2/ While I may not be an expert on shipping, I do have real world engineering experience with designing bunker fuel blending systems and on-shore fuel oil facilities design. So let's get into it.

3/

This thread will have several sections as follows:

(A.) What is bunker fuel?

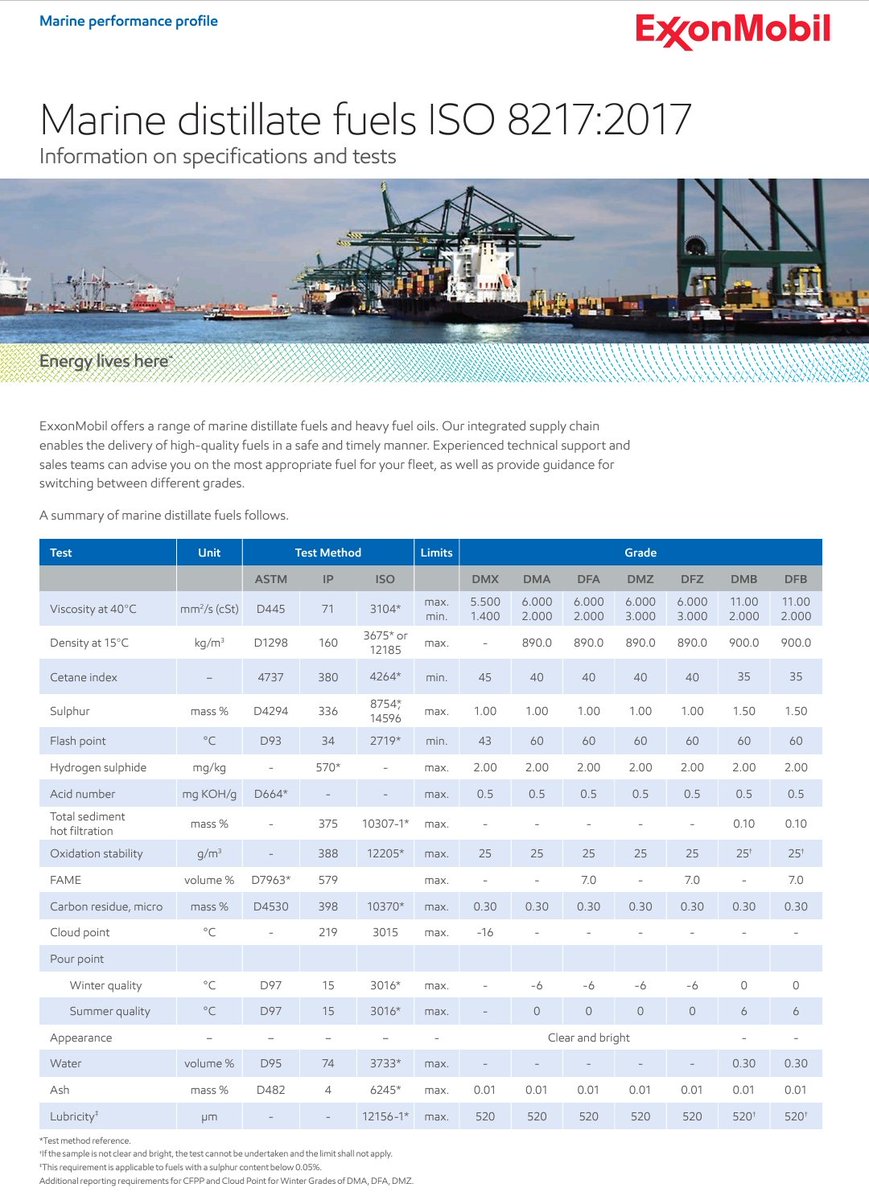

(B.) Bunker Fuel Specifications

& Marine Distillate Fuel specifications

(C.) IMO 2020 regulations and related issues (Sulfur, Lubricity, & Viscosity)

(D.) Fuel Oil Blending Components

This thread will have several sections as follows:

(A.) What is bunker fuel?

(B.) Bunker Fuel Specifications

& Marine Distillate Fuel specifications

(C.) IMO 2020 regulations and related issues (Sulfur, Lubricity, & Viscosity)

(D.) Fuel Oil Blending Components

4/

(E). Bunker Fuel Blending Shenanigans

(F.) Other types of fuel oil

(E). Bunker Fuel Blending Shenanigans

(F.) Other types of fuel oil

5/ (A.) What is bunker fuel?

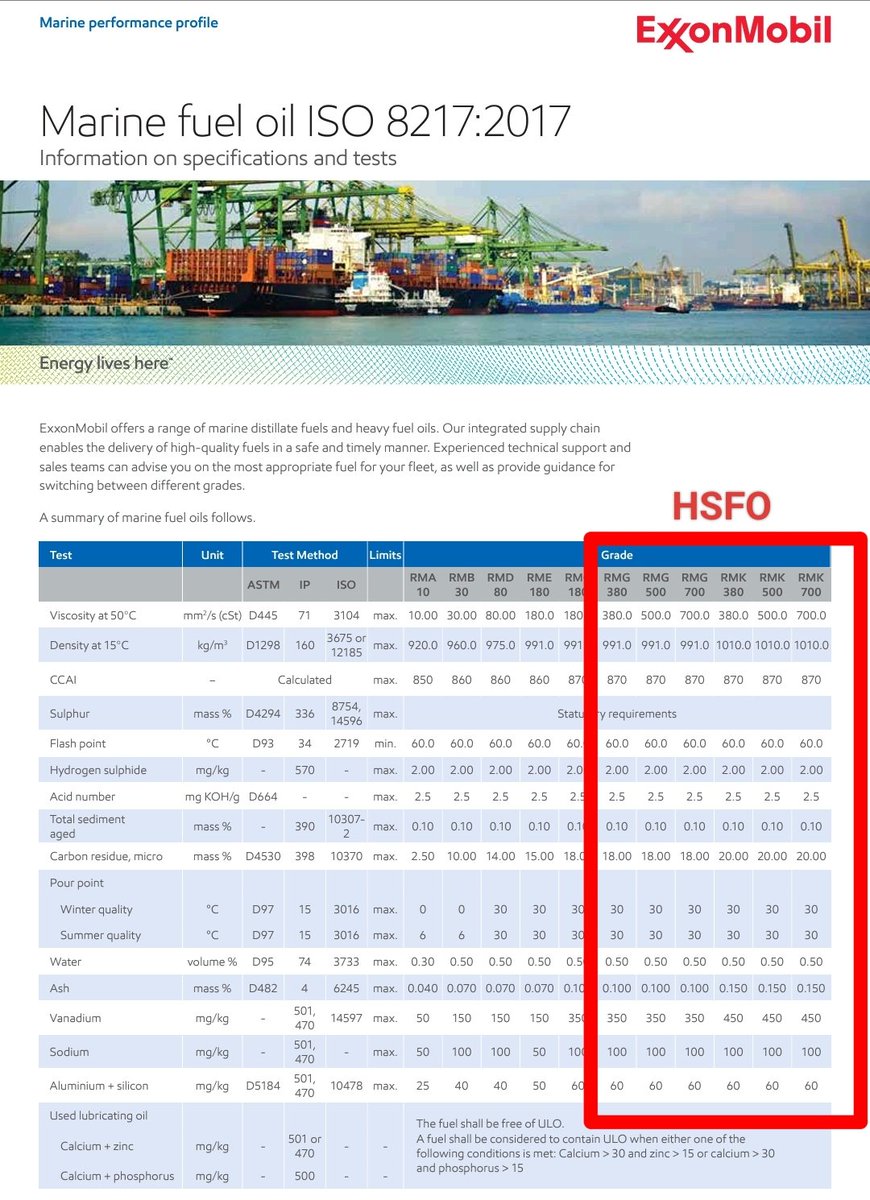

What is bunker fuel? Bunker Fuel also known as "Bunker Fuel C", "Heavy No. 6 Fuel Oil", or for this thread "No. 6", is a heavy hydrocarbon liquid blended from a number of refinery components to meet a certain saleable spec.

mckinseyenergyinsights.com

What is bunker fuel? Bunker Fuel also known as "Bunker Fuel C", "Heavy No. 6 Fuel Oil", or for this thread "No. 6", is a heavy hydrocarbon liquid blended from a number of refinery components to meet a certain saleable spec.

mckinseyenergyinsights.com

7/ The typical practice for making No.6 fuel oil, involves blending vacuum residue (VR) from the Vacuum Distillation Unit (VDU) in a refinery with enough "diluent" to meet the maximum viscosity specification @ 50°C (i.e. 380, 500, or 700 centiStokes, cSt).

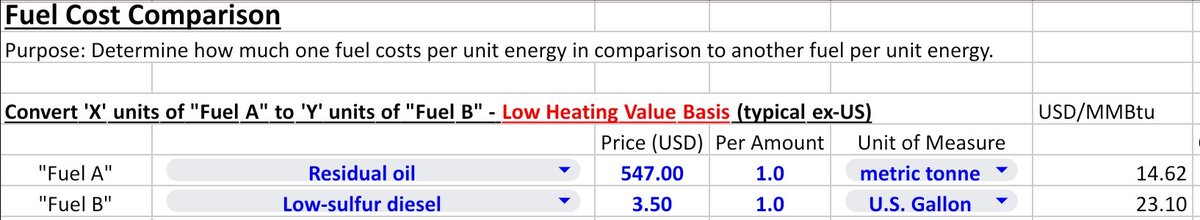

8/ Blenders use as little diluent as possible b/c it's valuable and could be used, either directly or in other refinery processes, to make something else with a higher product margin (like diesel). More on diluent later in section (D.) of this thread 😉

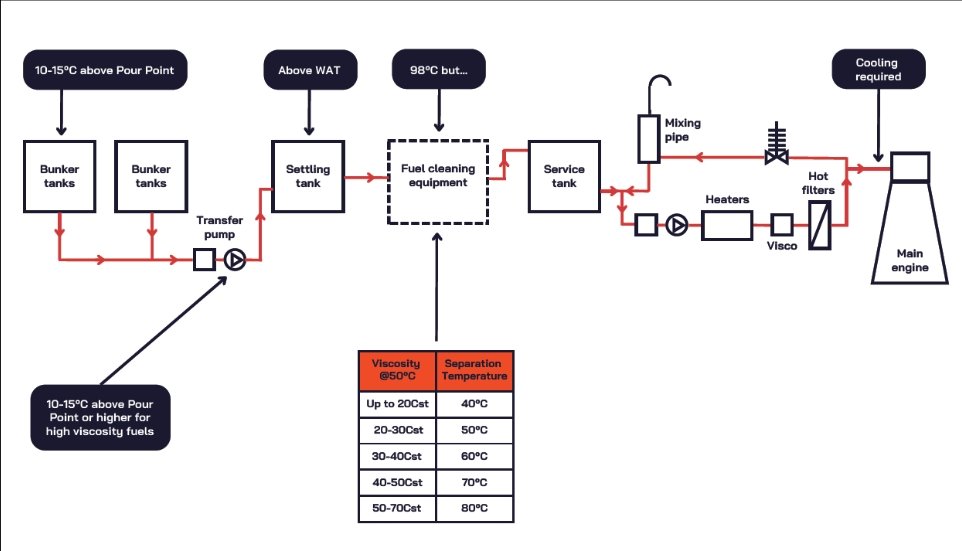

11/ The most important spec is the max viscosity @ 50°C (122°F). For those whose chemistry is a little rusty, viscosity is a measure of the resistance to flow of a liquid due to the intermolecular forces present in the molecules. The viscosity of water is 1.0 cSt @ 20°C (68°F).

12/ Why is viscosity so important? Well contrary to what you might think, liquid doesn't burn. What??? Yep, you read that right! In order for a liquid fuel to burn it must first be transformed into a vapor.

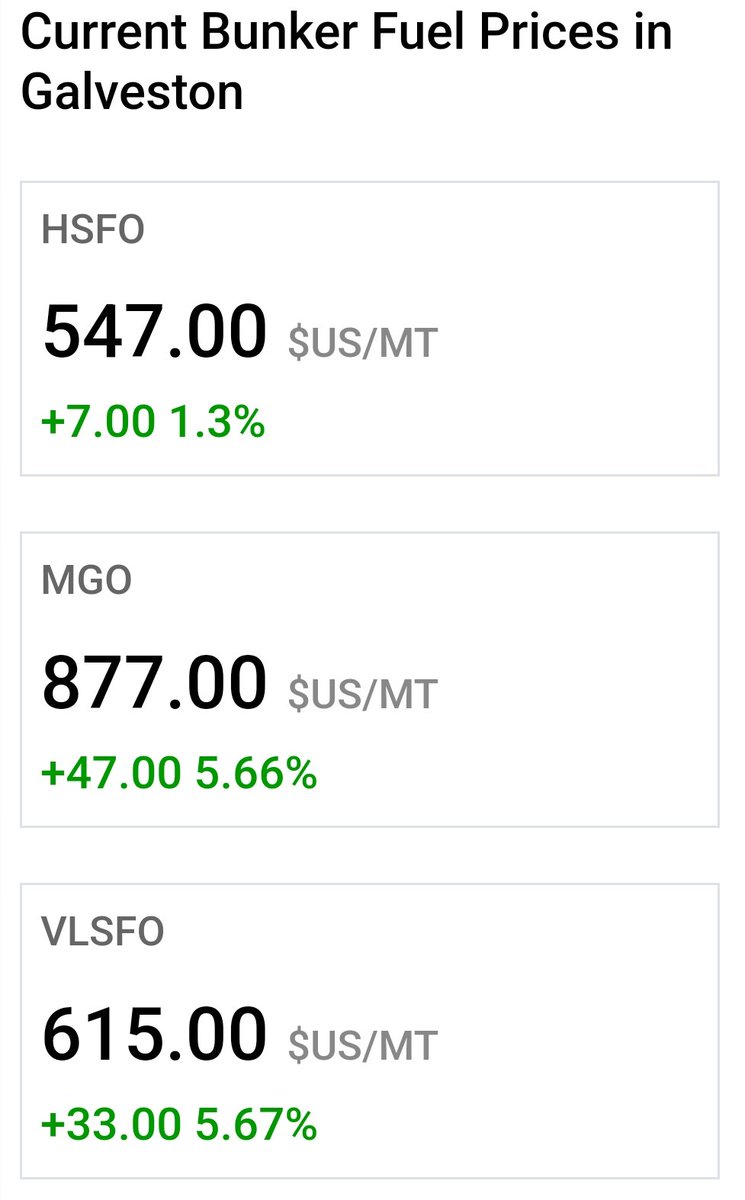

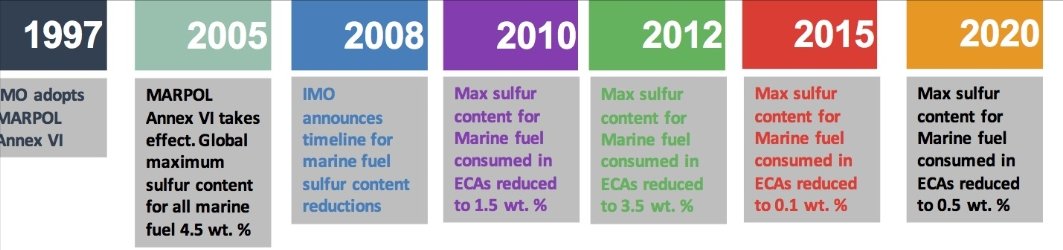

13/ When you light a pool of room temperature gasoline on fire, the gasoline at the top of the pool is vaporized first. In a gasoline engine your fuel injectors create a very fine "atomized" mist, which is then combusted in the cylinders.

14/ Vacuum residue, which is the major component of fuel oil, has been vacuum distilled at an absolute pressure of 20-35 mmHg (vacuum) to a final boiling point of 1,050°F (565°C). Room temperature bunker fuel will easily put out a lit cigarette (so will diesel for that matter!).

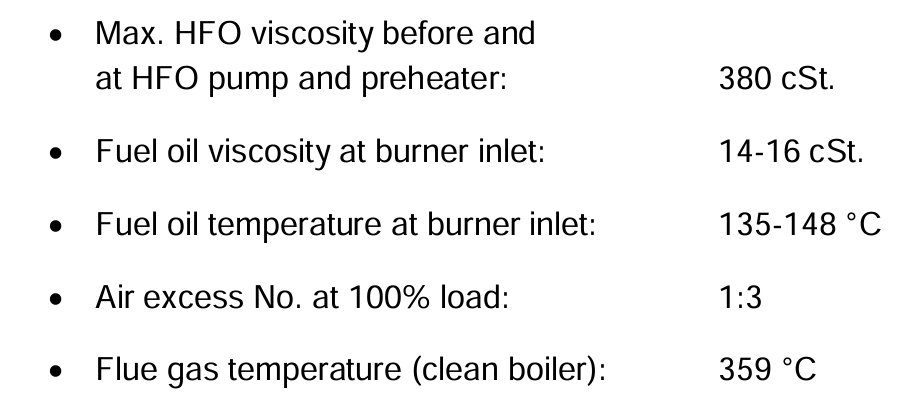

15/ When I've designed onshore fuel oil burning facilities in refineries (boilers, etc.), the ideal viscosity where fuel oil can be atomized for combustion is 25 cSt at the burner tips, right before the combustion happens.

16/ How much heat needs to be applied in the heat exchanger is however much is needed to get the fuel oil to that exact viscosity. This typically requires heating to about 135°C (275°F) at a pressure of 13.8 bar (200 psig).

19/ Too low a viscosity also causes problems with fuel pump pressure, leaks, or vapor lock. More on that here: manifoldtimes.com

20/

Next we have maximum density (mass/volume).

Then we have CCAI, which is a relationship between viscosity and density which serves a reference number for ignition quality, similar to octane for gasoline engines and cetane for diesel engines.

Next we have maximum density (mass/volume).

Then we have CCAI, which is a relationship between viscosity and density which serves a reference number for ignition quality, similar to octane for gasoline engines and cetane for diesel engines.

21/ We'll come back to sulfur in a minute. The other specifications on the first page are all properties that measure fuel quality to ensure safe and problem-free combustion in the ships burners and engines. Don't want too much water in the fuel since water doesn't burn.

22/ Ash, microcarbon residue, vanadium, & sodium are all components which occur naturally in crude oil and cannot be economically removed from the vacuum residue. Hit me up with ANY of your questions about any of these fuel specifications in the comments.

24/ When combusted, all sulfur in the oil turns into sulfur dioxide (SO2), an acute atmospheric pollutant. SO2 smells bad, makes it harder to breathe, sucks if you have asthma or respiratory health conditions, and contributes to acid rain and the acidification of oceans.

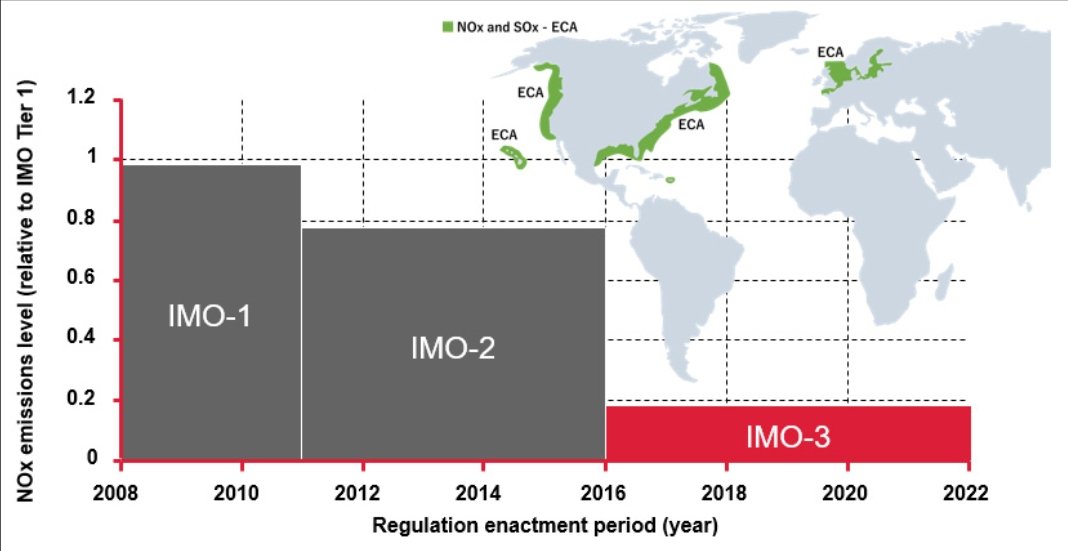

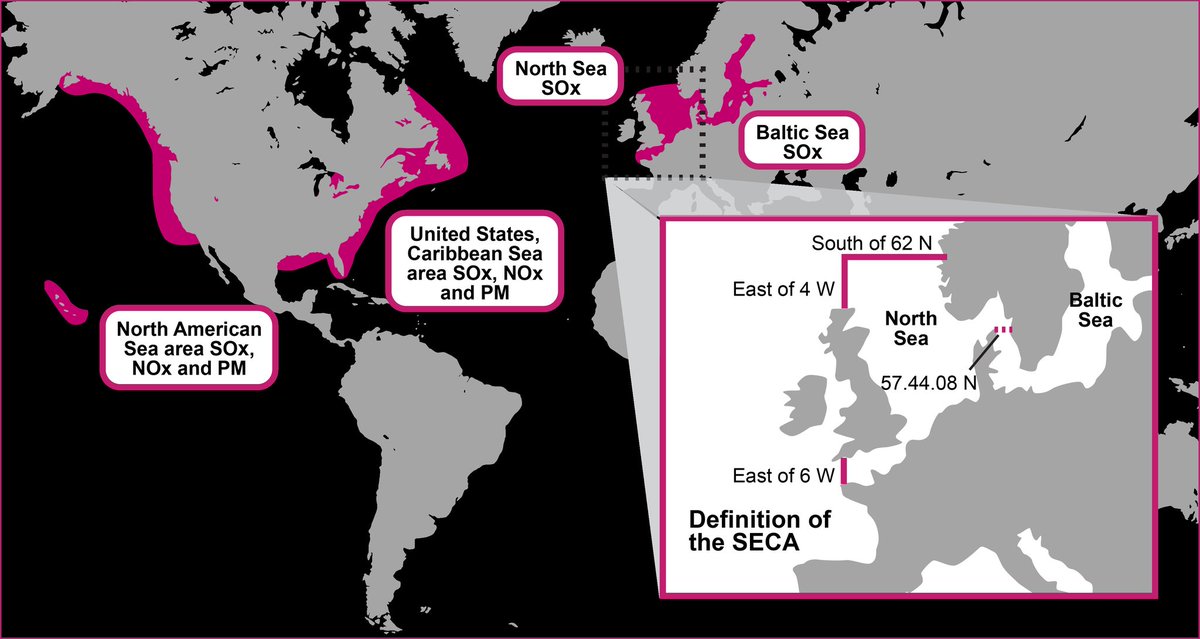

25/ (C.) IMO 2020

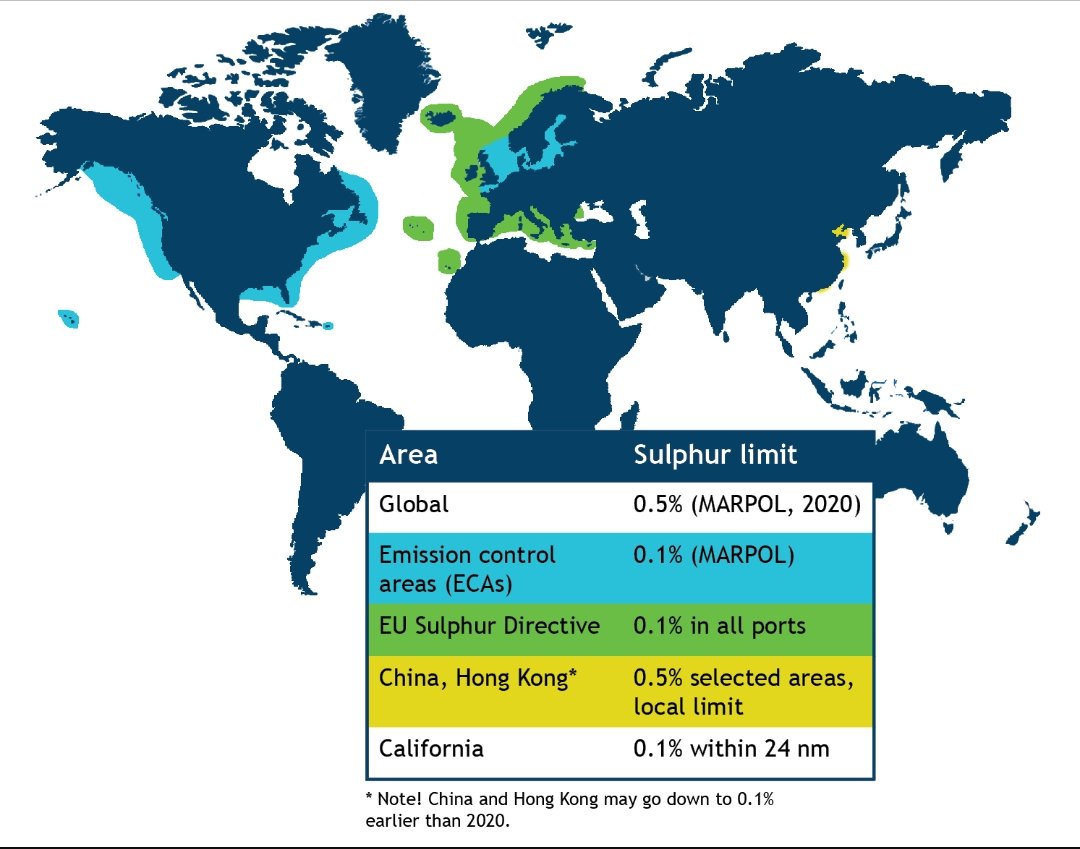

The International Maritime Organization (IMO) is a regulatory agency that, among many other regulations, sets sulfur limits on bunker fuel burned by the world's shipping fleet for those countries that are signatories of it en.m.wikipedia.org.

The International Maritime Organization (IMO) is a regulatory agency that, among many other regulations, sets sulfur limits on bunker fuel burned by the world's shipping fleet for those countries that are signatories of it en.m.wikipedia.org.

26/ There is no EPA on the open ocean, so in an effort to clean up the air around the world's port cities, countries agreed to limit the amount of sulfur allowed in bunker fuel.

28/ Before that, the regulation was 4.5% max, which is relatively close to the amount of Sulfur naturally be present in a fuel oil blend anyway. I've smelled 3.5 wt%S #6 being burned (illegally?) while fishing in Galveston Bay, Texas. It reeks, and you can smell it for miles.

29/ The IMO 2020 regulation put a maximum sulfur content in any fuel burned on a ship at 0.50 wt% sulfur even outside the ECAs. A huge drop! Meeting this regulation was a challenge for shipping and a challenge for refineries as well.

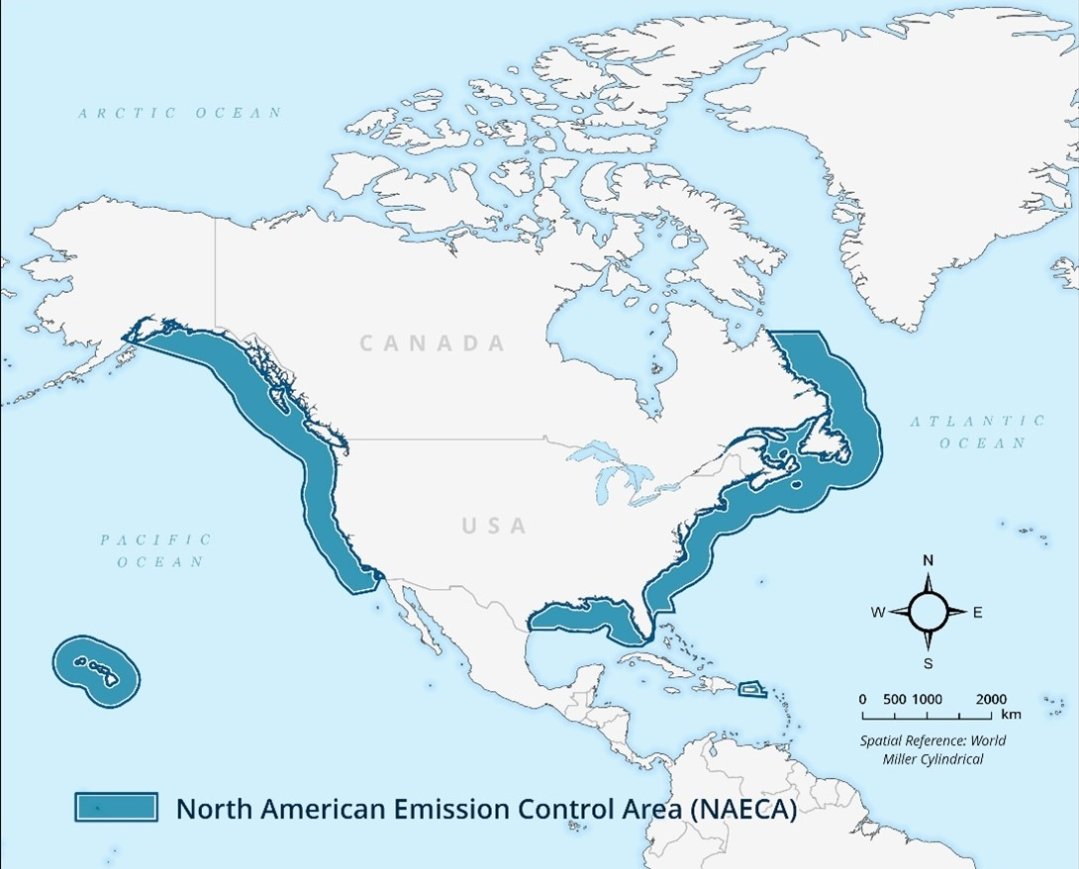

30/ These fuel sulfur regulations have always applied to areas *outside* Emission Control Areas (ECAs). For the USA this always meant roughly 200 nautical miles off the coastal areas.

33/ One of the effects of removing the sulfur from any fuel is that sulfur naturally provides lubricity to the engine cylinders. This same problem was experienced with other efforts to remove sulfur from gasoline and road diesel with ULSD regulations.

34/ And also recently with removing sulfur from jet fuel. In each case the problem of reduced lubricity in engines was overcome by adding lubricity improver additives to the fuel.

35/ Anyone who was surprised by this challange with IMO 2020 didn't do their homework on the history of sulfur removal from fuel 😉.

36/ So if you're a ship how do you comply with this new IMO 2020 spec? You have a few options:

37/

1. Install a scrubber to remove the SO2 from the flue gas coming out of the combustion stack. This costs millions of dollars in capital cost invested in the equipment on the ship (which also takes up valuable space). But it's a one-time investment.

1. Install a scrubber to remove the SO2 from the flue gas coming out of the combustion stack. This costs millions of dollars in capital cost invested in the equipment on the ship (which also takes up valuable space). But it's a one-time investment.

38/

2. You can switch to burning 0.5 wt%S VLSFO. Lower capital cost, higher operating cost...in perpetuity.

3. Fuel switching retrofit. Burn some other fuel that meets the regulation, such as LNG. This is the highest capital cost option of all. Rarely done on existing ships.

2. You can switch to burning 0.5 wt%S VLSFO. Lower capital cost, higher operating cost...in perpetuity.

3. Fuel switching retrofit. Burn some other fuel that meets the regulation, such as LNG. This is the highest capital cost option of all. Rarely done on existing ships.

39/ But fuel switching is potentially attractive on new ships. You see this in recent ship orders.

40/ (D.) Bunker Fuel Blending Components

As mentioned, No. 6 is made with VR and diluent. What can refineries use as diluent? The answer is pretty much anything they want as like no as the final blend meets the specifications.

As mentioned, No. 6 is made with VR and diluent. What can refineries use as diluent? The answer is pretty much anything they want as like no as the final blend meets the specifications.

41/

In practice the following components are typically used:

(i). Light Cycle Oil (LCO) from the Fluidized Catalytic Cracker (FCC). Disadvantage: Diesel blending component

Advantage: None

mckinseyenergyinsights.com

In practice the following components are typically used:

(i). Light Cycle Oil (LCO) from the Fluidized Catalytic Cracker (FCC). Disadvantage: Diesel blending component

Advantage: None

mckinseyenergyinsights.com

42/

(ii.) Unconverted Oil (UCO) from the Hydrocracker Unit (HCU)

Disadvantage: Also FCC feedstock (iff you also have one) or Lube Oil feedstock (iff you make lube oil). Advantage: Can make VLSFO b/c the HCU removed the Sulfur already.

mckinseyenergyinsights.com

(ii.) Unconverted Oil (UCO) from the Hydrocracker Unit (HCU)

Disadvantage: Also FCC feedstock (iff you also have one) or Lube Oil feedstock (iff you make lube oil). Advantage: Can make VLSFO b/c the HCU removed the Sulfur already.

mckinseyenergyinsights.com

43/ (iii.) Light Coker Gasoil (LCGO) from the the Delayed Coker Unit (DCU).

Disadvantage: Diesel blending component. You came all this way are now you're going to waste this???

Advantage: None? (Maybe don't have to hydrotreat it iff you're making HSFO).

Disadvantage: Diesel blending component. You came all this way are now you're going to waste this???

Advantage: None? (Maybe don't have to hydrotreat it iff you're making HSFO).

45/

(iv.) Main Column Bottoms (MCB) from the FCC.

Disadvantage: Also feedstock to (iff you have one) the DCU, where you can turn it into gasoline, diesel, and feedstock to the HCU to make more of the same. Also issues with catalyst fines, may be limited on amount you can blend.

(iv.) Main Column Bottoms (MCB) from the FCC.

Disadvantage: Also feedstock to (iff you have one) the DCU, where you can turn it into gasoline, diesel, and feedstock to the HCU to make more of the same. Also issues with catalyst fines, may be limited on amount you can blend.

46/

(iv. cont'd) Advantage: If you don't have a DCU, fuel oil is the best place for it.

digitalrefining.com

(iv. cont'd) Advantage: If you don't have a DCU, fuel oil is the best place for it.

digitalrefining.com

47/

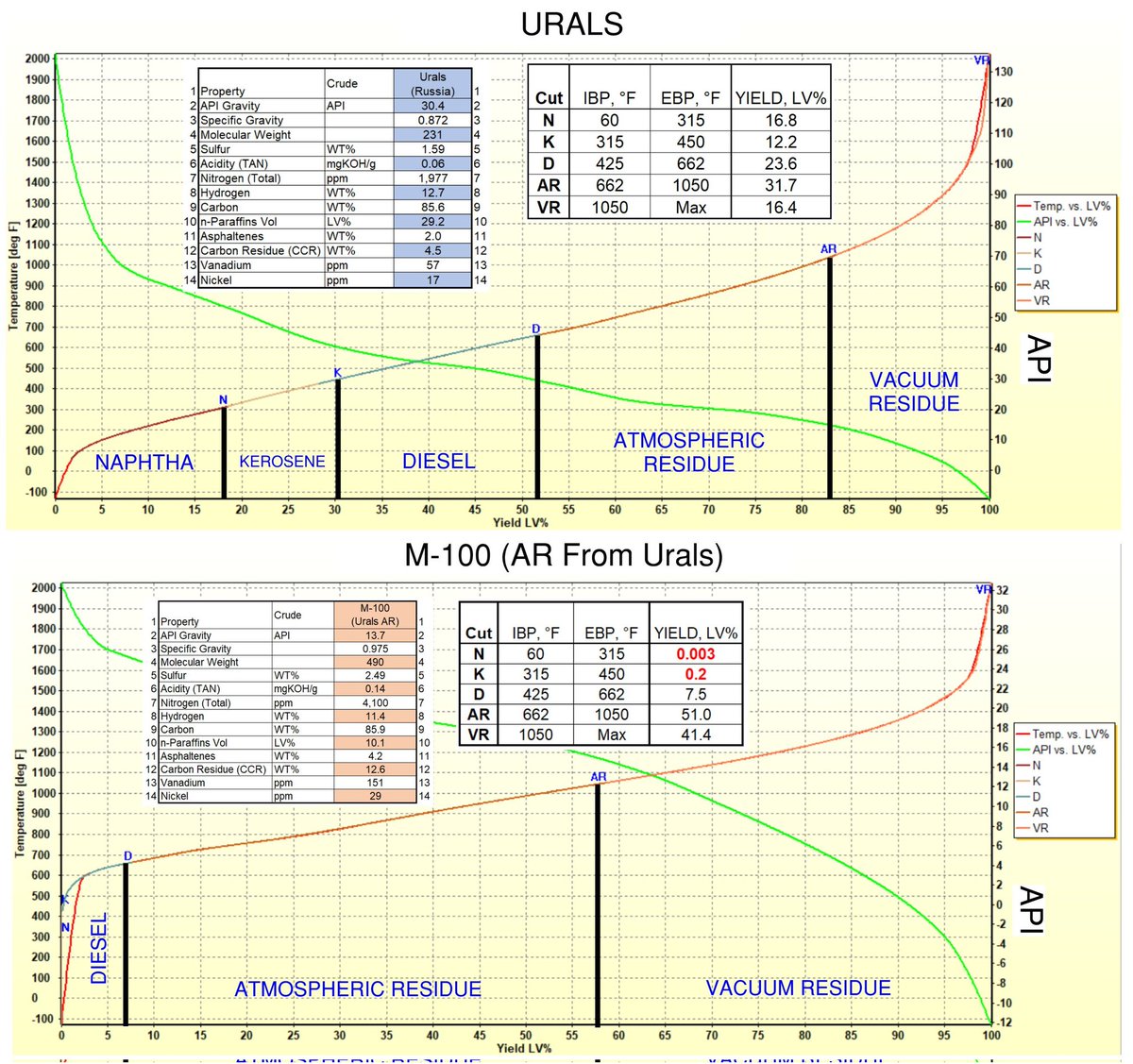

(v.) Is that it? No, you can blend almost anything including a combination the above, as long as you meet the spec. The trick is doing it economically. The Russians use Atmospheric Residue (AR) from the bottom of their atmospheric distillation column, also known as "M-100".

(v.) Is that it? No, you can blend almost anything including a combination the above, as long as you meet the spec. The trick is doing it economically. The Russians use Atmospheric Residue (AR) from the bottom of their atmospheric distillation column, also known as "M-100".

48/

They're pretty much the only ones I know of who do this because their Urals AR meets the HSFO specs. This lets them maximize the straight-run diesel product without expensive refinery investments.

They're pretty much the only ones I know of who do this because their Urals AR meets the HSFO specs. This lets them maximize the straight-run diesel product without expensive refinery investments.

Taking a break for X-mas Eve dinner. Will resume later tonight.

50/ These refineries were designed to run heavy crude. M-100 AR backfilled this for us, for a time. This disruption in supply chain was partially responsible for the diesel crunch we had the last couple of years.

51/

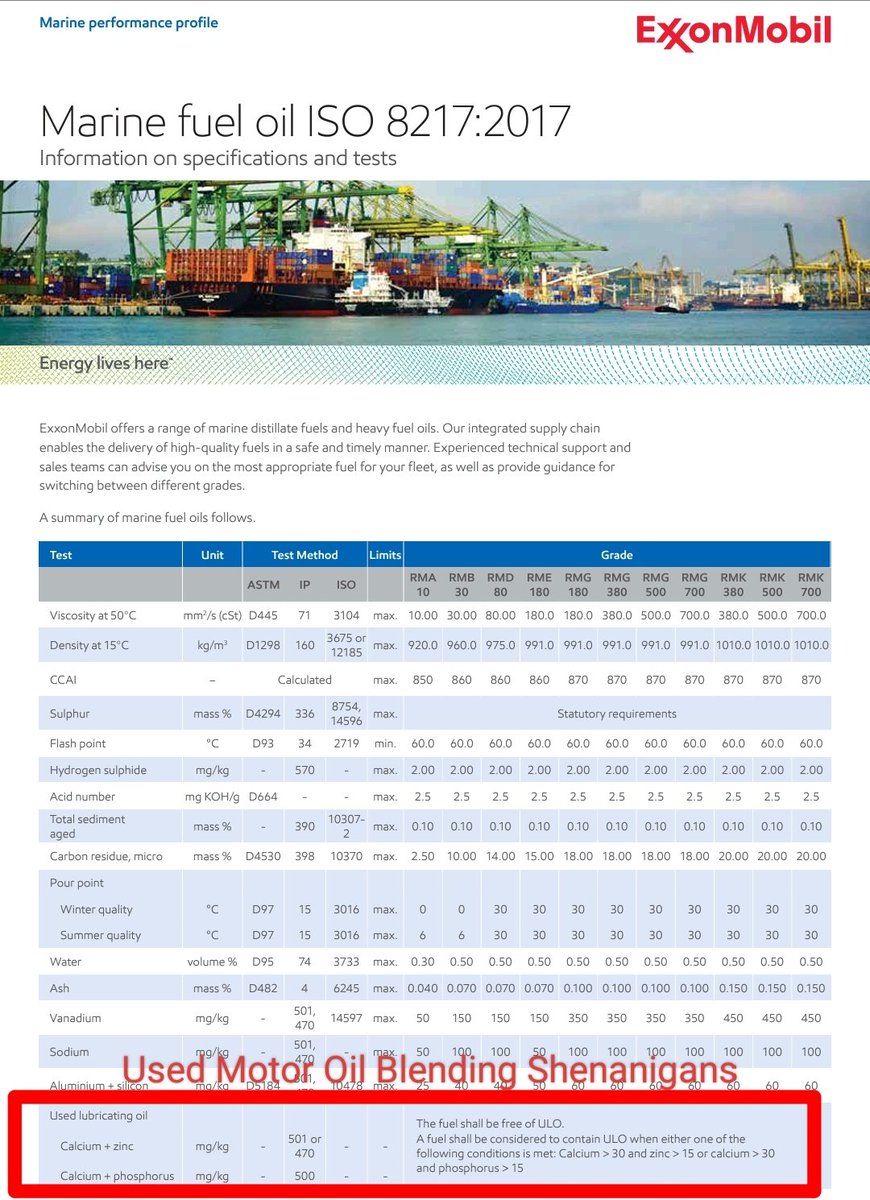

(E.) Bunker Fuel Blending Shenanigans 🤣 (still writing this one)

(E.) Bunker Fuel Blending Shenanigans 🤣 (still writing this one)

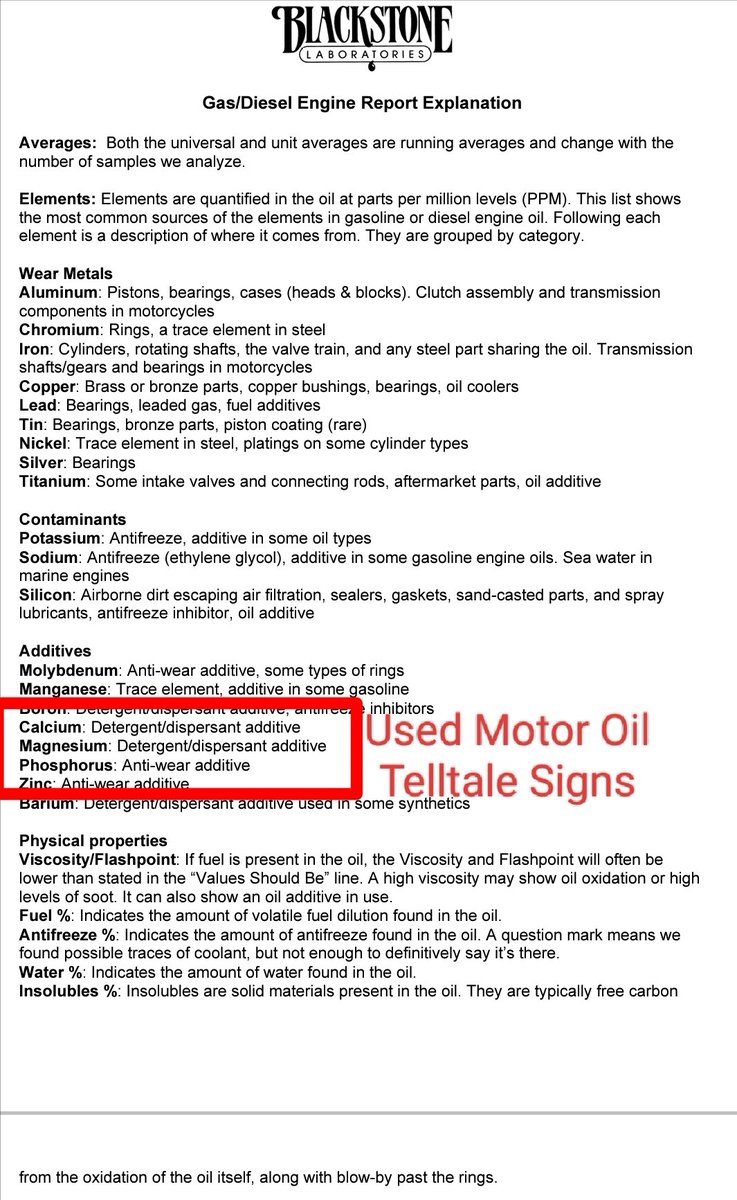

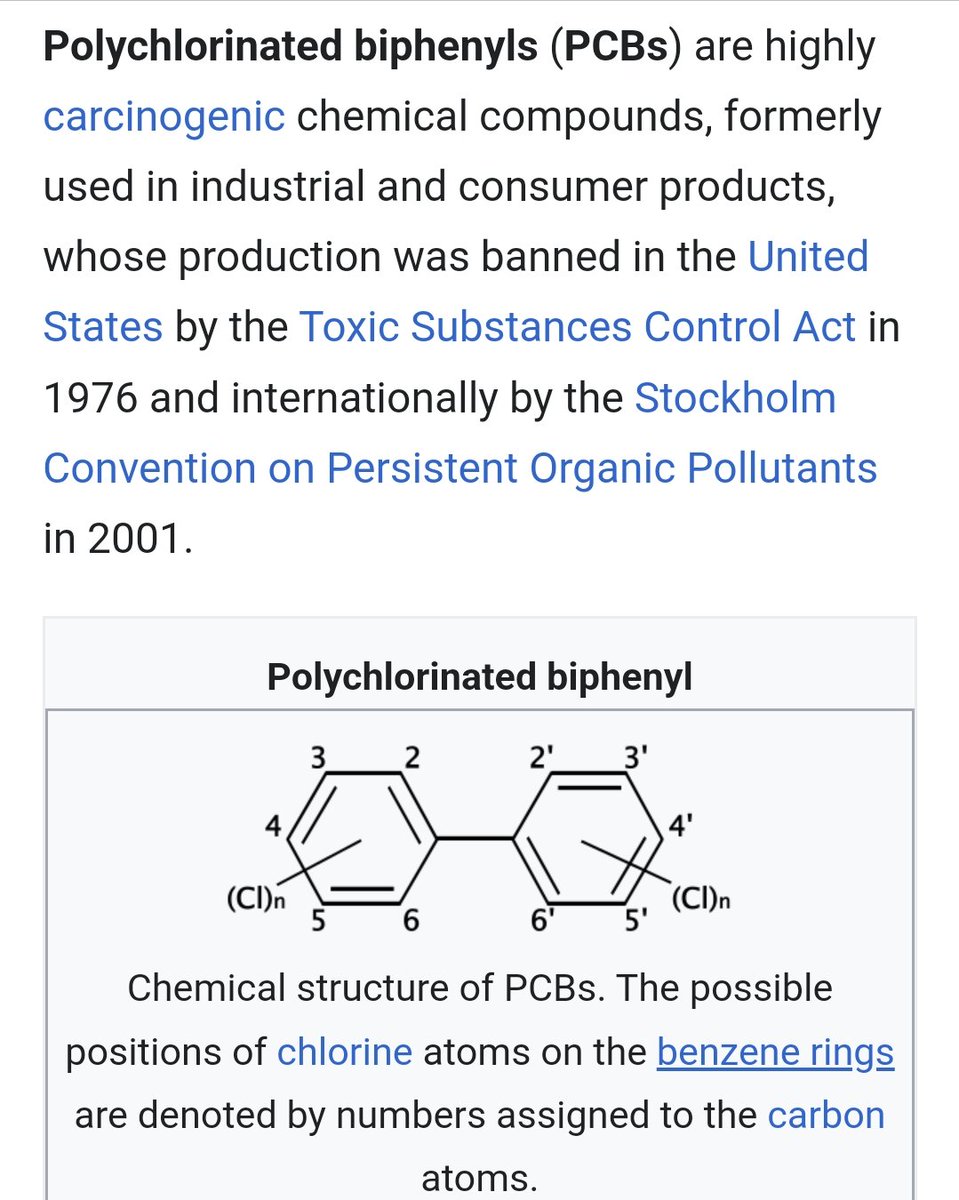

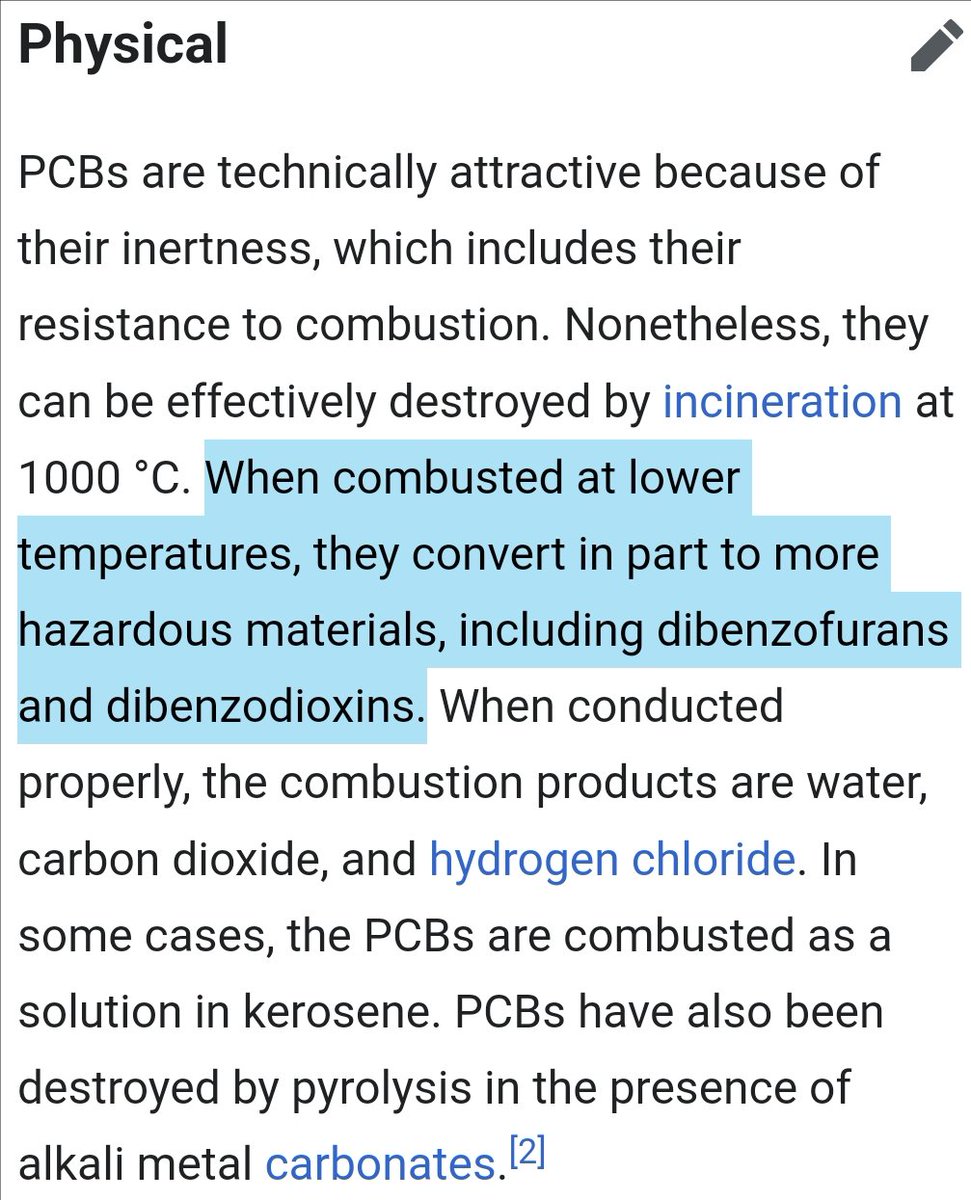

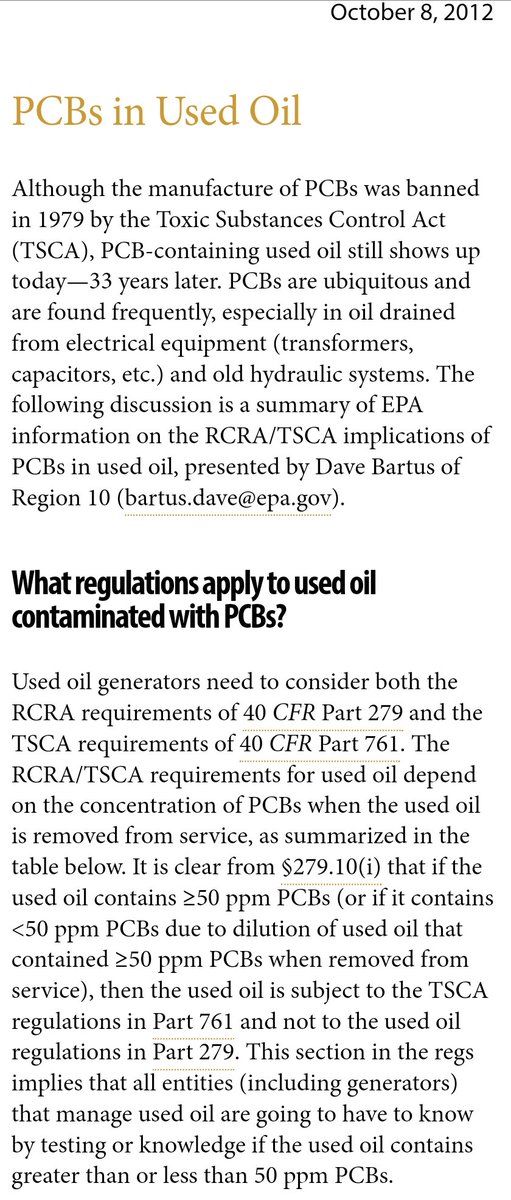

52/ I said previously you can blend pretty much anything into bunker fuel as long as it makes the spec. One thing that *is* frowned on, is used motor oil. The incentive for blenders is that the feedstock is almost free. Blending into No. 6, turns it into a saleable product.

56/ All this despite the fact that PCBs were outright banned forty-five (45) years ago!

mccoyseminars.com

mccoyseminars.com

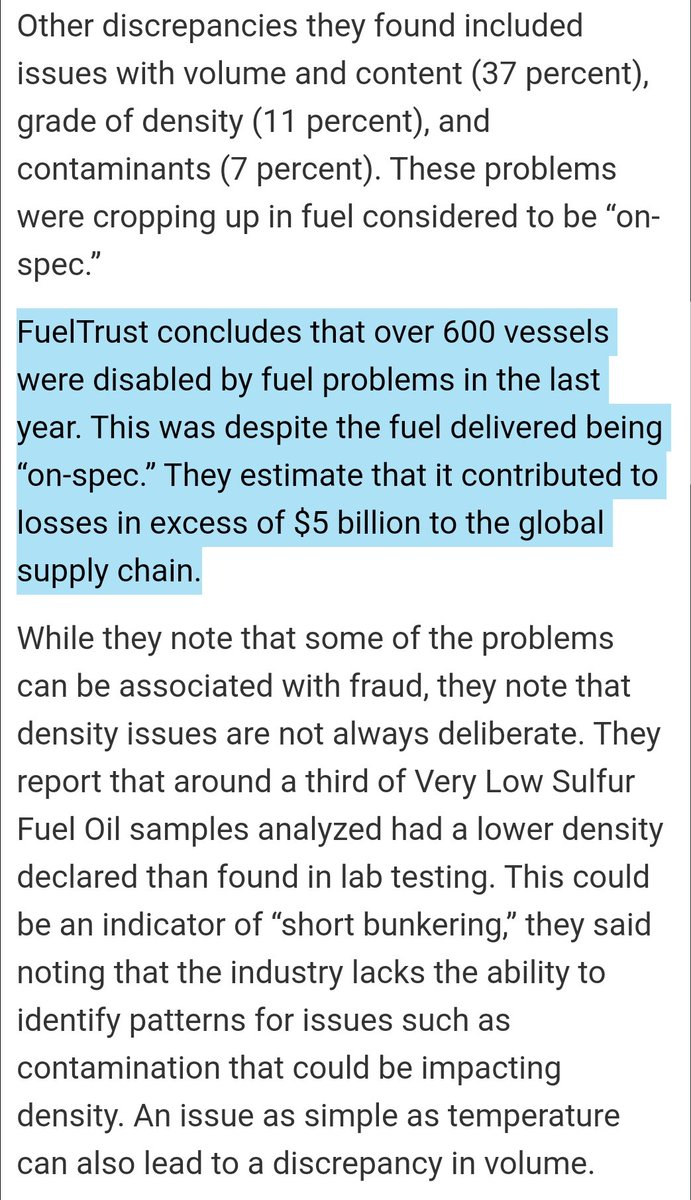

57/ Bunker fuel blending problems of any type are serious if you're on a ship. If the ship loses power, it's adrift in the ocean, potentially in the dark. Bunker fuel blending problems can affect all grades of fuel, from No. 6 HSFO to VLSFO. maritime-executive.com

60/ (F.) Other types of fuel oil not used in shipping. I'm going to let this article from ANSI / ASTM do the work here: blog.ansi.org

61/ FIN! Merry Christmas🎄 Everyone. Thanks for reading! Especially those that made it to the end 🙌. Hope you enjoyed it. Feel free to ask questions.

Tagging some Twitter/X friends and people I follow and respect. Think about following them too. #COM #OOTT #EFT #ShipTwit

@ed_fin @mintzmyer @christankerfund @JoeBeattie11 @ManchesterUtd81 @AhmedBa44329064 @ds @WhiteTundraSG @RazorOil @SHOPGod2 @Mining_Atoms @johnkonrad

@ed_fin @mintzmyer @christankerfund @JoeBeattie11 @ManchesterUtd81 @AhmedBa44329064 @ds @WhiteTundraSG @RazorOil @SHOPGod2 @Mining_Atoms @johnkonrad

Loading suggestions...