Let's start with the company' business first, what does the company actually do.

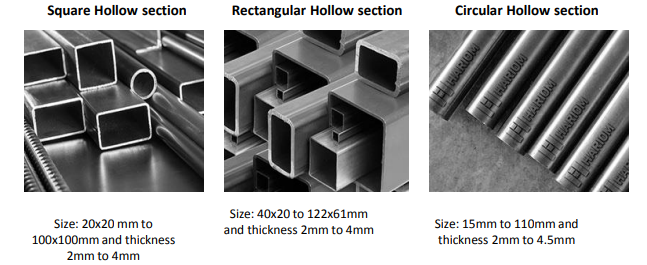

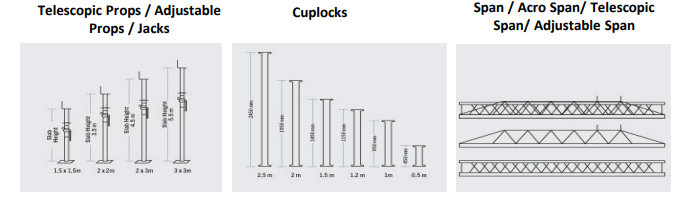

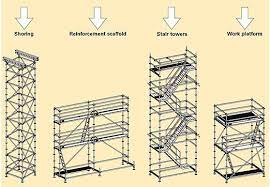

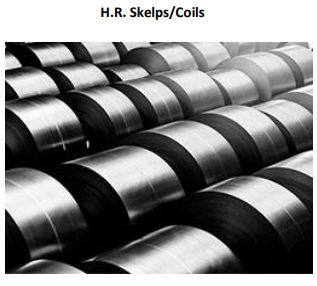

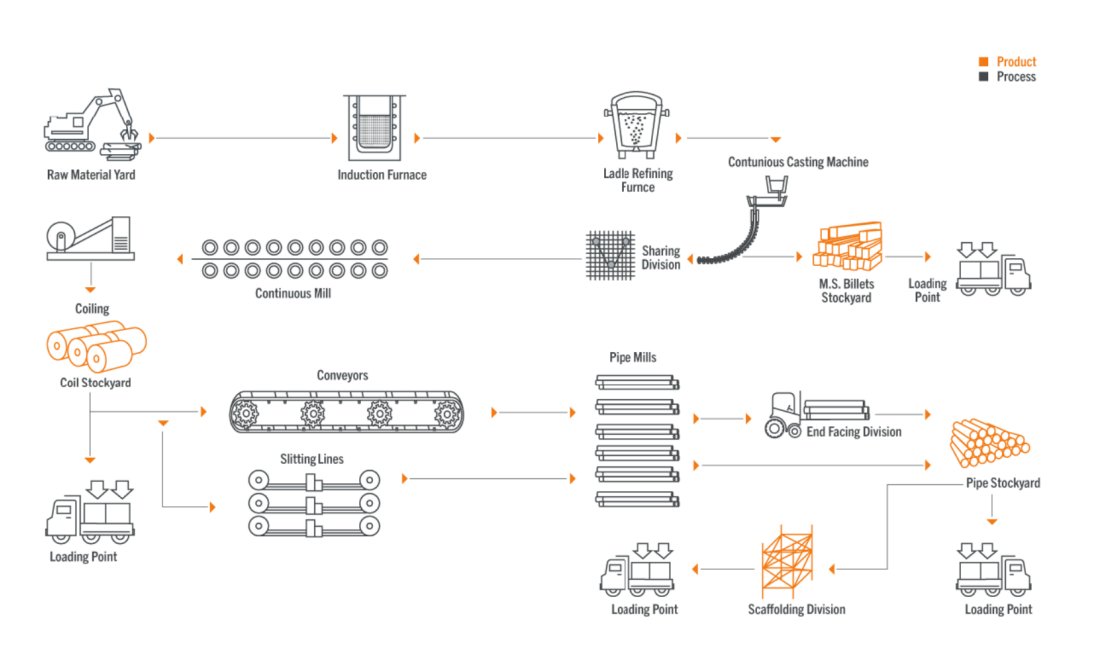

So HARI OM INDUSTRIES founded in 2007 is an integrated n integrated manufacturer of Mild Steel (MS) Pipes, Scaffolding, HR Strips, MS Billets, and Sponge Iron.

So HARI OM INDUSTRIES founded in 2007 is an integrated n integrated manufacturer of Mild Steel (MS) Pipes, Scaffolding, HR Strips, MS Billets, and Sponge Iron.

4. MILD STEEL BILLETS - The freshly made steel, which is still in the form of a metal bar or rectangle, is called billets.

MS Billets is a key input for rolling mill to product HR trips. These are used to make round bar, flat bar, angle plate, spring steel, wire rod etc.

MS Billets is a key input for rolling mill to product HR trips. These are used to make round bar, flat bar, angle plate, spring steel, wire rod etc.

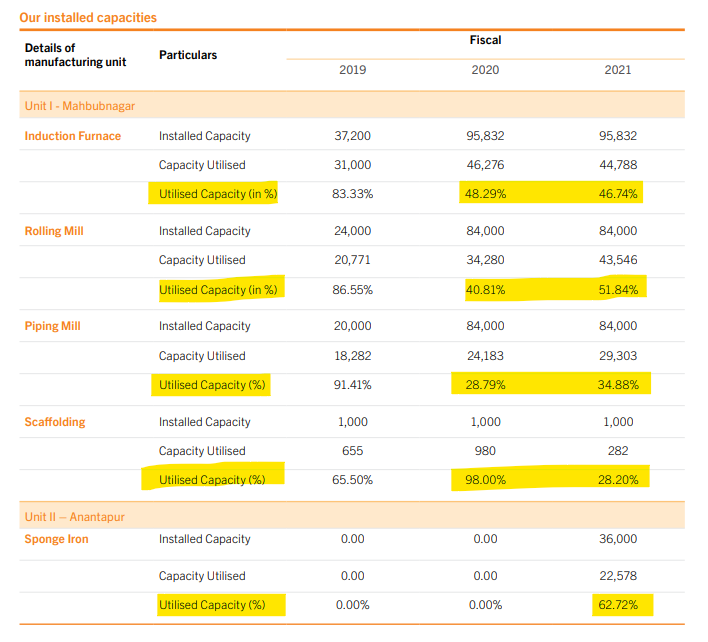

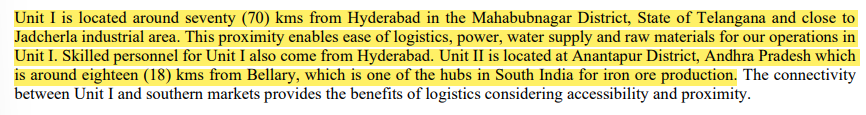

The company has two manufacturing units - One at Mahbubnagar, Telangana for Rolling mills, scaffolding, piping mill, Induction Furnace etc.

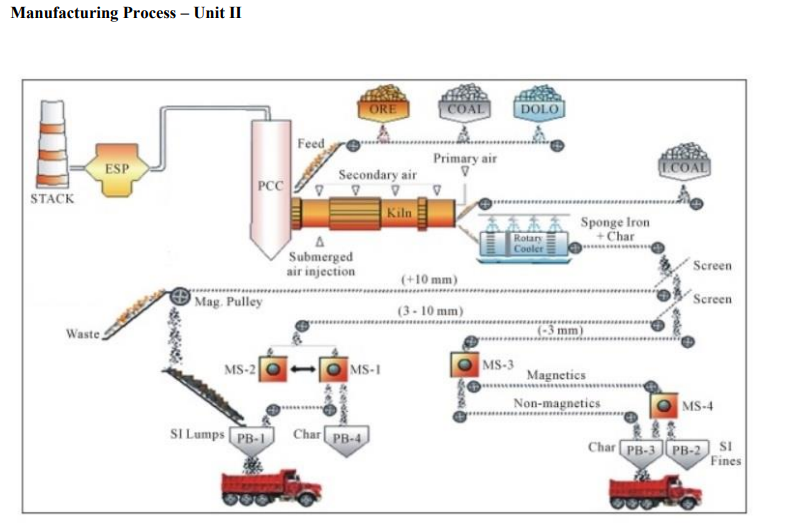

And 2nd Plant at Anantapur, AP for Sponge Iron which they recently acquired.

And 2nd Plant at Anantapur, AP for Sponge Iron which they recently acquired.

What makes them special is that they have integrated operations.

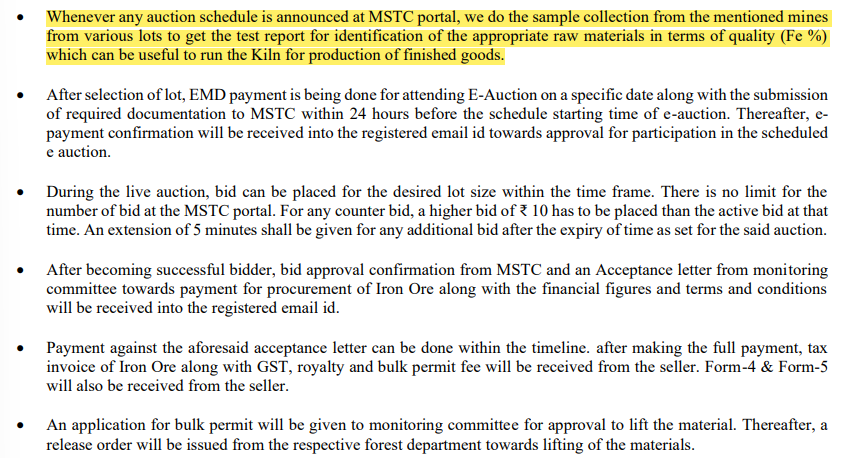

They themselves produce Sponge Iron from Iron Ore which is used to make final products like MS Pipes, Scaffoldings etc.

For example, MS Billets can be sold independently or maybe used as input for rolling mills.

They themselves produce Sponge Iron from Iron Ore which is used to make final products like MS Pipes, Scaffoldings etc.

For example, MS Billets can be sold independently or maybe used as input for rolling mills.

The company is eligible for obtaining private power from IEX thorough online bidding process in case of shortage.

They have installed pollution control equipment at their smoke emanating chimney that collects the dust particles which are then sold to cement companies.

They have installed pollution control equipment at their smoke emanating chimney that collects the dust particles which are then sold to cement companies.

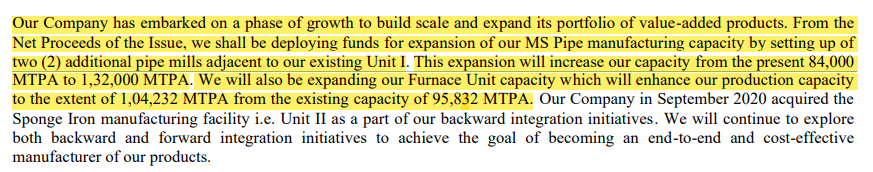

The company is expanding their product portfolio and adding more "value-added products" like - Rust Free MS Pipes, End Facing of MS Pipes, Packaging.

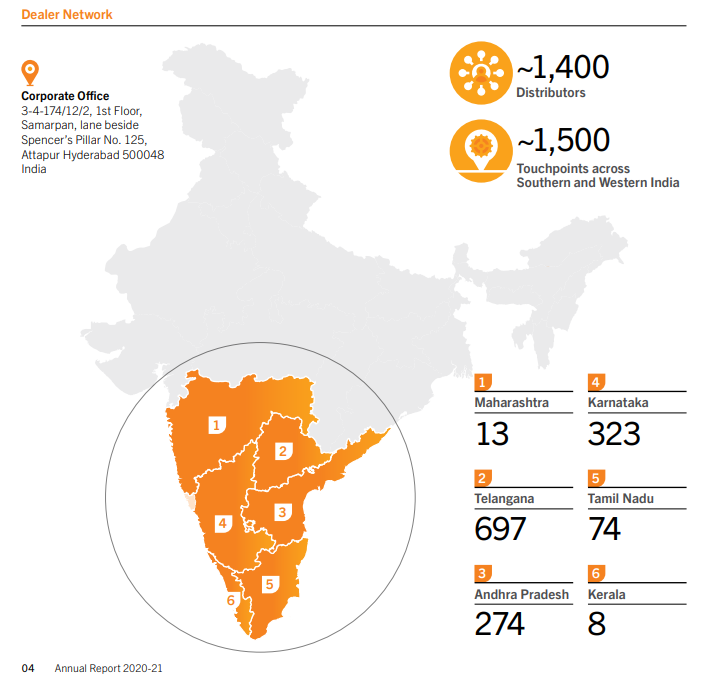

High geographical concentration - Telangana 41%, Karnataka 25%, Tamil Nadu 20%, Andhra 10%,

balance to Maharashtra, Pondicherry, Goa, Kerala, Punjab, etc.

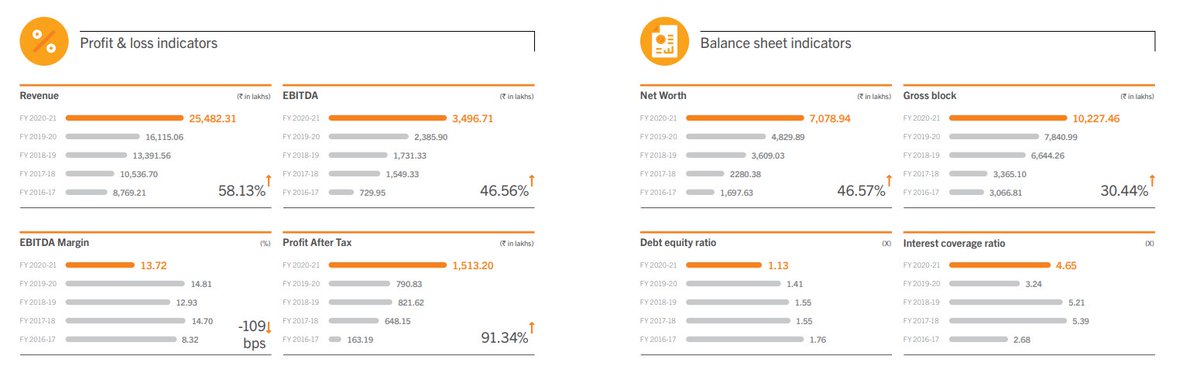

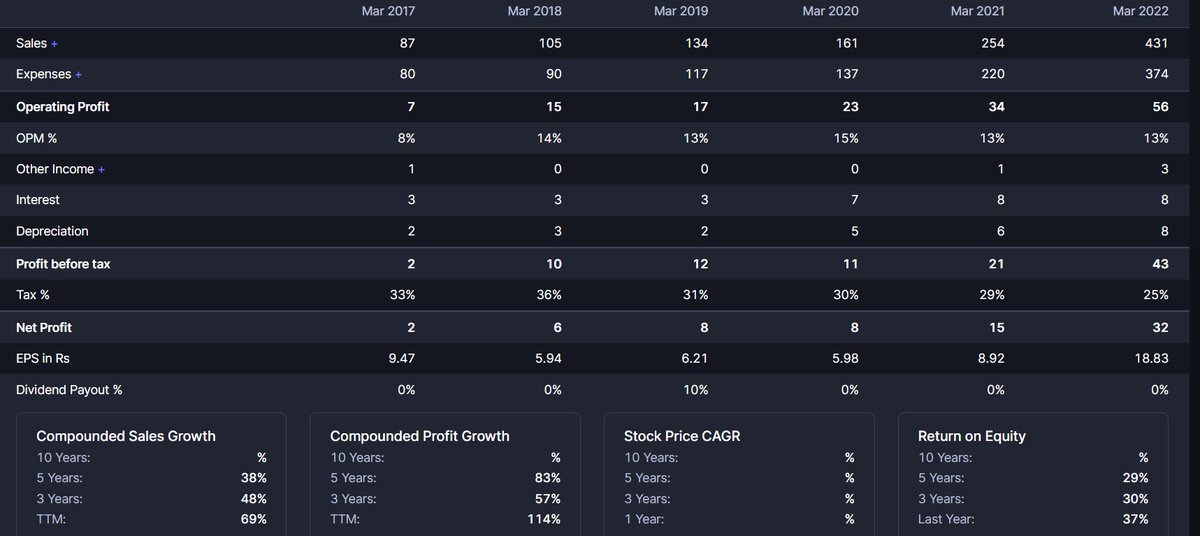

EBIDTA per ton is around 8000 - 8500rs

balance to Maharashtra, Pondicherry, Goa, Kerala, Punjab, etc.

EBIDTA per ton is around 8000 - 8500rs

Have already discussed the negative points.

It's a risky business as it is a commodity business which is cyclical in nature.

It's a risky business as it is a commodity business which is cyclical in nature.

Don't forget to like, share and re-tweet

@soicfinance @ishmohit1 @sahil_vi @suru27 @badola_arjun @shubhfin @shivang_ran @abhymurarka

Re-tweet the 1st tweet -

@soicfinance @ishmohit1 @sahil_vi @suru27 @badola_arjun @shubhfin @shivang_ran @abhymurarka

Re-tweet the 1st tweet -

Loading suggestions...