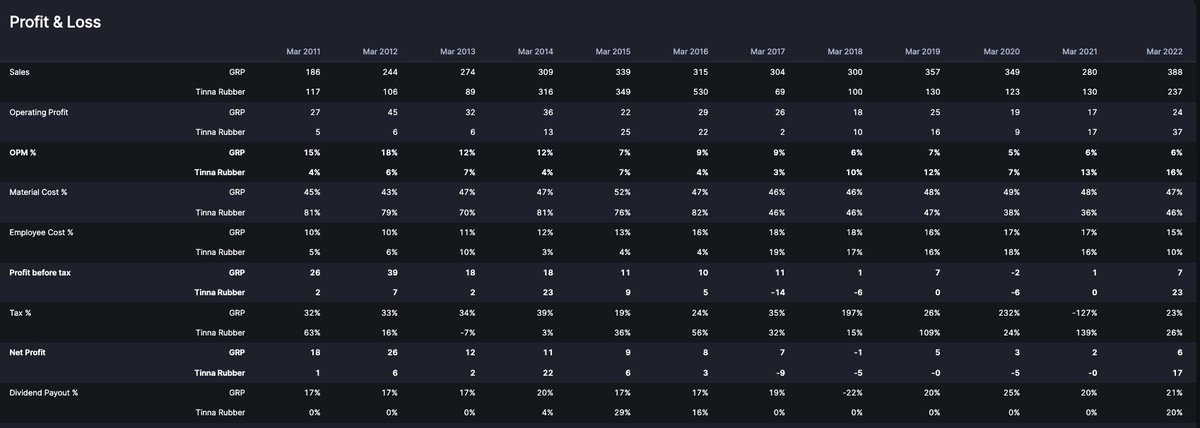

Src: youtube.com

Src: youtube.com

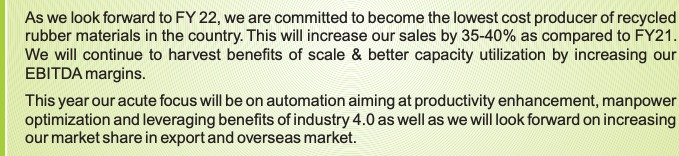

Please be prepared for a mini-diversion into why Tinna might have succeeded where GRP has not.

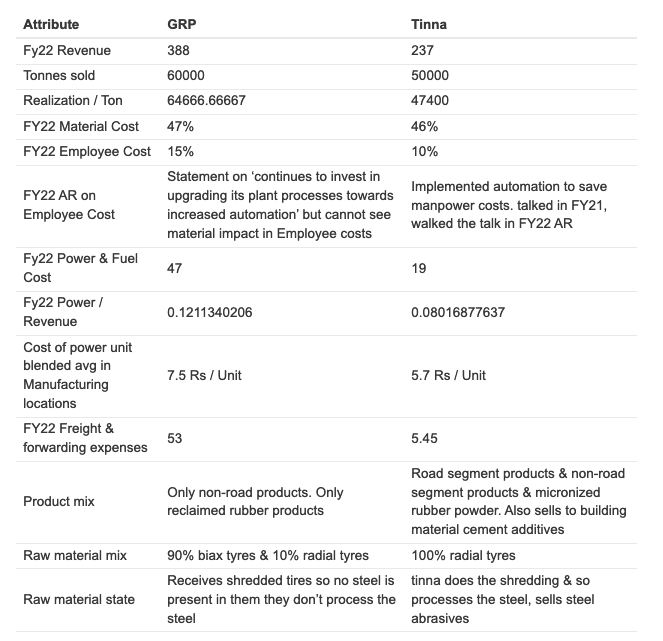

1. Tinna is more forward integrated: Please see from 56:10 (youtu.be). He tells diff between grp & tinna.

1. Tinna is more forward integrated: Please see from 56:10 (youtu.be). He tells diff between grp & tinna.

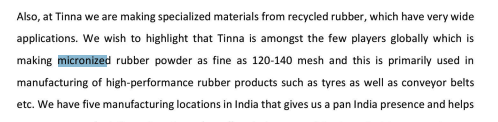

Expectedly CRM would not bond or dissolve easily with bitumen or virgin rubber of the tyre (he explains that here: youtu.be).

This is why MRP is a superior product (easier & more structural integration with virgin rubber or bitumen).

This is why MRP is a superior product (easier & more structural integration with virgin rubber or bitumen).

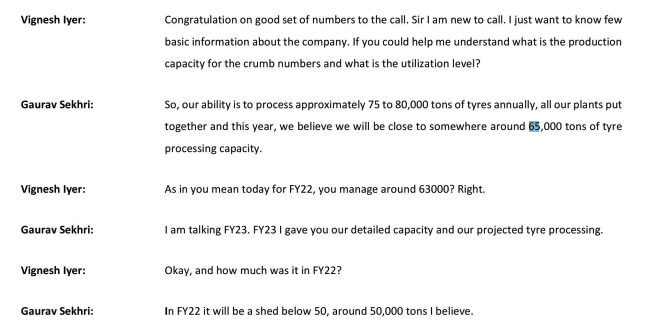

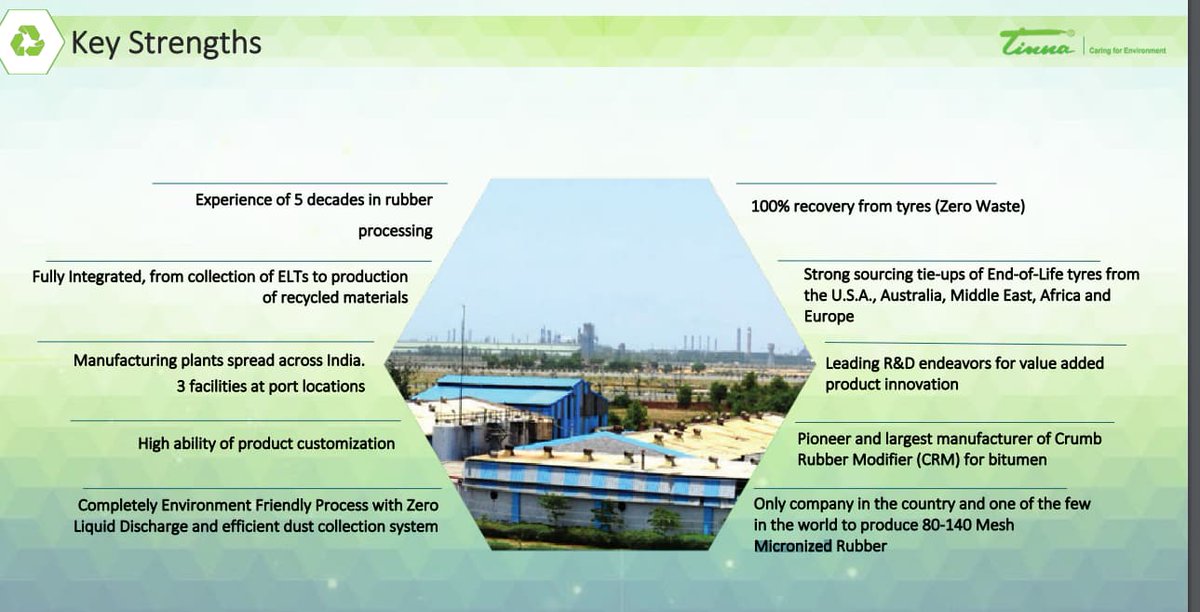

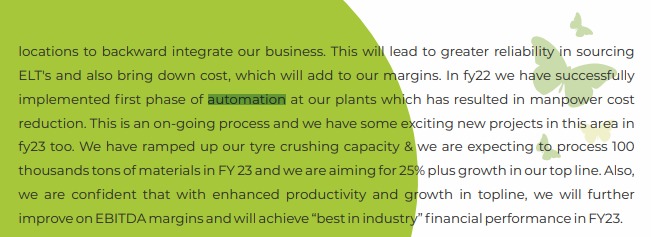

Tinna did 10000 ton of MRP in FY22 (source: youtu.be)

That is roughly 20% of their volume output (must be higher % of value output).

That is roughly 20% of their volume output (must be higher % of value output).

Could be part of the reason why GRP has not been able to grow its topline is it possible that MRP usage increase is causal or correlated with CRM usage plateauing?

…the steel wire present in the tyre & sells it as well.

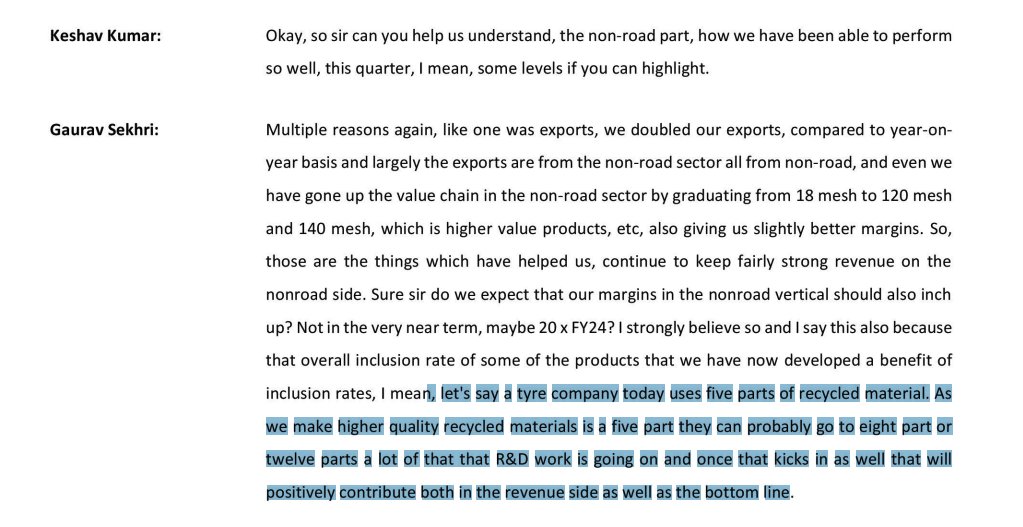

Tinna also says in their concalls that radial tyres are higher quality & enable them to make higher quality products.

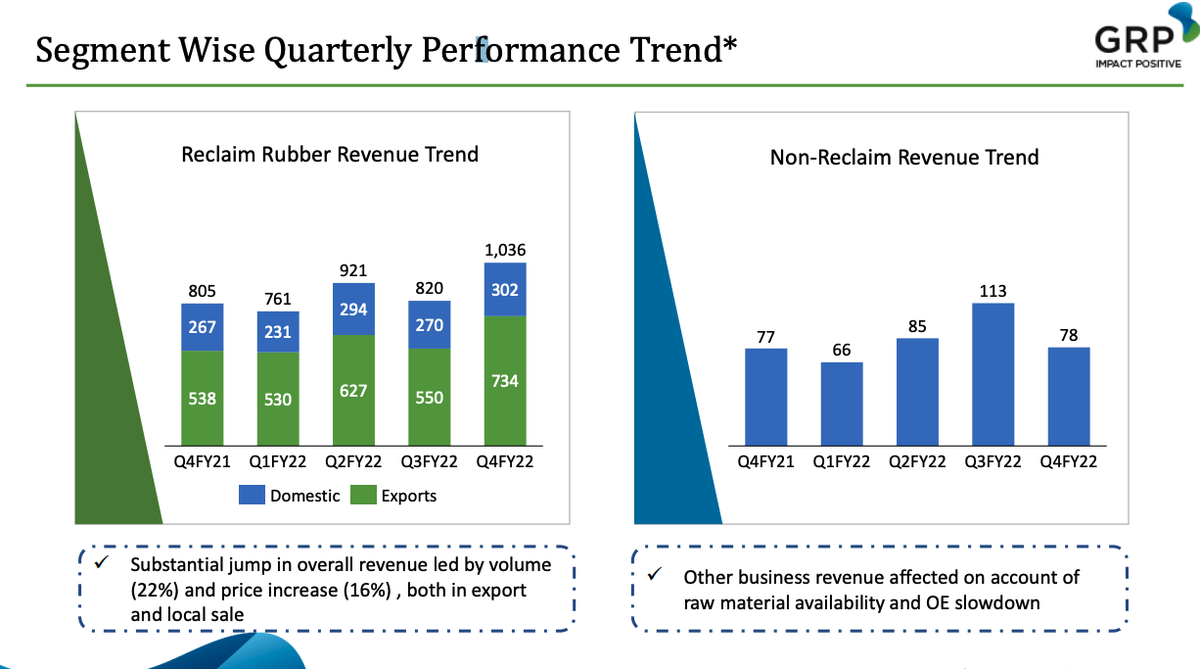

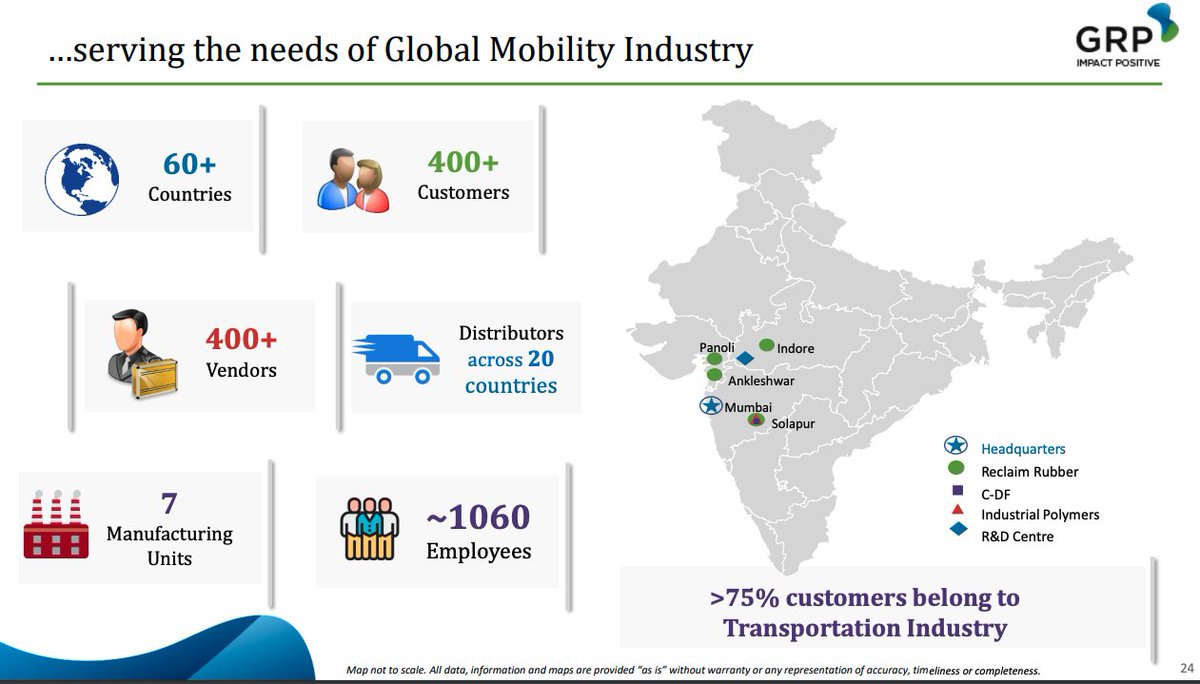

5. GRP has higher % of exports (40%). But, On EBITDA margins, GRP freight costs is massive at 50cr, so we have to validate whether export is really high margin for them (ex of the freight costs),

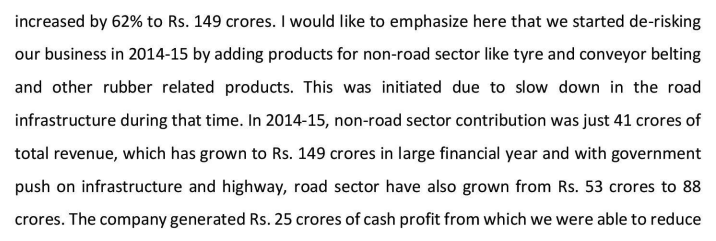

Tinna in comparison being largely domestic focussed has negligible freight costs (Tinna gets 5% from exports, GRP gets 40% from exports)

6. Material cost: wise both are neck & neck, around 45% material costs in FY22 for both of them.

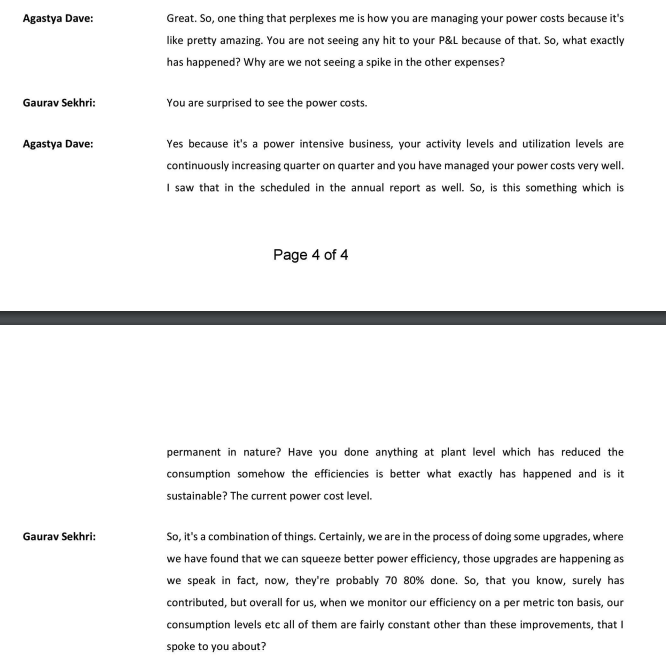

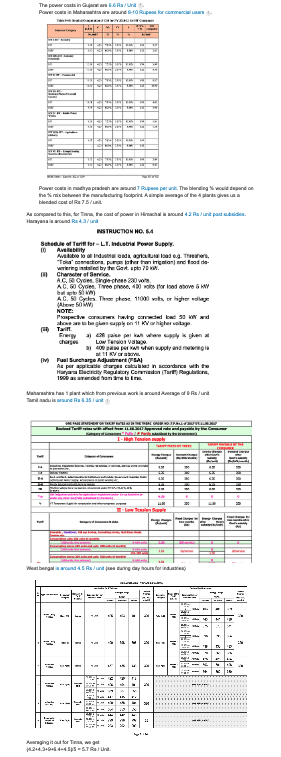

This is a little bit vague & i would love to ask Tinna management what these exact upgrades are which enable higher power efficiencies.

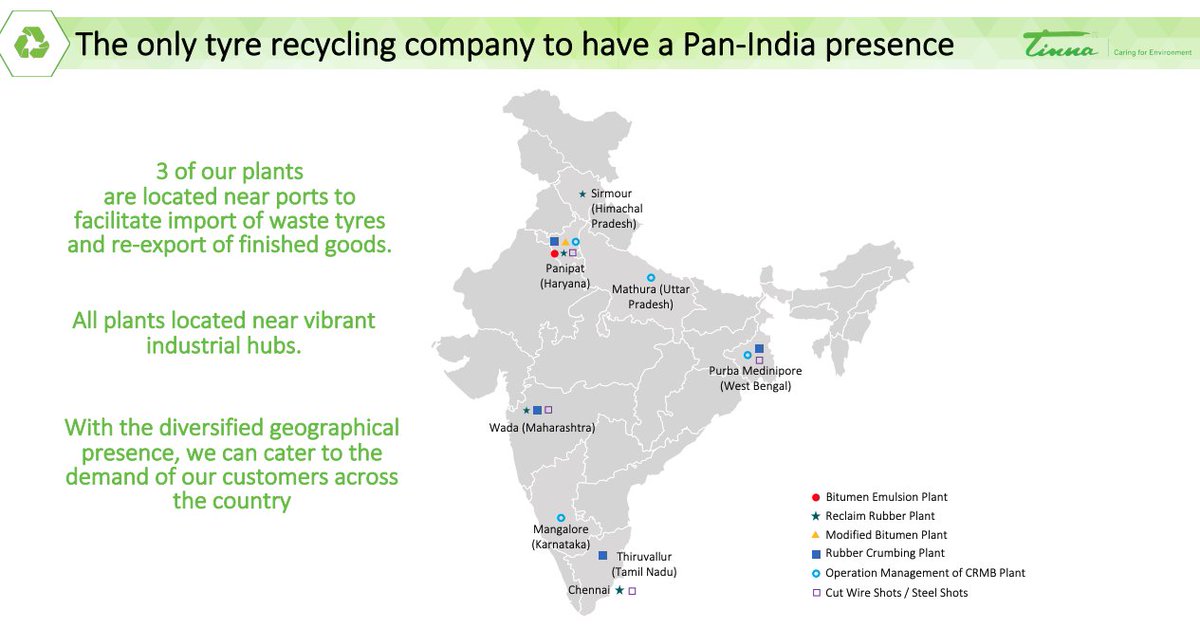

iii. (competitive advantages): Tinna is largest & only scaled producer of micronized rubber powder in india. 85-90% market share. Not the largest one, the only one. As @Amit_Jeswani1 sir says. Also one of largest tyre recyclers in india.

(next only to GRP but i expect tinna to overtake GRP in next 2 years).

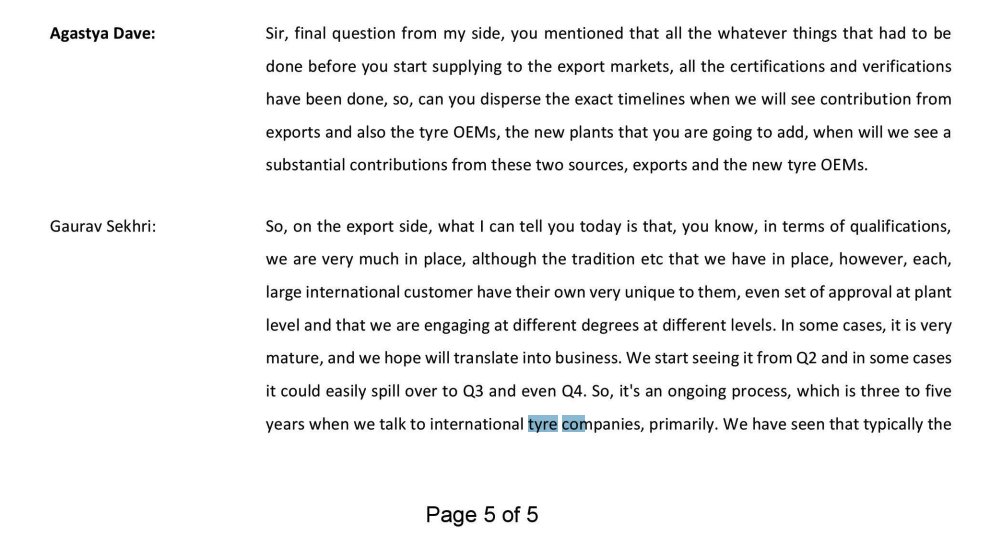

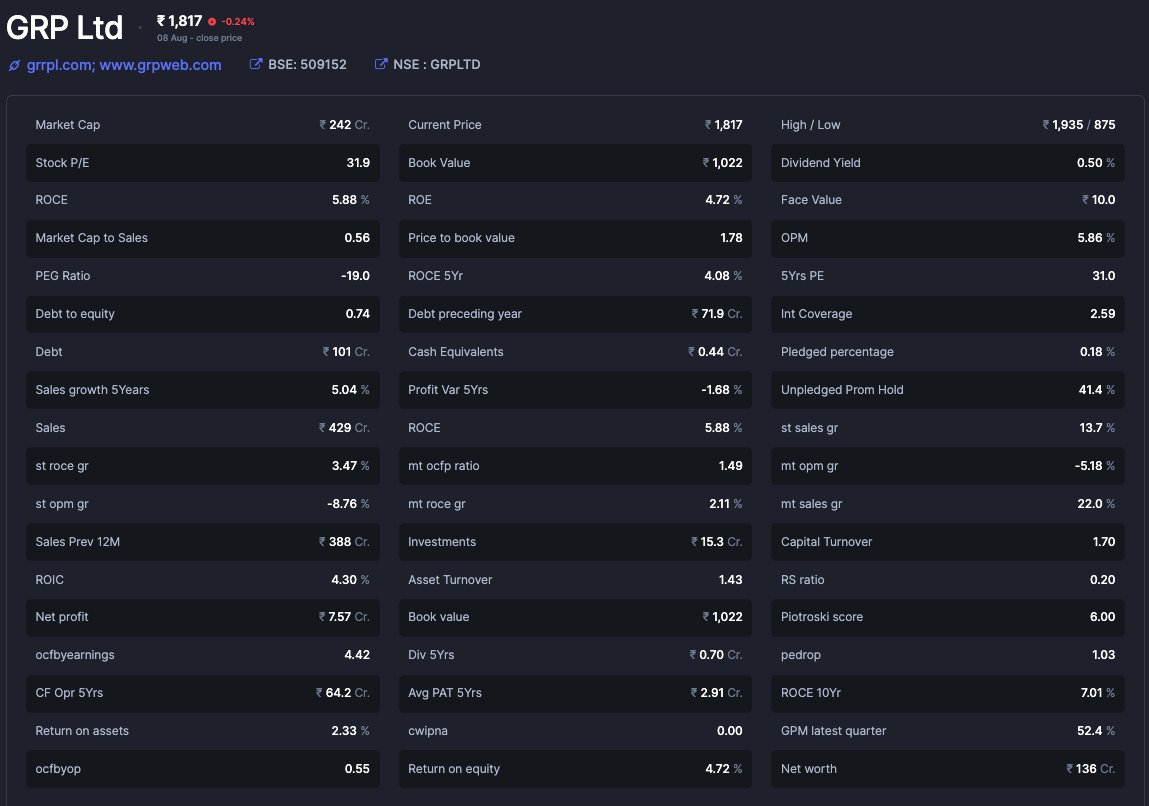

Q10: Seems like the kind of co you'd want to own. What is the valuation you are paying?

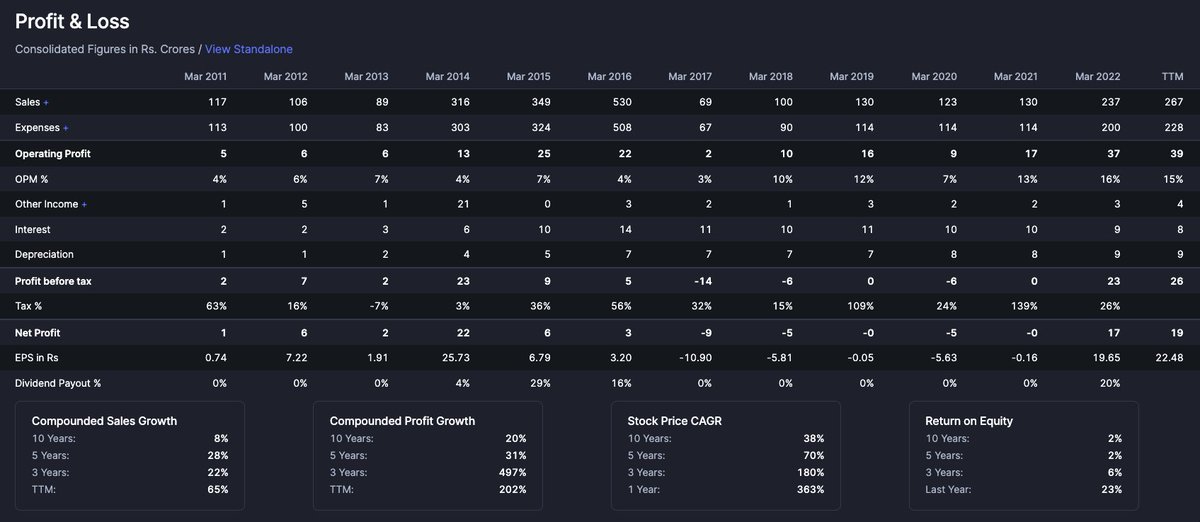

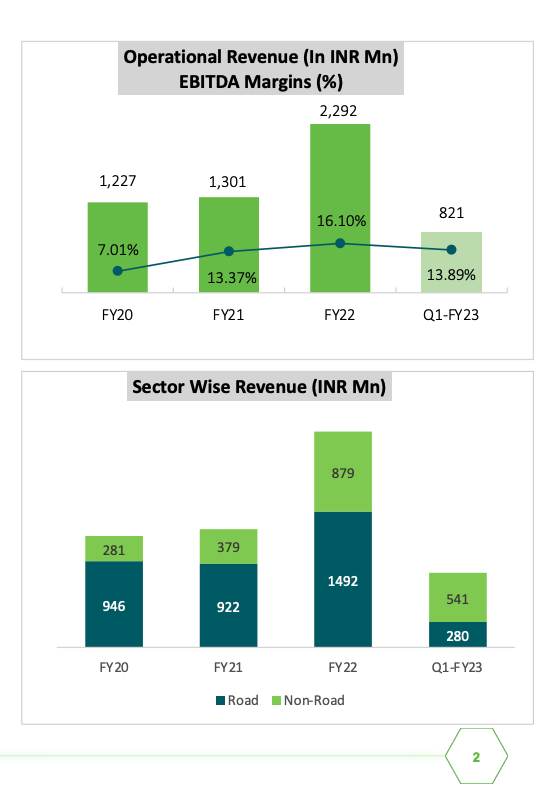

A: when i started buying tracking quantities last week, it was around 17x TTM earnings. Co has guided to do similar to Q1 for rest of FY23. At that point i was looking at a FY23 P/E of 13.

A: when i started buying tracking quantities last week, it was around 17x TTM earnings. Co has guided to do similar to Q1 for rest of FY23. At that point i was looking at a FY23 P/E of 13.

Since then, price has gone up 25% so P/E have also inflated to TTM P/E of 21 & FY23 P/E of 16.

Given the competitive advantages, growth (20-25%), opportunity size (at least 10x TAM imo), competitive positioning (largest player in most imp components), I think it is still a bit undervalued though it was too cheap last week.

Q11: Given the great ESG positive nature of industry what is government doing here?

A: Enter, EPR: Extended producer responsibility.

thepolicytimes.com

India actually generates 15-18 lakh ton!!!

A: Enter, EPR: Extended producer responsibility.

thepolicytimes.com

India actually generates 15-18 lakh ton!!!

Q11: Gotcha. What are the gotcha? what are the risks?

A: i. However much we might harp on ESG, companies have a profit motive. Without doubt the recent increase in rubber prices has caused tailwinds for tinna (reclaimed rubber would be cheaper).

A: i. However much we might harp on ESG, companies have a profit motive. Without doubt the recent increase in rubber prices has caused tailwinds for tinna (reclaimed rubber would be cheaper).

So, rubber prices can act as a headwind as well.

ii. If GRP gets their act together & becomes an efficient competitor then tinna could be forced to grow slowly or drop margins. Need to track GRP closely.

iii. Are the margin gains sustainable?

ii. If GRP gets their act together & becomes an efficient competitor then tinna could be forced to grow slowly or drop margins. Need to track GRP closely.

iii. Are the margin gains sustainable?

Will they revert to pre-covid levels? Product mix is better now so they shouldnt but one cannot be sure.

iv. Any delay in notification of EPR will adversely impact tinna's growth rates.

iv. Any delay in notification of EPR will adversely impact tinna's growth rates.

If you find the thread useful, considering following @sahil_vi for similar threads in the future. Please consider retweeting the 1st tweet too. It helps educate more investors.

A thread of all my long analysis threads:

A thread of all my long analysis threads:

Finally, a disclaimer: I am invested & biased. Do your own due diligence before taking any investment decision. I am not a sebi registered advisor. This is not a buy or sell reco. I am free to update my views in real time as facts change without updating anyone.

If i found a better co, id sell tinna tomorrow.

<End of thread, Enjoy your day>

<End of thread, Enjoy your day>

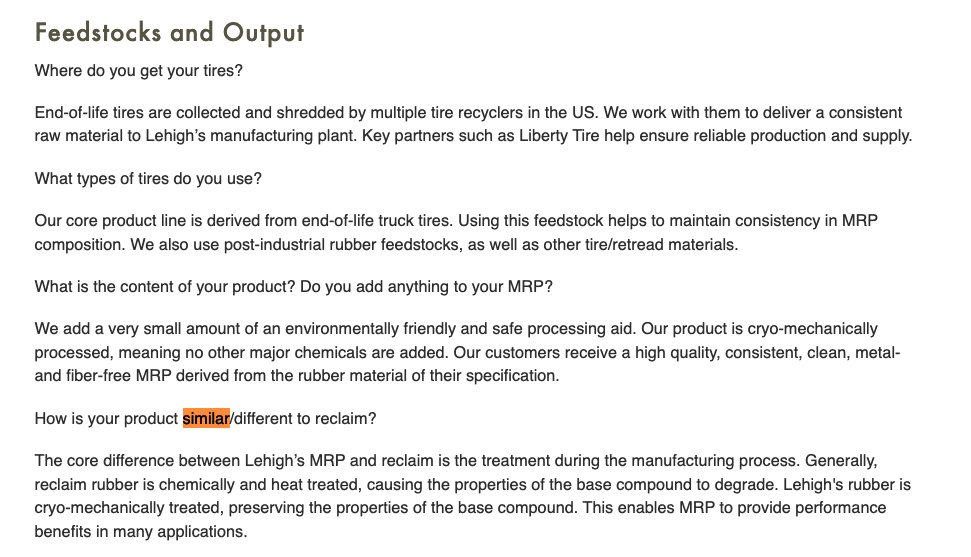

Some interesting differences b/w reclaim rubber & MRP:

lehightechnologies.com

src: vp: forum.valuepickr.com

lehightechnologies.com

src: vp: forum.valuepickr.com

Loading suggestions...