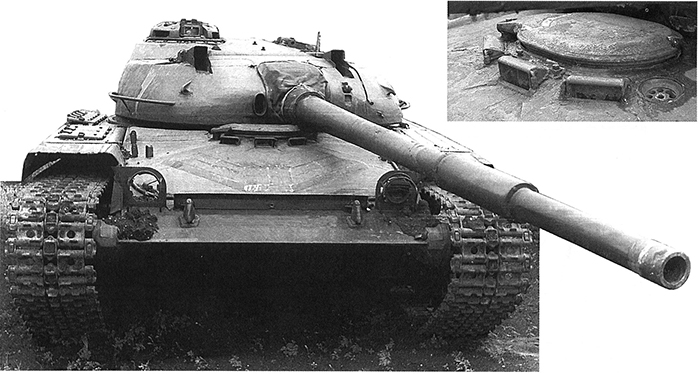

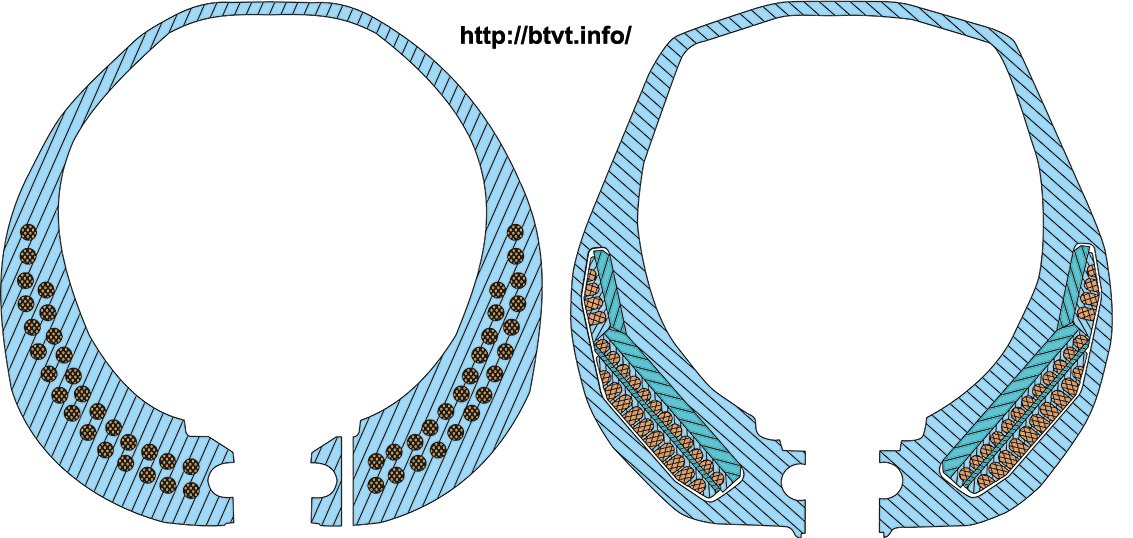

(3/16) The development of the T-64's turret was a complicated affair. The best history in English on it is @AndreiBtvt's article on Warspot, which was translated into English by @Tank_Archives.

tankarchives.ca

tankarchives.ca

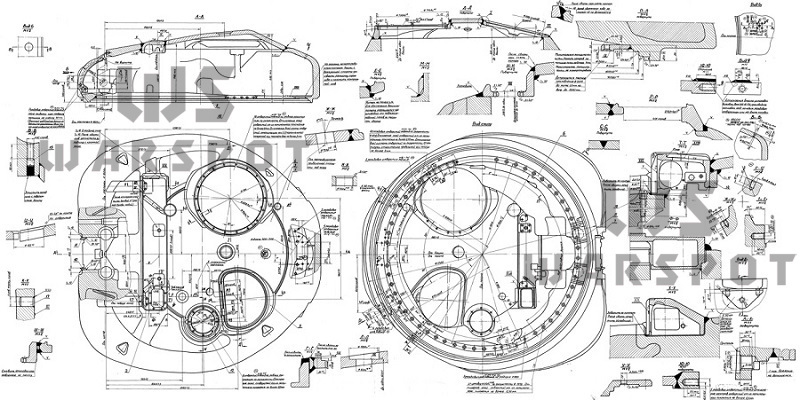

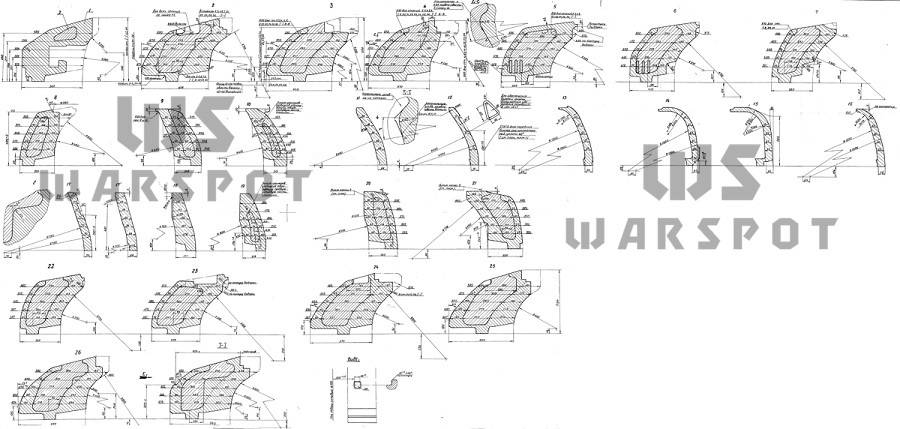

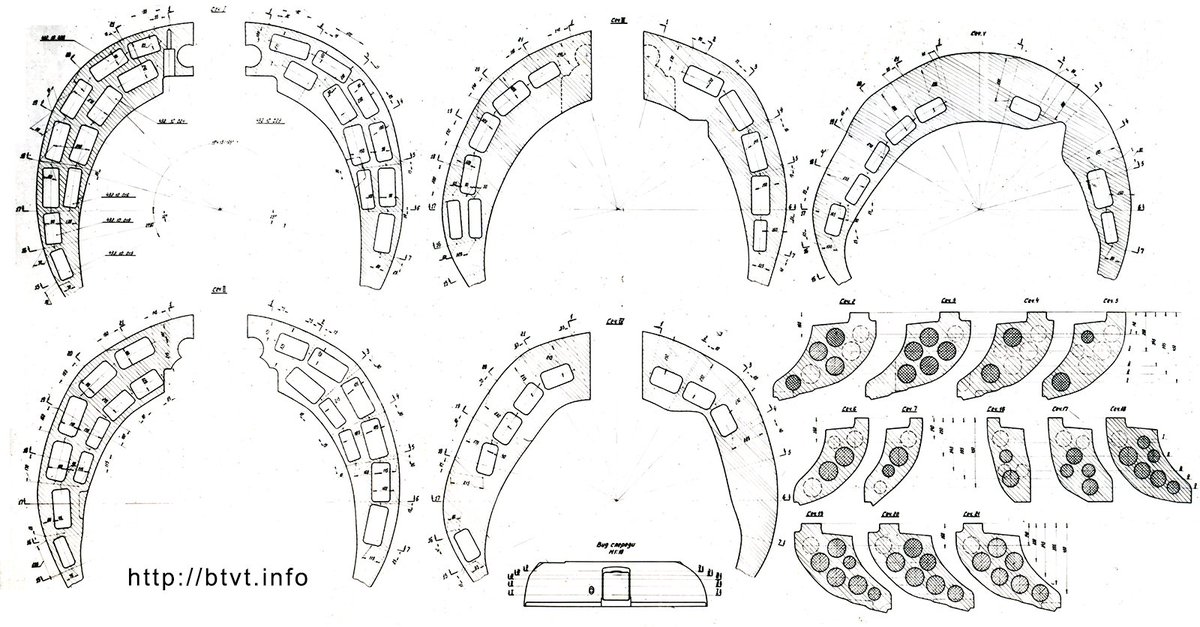

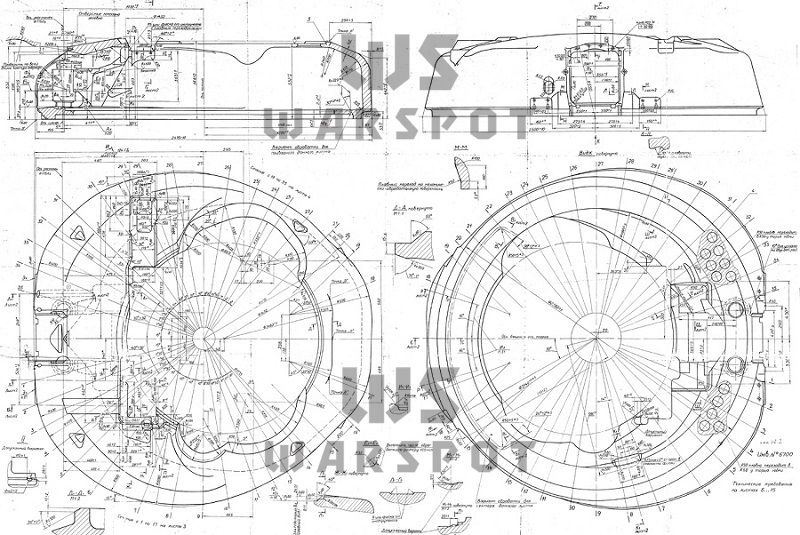

(7/16) Initially, high-hardness steel inserts were used, with a backing plate welded to the cast turret armour (this is the version present in War Thunder's T-64A)...

btvt.info

btvt.info

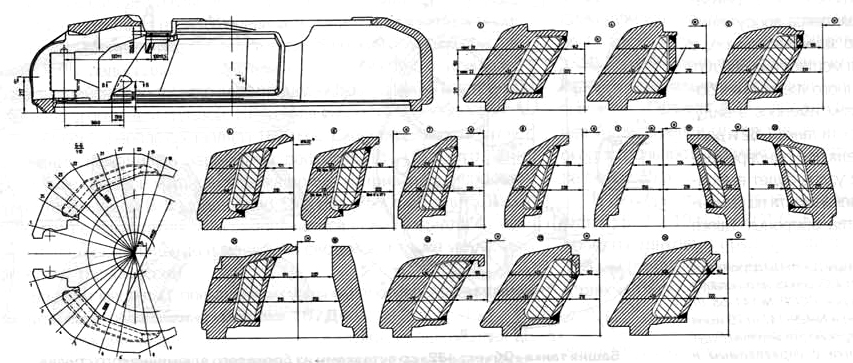

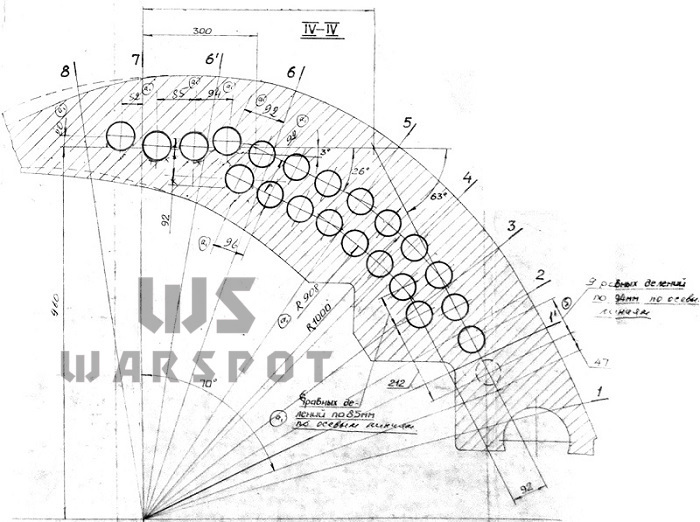

(10/16) 'Ultrafarfor' (ультрафарфор, 'ultra-porcelain') made from a mixture of alumina, clay, and barium carbonate. The process results in an ultra-hard mullite-corundum composite ceramic, which is why the KVP-98 balls are often called 'corundum balls'.

mash-xxl.info

mash-xxl.info

(14/16) And if you want to know what a riser is, here you go:

en.wikipedia.org

en.wikipedia.org

(15/16) Of course, they were never fully able to resolve some of the quality control issues casting molten steel onto the ceramic balls. It was also pretty much impossible to fix a turret with these balls, since you can't really just cut them open and put in new balls.

Loading suggestions...