#ULTRAMARINE & PIGMENTS LTD - It operates in 4 segment. 1-pigments - one of the major manufacture of ultramarine blue pigment and other pigments. 2-surfactants 3. Detergents powder/liquid

Its own brand name OOB ( mostly in south India ). 4-ITeS/BPO division with specialisation primarily in content management, publishing, hospital billing services etc.

UPL also earns small revenue from its windmill division. It has a capacity 6,000 MTPA in pigments segment and 2,8000 MTPA in surfactant

UPL has its manufacturing facilities at Ambattur, Chennai and Ranipet in North Arcot, Tamil Nadu.

UPL has its manufacturing facilities at Ambattur, Chennai and Ranipet in North Arcot, Tamil Nadu.

Ultramarine blue pigment has diverse application with high-grade pigments used in industries such as plastics, paints, coatings, cosmetics, foods, detergents etc.; lower grade pigments are primarily used for whitewashing and laundry applications.

Global ultramarine pigment growth is expected to increase with CAGR of 4%. it’s Laundry segment is not growing so now company is focusing to growing products and in the fy 20 only company started product shift

So in Ranipet plant they are reducing capacity of Linear alkyl benzene sulphonic acid ( LABSA) which is used in house hold detergent and increasing capacity of Sodium lauryl sulphate used in shampoo( see shampoo bottles) shaving cream , liquid hand soap and many other uses also.

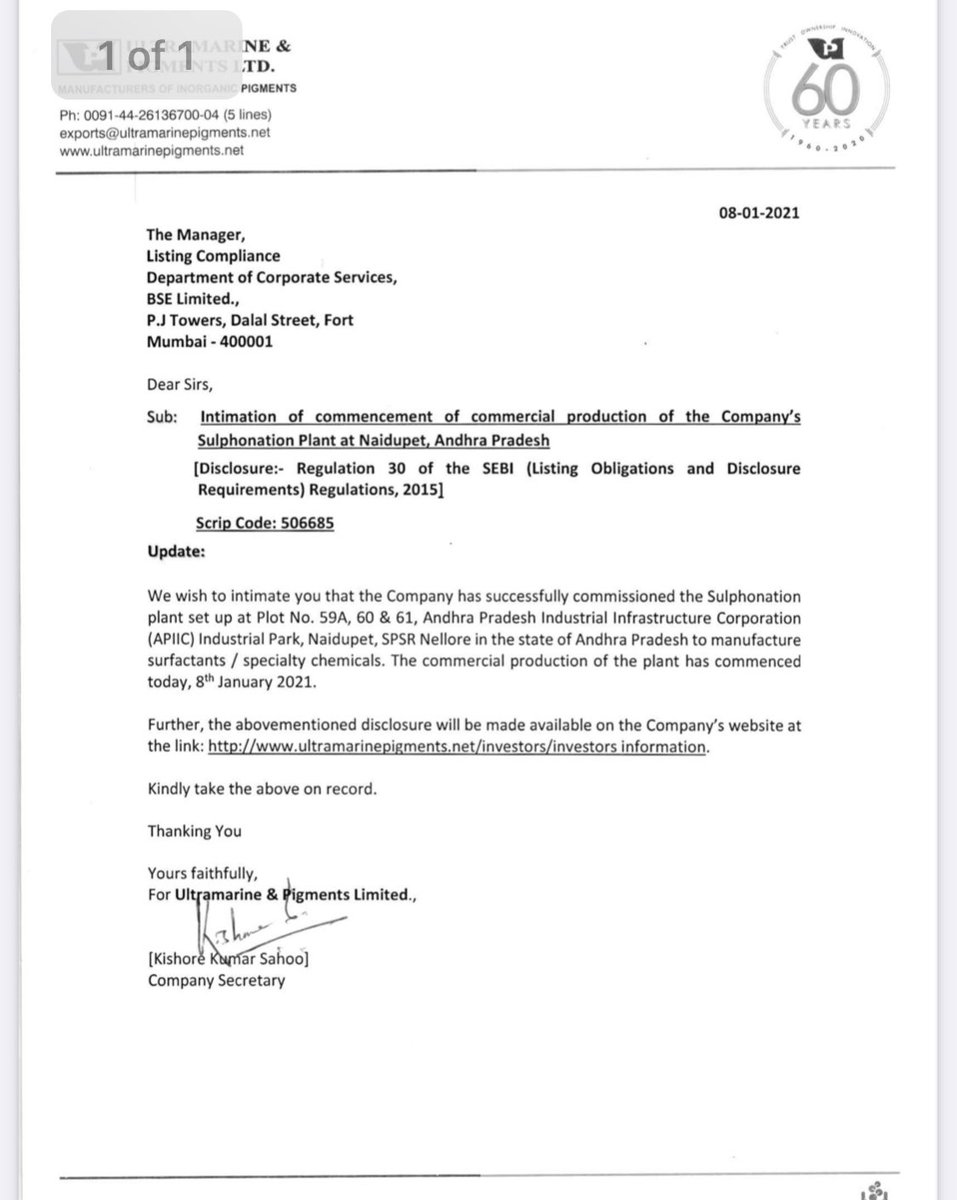

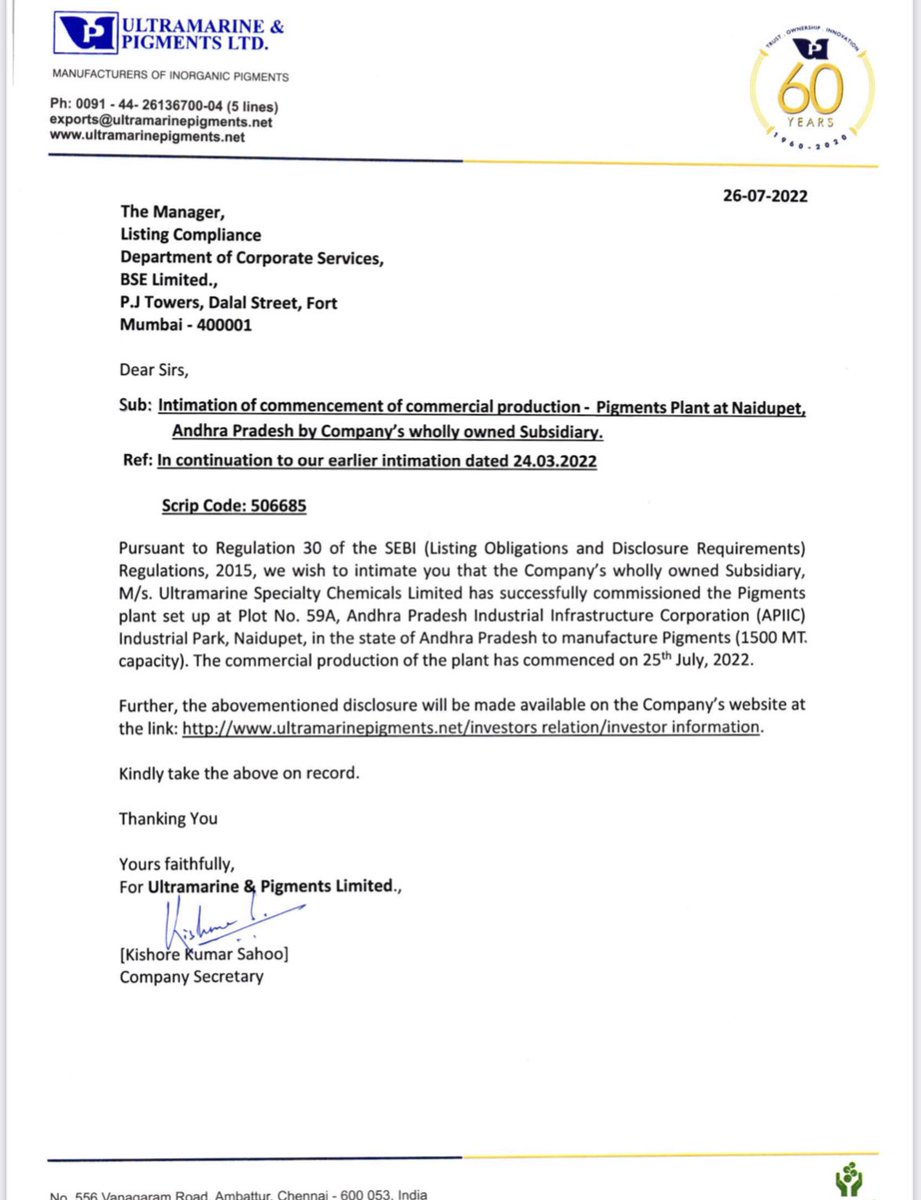

So this product shift will increase their margins and revenue both . Surfactant division is running with full capacity and expansion is going on at new plant at Naidupetta ( Andhra Pradesh ) and probably in next 6 months to 12 months it will be completed.

In Naidupetta capacity addition will be 40000 MPTA (surfactant)in phase 1 and after completion of phase 1 expansion of phase 2 is proposed where speciality surfactant 7500 MPTA And inorganic pigment capacity of 8400 mpta will be added.

Company is paying dividend regularly and having around 20% holding in Thirumalai Chemicals,( almost 90 Cr as of today ) with its own MCAP of 520 Cr as of today with PE of 8.39 and debt around 30 Cr

Galaxy surfactant is trading at PE of more then 25 and now going onward the way UPL is focusing on surfactant it may command high PE This is what I know please provide your inputs also

@threadreaderapp unroll

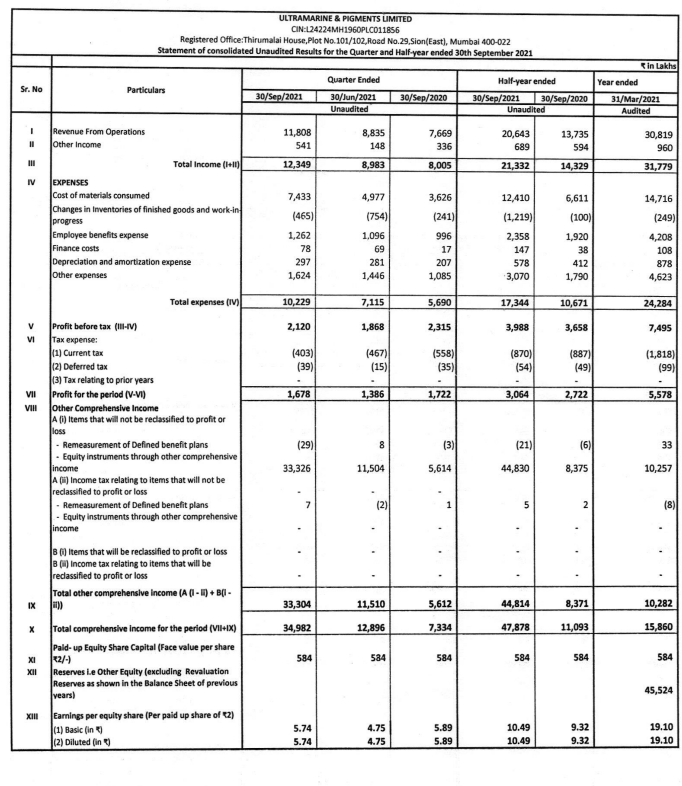

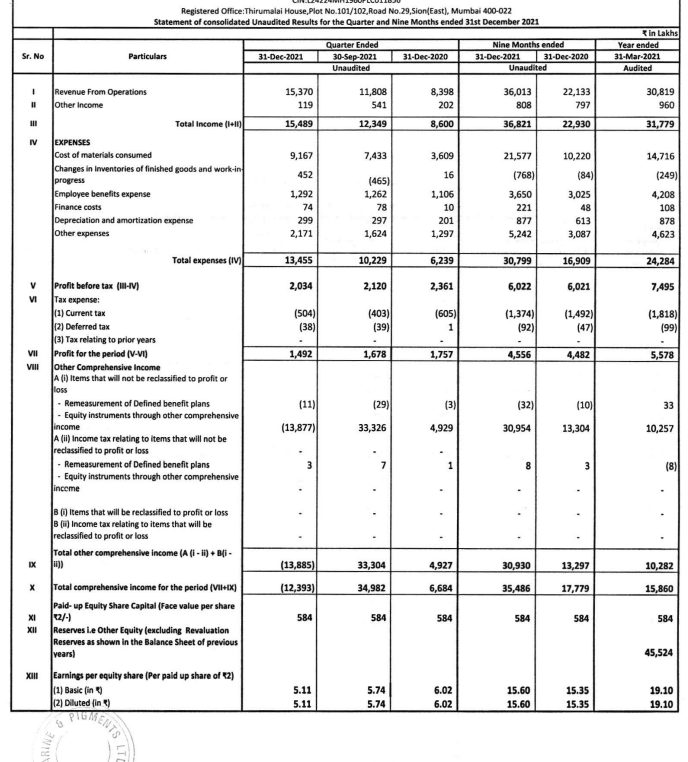

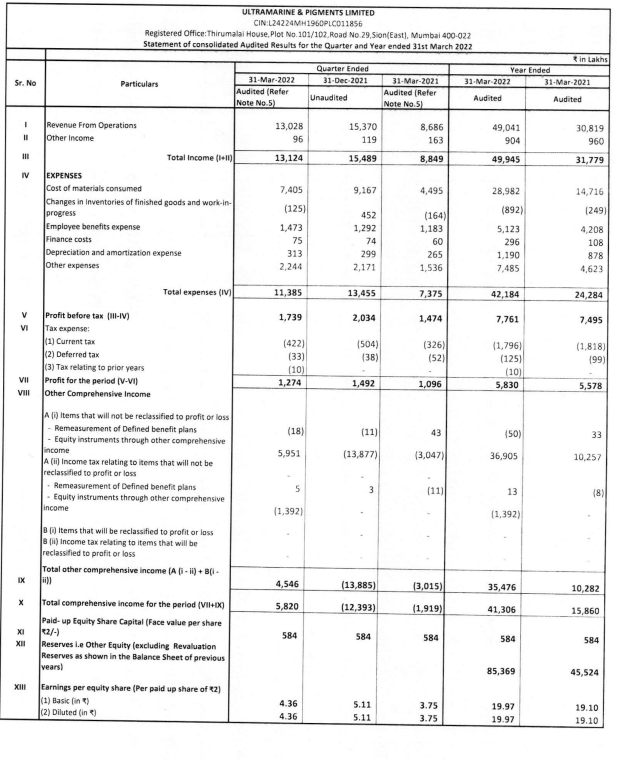

Ultramarine AR

Surfactants Division - continues to achieve 100% capacity utilisation at Ranipet Plant.

The Naidupeta plant

was commissioned on 8th January, 2021

Surfactants Division - continues to achieve 100% capacity utilisation at Ranipet Plant.

The Naidupeta plant

was commissioned on 8th January, 2021

. This is Ultramarine & Pigments, first plant outside Tamil Nadu, and strengthens its commitment to growth and expansion. This is a state-of-the-art plant capable of producing multiple sulphonated products, with a quick turnaround.

Implementation of a green field project to manufacture premium grade Pigments through a 100% subsidiary at Naidupeta has gathered momentum. This project involves a capital outlay of ` 67 Crores.

Upon

implementation, this facility will help meet the market demand for fine grade pigments, reduce the Pigments

division’s operation cycle and contribute to a better profit margin. It is likely to commence operation in the

third quarter of this year.

implementation, this facility will help meet the market demand for fine grade pigments, reduce the Pigments

division’s operation cycle and contribute to a better profit margin. It is likely to commence operation in the

third quarter of this year.

Pigments: The water consumption reduced to 7. 4 KL from 17.6 KL per MT of pigment production. Fossil

fuels were replaced with Liquid Natural Gas (LNG) in Ranipet and conversion is underway in Ambattur. The

energy cost expected to reduce by 25%.

fuels were replaced with Liquid Natural Gas (LNG) in Ranipet and conversion is underway in Ambattur. The

energy cost expected to reduce by 25%.

The yield of the product has improved by 3% hence reduction in usage of Raw materials.

Surfactant: The plant is operated with ZLD, the entire water used for cleaning is treated and recycled back to

the process for dilution. Considerable reduction in energy by 12% over past 4yrs

Surfactant: The plant is operated with ZLD, the entire water used for cleaning is treated and recycled back to

the process for dilution. Considerable reduction in energy by 12% over past 4yrs

Loading suggestions...