But wait…What’s special in a foundry business? There are apparently 5000 foundry units in India, 90% of them can be classified as MSME and 70% are of grey cast iron.

Let's find out what's special about ACL (if any)

Let's find out what's special about ACL (if any)

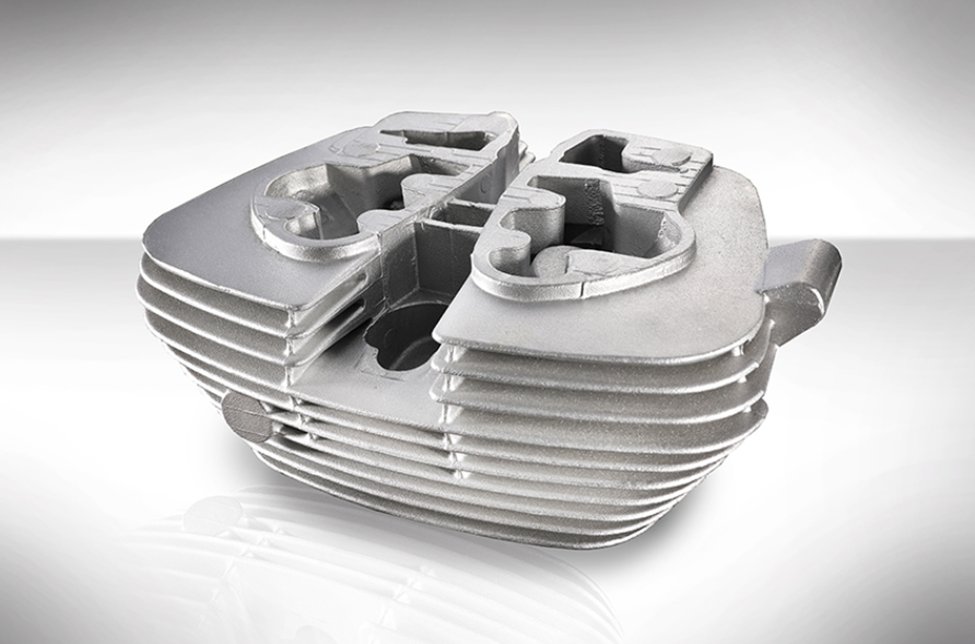

With the BS-VI regime, ACL is also supplying its customers with suspension parts, wheel hubs, bridge fork top, outer tubes and inlet pipes, in addition to cylinder heads. This provides more 'Alicon content per vehicle' to ACL.

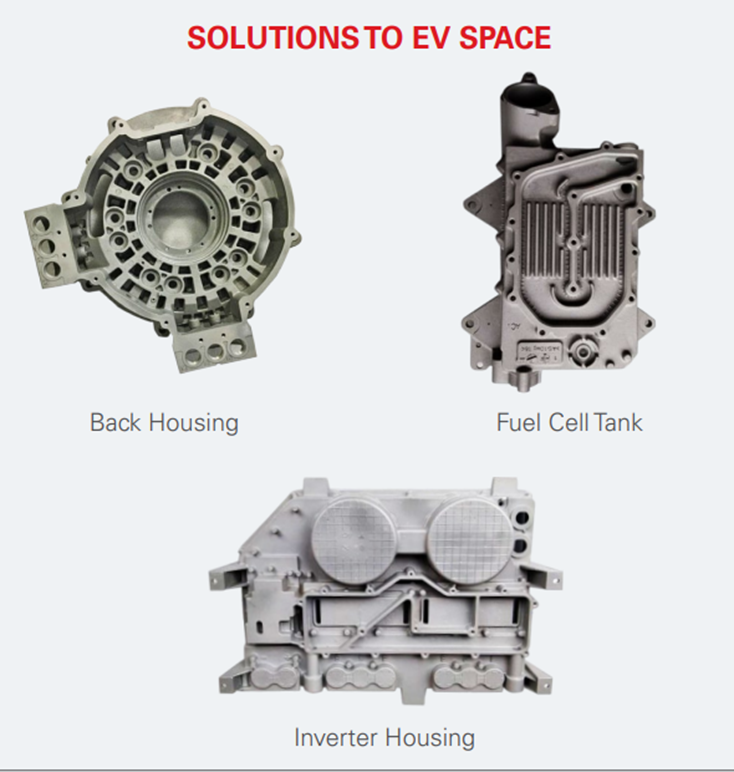

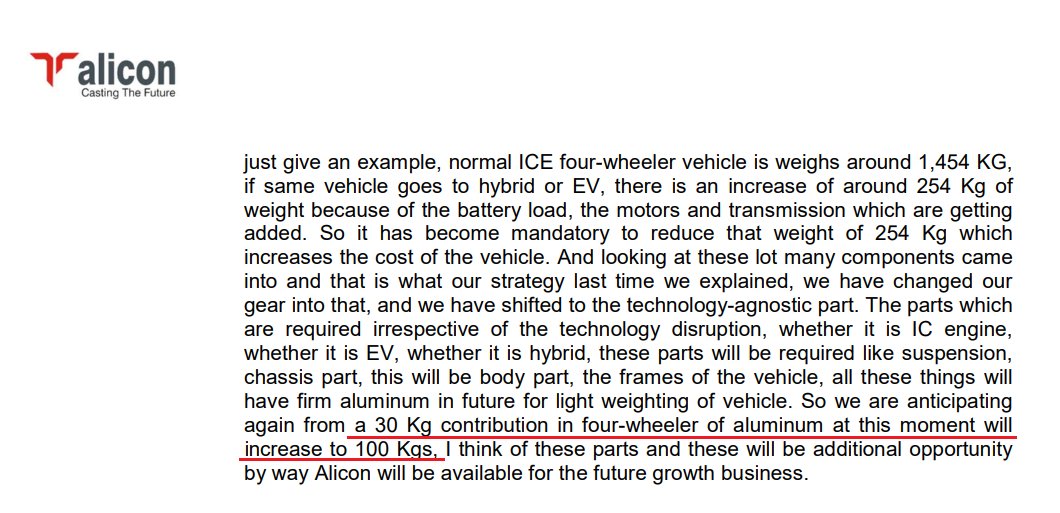

Aluminium and other low-density materials enable a weight reduction of the component as much as 46%, enabling EV efficiencies. Additionally, as vehicles are converted from ICE to EV platform, it is anticipated that aluminium usage will see a 2-2.5-fold increase per vehicle.

ACL is already supplying battery housing to Samsung who supply onward to JLR in the EV space. ACL has also received orders from Dana Corporation, Mahindra & Mahindra, Graziano and Ashwood for their e-mobility platforms.

3) Non-Auto Business: Die casting has found viability in multiple sectors ex. Indian defence sector refurbishing tank wheels with lightweight aluminium parts to lower the tank’s overall weight. Armed with Low-Pressure Die Casting process, ACL is the only Indian supplier.

ACL is also supplying cylinder heads for defence trucks. In agriculture, ACL’s aluminium components are being used by tractors.

4) Technology Agnostic Solutions: Whether platform is ICE, EV or Hybrid, some components remain technology agnostic. Ex. material chassis and suspension components in ICE earlier made in forged steel are now being made in aluminium due to increasing focus towards lightweight EVs.

5) Solution Provider: ACL has devised a thermal engineering solution for EVs that helps alleviate extreme heating in motors and batteries. ACL has partnered with Bosch and Samsung/ e-mobility technology leaders for these thermal management solutions.

ACL has also collaborated with Dana Corporation, a leading global supplier of electrified propulsion systems to develop ready-to-use technology. Such value-enhancing offerings make ACL the preferred partner of choice for customers across their ICE and EV initiatives.

🔍Huge orderbook: Company’s target share of EV business by 2025 is 36% (45% aspirational). It has been working with OEMs and tier-1 suppliers for scaling up EV business. Already have 65 parts related to EV in the portfolio.

Tata Auto comp who is supplying battery packs and motors for EV platform to Tata motors, used to source components from China, now has turned to Alicon with a new order worth 150 cr.

Exclusive supplier to Ather Energy. 3% of total revenue comes from Ather but its significant as Alicon’s content per 2W vehicle goes to 17 kg in EV from 2-3 kg in ICE.

Orderbook stands at 3250 cr, including orders worth Rs 810 cr from JLR Daimler, Samsung and MAHLE, Rs 1,100 cr from PSA, Toyota, and Renault, ~Rs 900 cr from Mahindra, Dana, Reml, Eaton, Rs 150 cr from TACO. Orderbook has 33% EV orders in last 9 months and 57% in Q3FY22.

🔍CAPEX plans: ACL plans to carry out capex of about Rs 267 crore during FY22-24, which is expected to be funded largely by equity and internal accrual and marginally through debt. With net asset turn of 3x, this may translate into additional 800 cr revenue.

90 cr capex scheduled for FY22 was deferred due to uncertain macro environment and 55-60 cr out of it was deployed to value added finishing and machining processes.

🔍Key Risks:

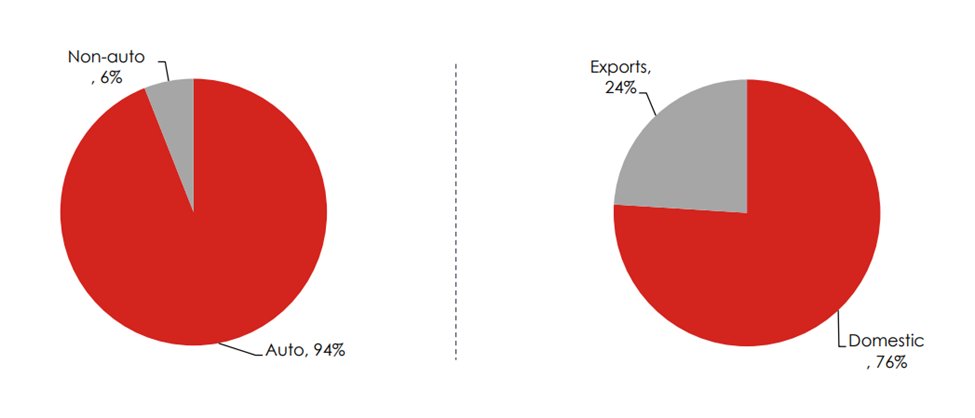

1) 94% revenue comes from Auto industry at the moment and cylinder head is their flagship product. E-mobility is a threat to ACL’s key product as cylinder heads are not required in EVs.

1) 94% revenue comes from Auto industry at the moment and cylinder head is their flagship product. E-mobility is a threat to ACL’s key product as cylinder heads are not required in EVs.

Though E-mobility vehicles are expected to be 30-35% of the total lot by 2030 and co has been developing new products rapidly.

2) Al penetration in 2W industry is already very high. ACL is trying to cut 2W contribution down to 25% by FY25.

3) Working capital intensive business.

2) Al penetration in 2W industry is already very high. ACL is trying to cut 2W contribution down to 25% by FY25.

3) Working capital intensive business.

Loading suggestions...