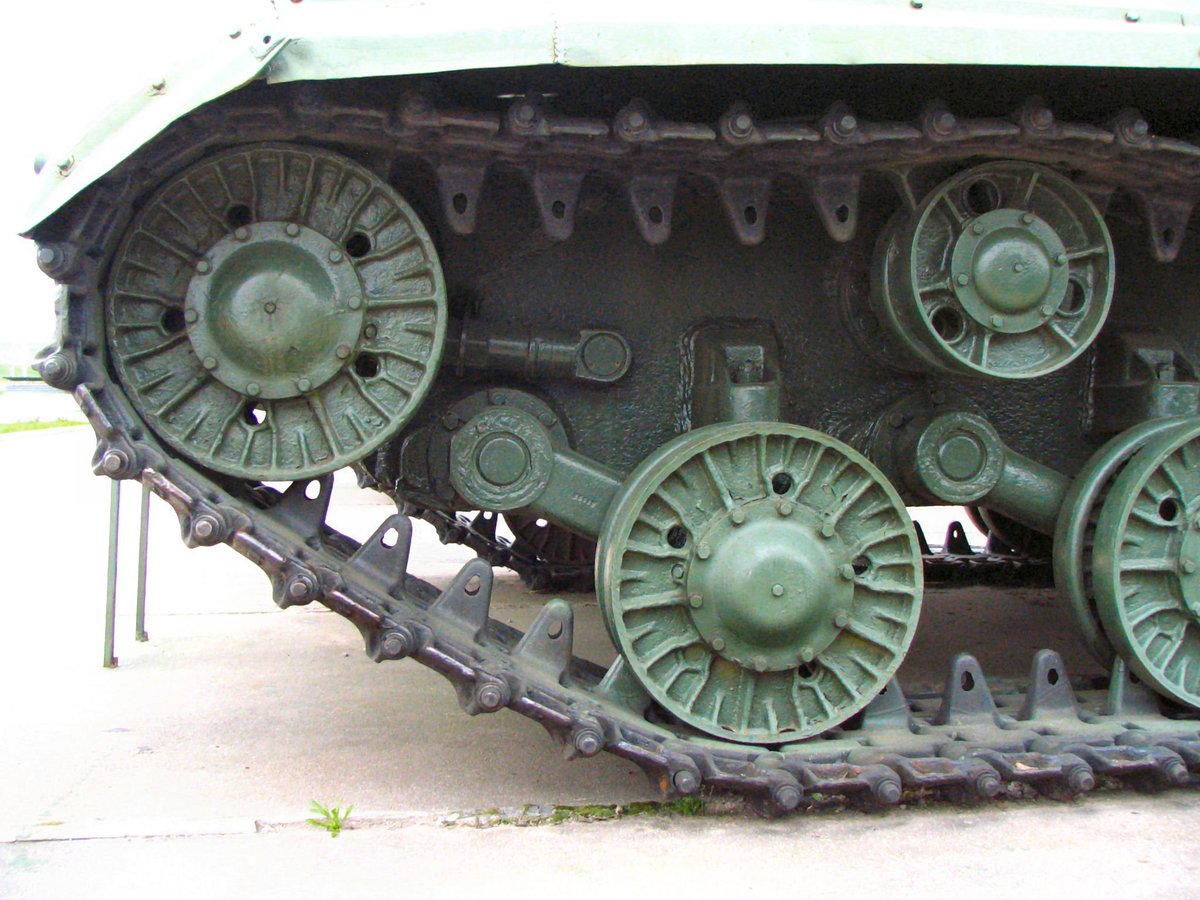

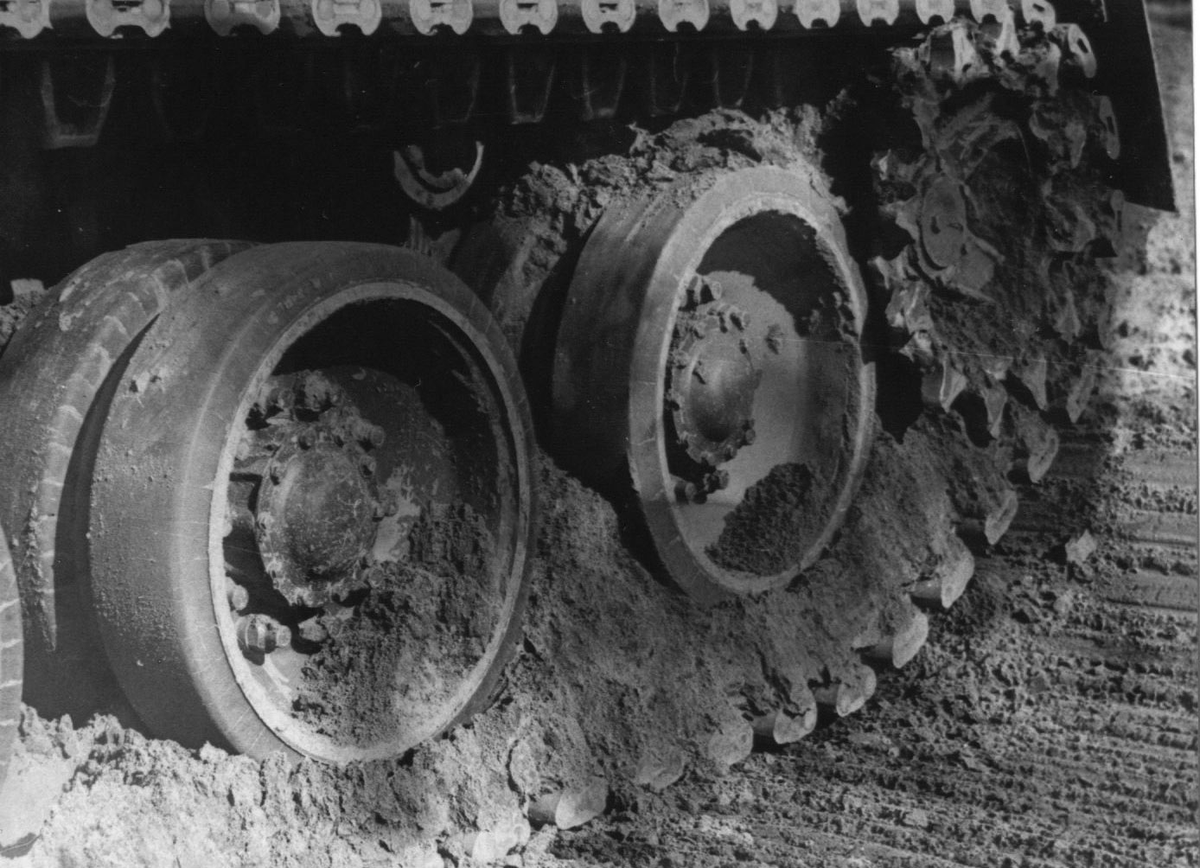

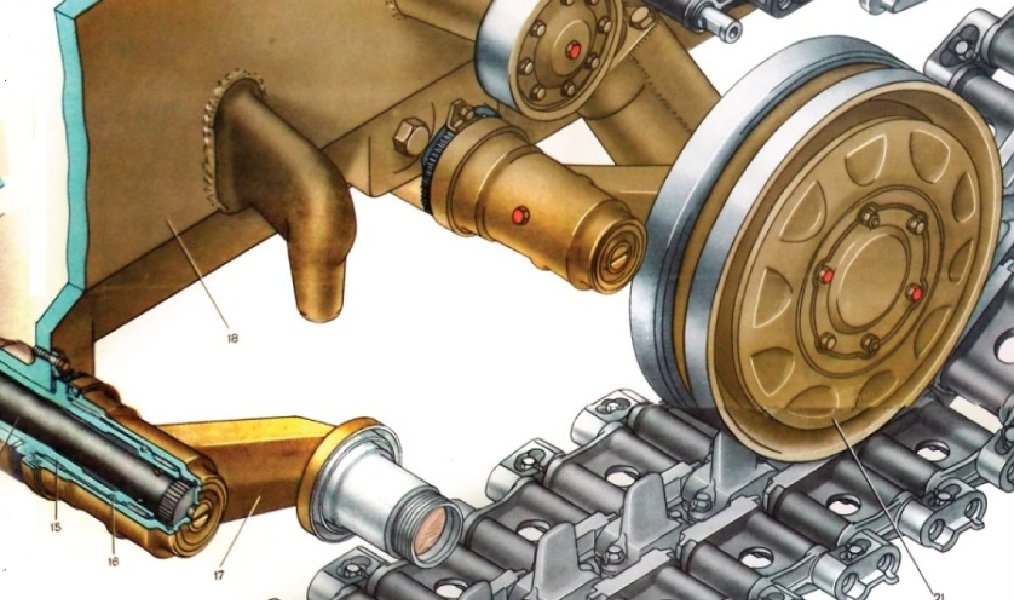

(7/17) In general, it is more difficult for this to occur on a T-64 because of the road wheel design and 'self-cleaning' holes of the tracks.

btvt-info.translate.goog

btvt-info.translate.goog

(11/17) I mentioned previously that these wheels were also used because of the napalm protection requirement. Because the rubber is placed internally, it doesn't get burned when subjected to napalm.

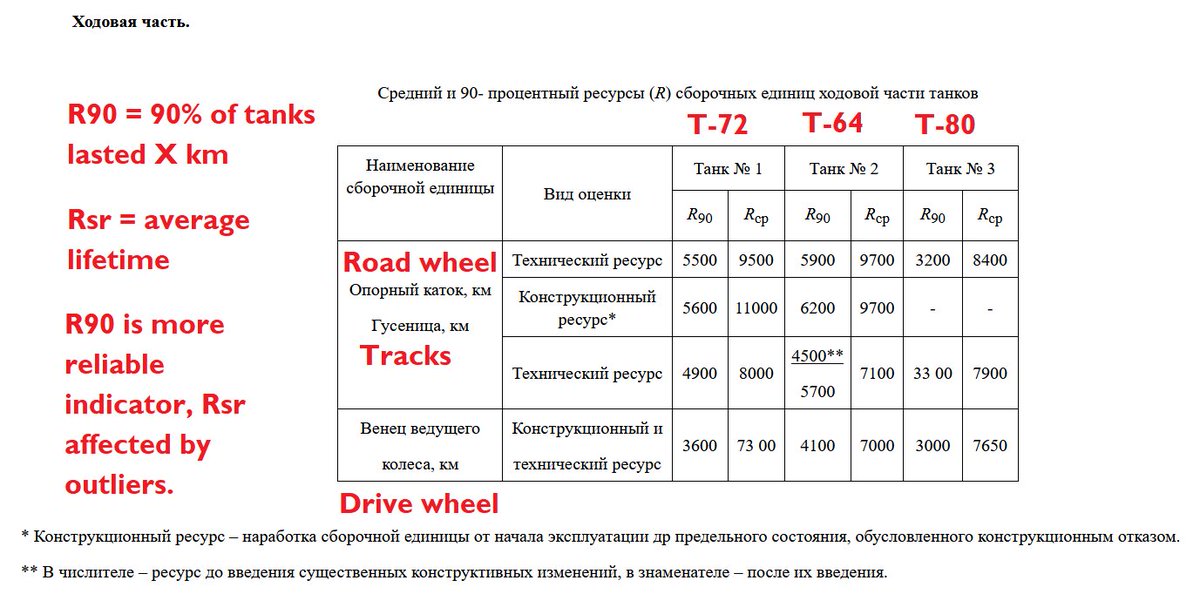

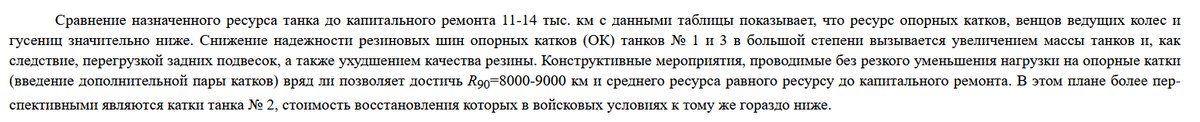

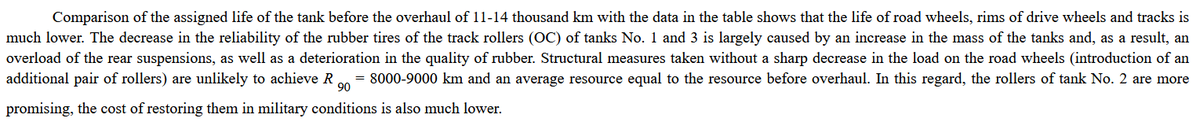

(12/17) It also lasts longer than the rubber tires of the T-72 or T-80, which are the #1 cause of failure of those tanks' suspension.

btvt.info

btvt.info

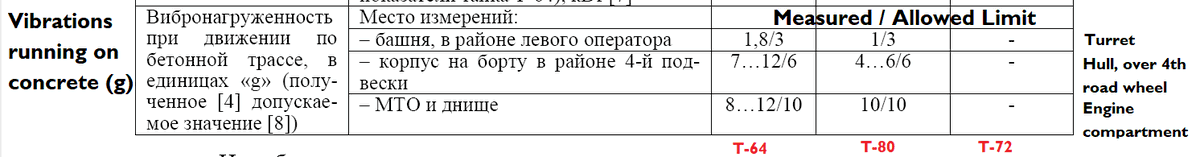

(16/17) According to Shawshank, these vibrations are most harsh when running at 30-40 km/h and cause grease to leak out of the wheels over time. When running on hard roads they must be regreased every 150-200 km.

youtube.com

youtube.com

Oh, and if you believe the big aluminum road wheels add any significant protection to the T-72 or T-80 against anything reasonably powerful, you're welcome to ask the lone survivor of this T-72 his opinion about the T-72's side protection.

youtube.com

youtube.com

Loading suggestions...