👣Footprint

GESL entered into business in 1987. Over the years they've emerged as one of the leading rPET Fibre manufacturers in India. We pioneered the manufacture of rPET Fibre and rPET Yarn from pre & post-consumer PET Bottle scrap.

GESL entered into business in 1987. Over the years they've emerged as one of the leading rPET Fibre manufacturers in India. We pioneered the manufacture of rPET Fibre and rPET Yarn from pre & post-consumer PET Bottle scrap.

🎓Founder

Shri Shyam Sunder Sharmma, the founder of GESL, aged 72 years, is a post-graduate in commerce. He is a first-generation entrepreneur and textile technocrat having management experience of over 51 years including 25 years with various Birla Group in senior positions.

Shri Shyam Sunder Sharmma, the founder of GESL, aged 72 years, is a post-graduate in commerce. He is a first-generation entrepreneur and textile technocrat having management experience of over 51 years including 25 years with various Birla Group in senior positions.

⭐️Star of the show

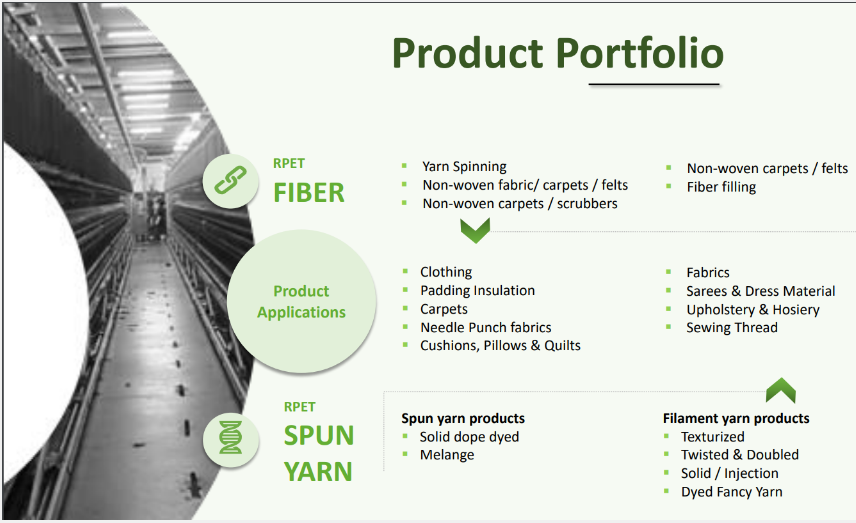

They're into manufacturing rPET Fibre & rPET Yarn from PET plastic scrap in India. They collect and recycle PET bottles through our pan-India network of scrap dealers and contractors, who in turn work through rag pickers for supplying PET plastic waste to us.

They're into manufacturing rPET Fibre & rPET Yarn from PET plastic scrap in India. They collect and recycle PET bottles through our pan-India network of scrap dealers and contractors, who in turn work through rag pickers for supplying PET plastic waste to us.

💼Use case

Driven by the aim of turning waste into wealth, they innovate & producing value-added RPSF that find application in the manufacture of textiles (T-Shirts, body warmers), functional textiles (non-woven air filter fabric, geotextiles, carpets) & fillings (pillows, toys)

Driven by the aim of turning waste into wealth, they innovate & producing value-added RPSF that find application in the manufacture of textiles (T-Shirts, body warmers), functional textiles (non-woven air filter fabric, geotextiles, carpets) & fillings (pillows, toys)

🏭Current capacity -

They have manufacturing units in Kanpur, Rudrapur, and Bilaspur.

Ganesha has a cumulative capacity of 1,18,800 TPA (1.08,600 TPA of RPSF, 7200 TPA of RPSY3000 TPA of Dyed and Texturised/ Twisted Filament Yarn) of rPET Fibre and yarn.

They have manufacturing units in Kanpur, Rudrapur, and Bilaspur.

Ganesha has a cumulative capacity of 1,18,800 TPA (1.08,600 TPA of RPSF, 7200 TPA of RPSY3000 TPA of Dyed and Texturised/ Twisted Filament Yarn) of rPET Fibre and yarn.

♻️Recycling Process :

(i) They recycle discarded PET bottles into user-friendly polyester staple fibre and polyester spun yarn having versatile applications.

(i) They recycle discarded PET bottles into user-friendly polyester staple fibre and polyester spun yarn having versatile applications.

(ii) To source raw material (Pet plastic waste) they have developed a pan India network of scrap dealers and contractors who in turn work through rag pickers for supplying the PET plastic waste to the Company.

(iii) PET plastic waste is being crushed and baled at collection centers and received in their manufacturing facilities and sent to factories for further processing. The network enables them to collect about 350 tons of PET plastic waste daily.

3 Pillars of Strength

👉State-of-the-art Technology -

The products will be produced with the best-in-class recycling technology, customized for Indian waste. Go Rewise’s products are USFDA & EFSA approved and safe for food-grade packaging.

👉State-of-the-art Technology -

The products will be produced with the best-in-class recycling technology, customized for Indian waste. Go Rewise’s products are USFDA & EFSA approved and safe for food-grade packaging.

👉Sustainability Supremacy -

Besides being a zero liquid discharge facility, Go Rewise aims to go an extra mile through maximum use of renewable energy & minimum water consumption.

👉Unmatched Legacy -

Go ReWise is manned by industry experts with decades of industry experience.

Besides being a zero liquid discharge facility, Go Rewise aims to go an extra mile through maximum use of renewable energy & minimum water consumption.

👉Unmatched Legacy -

Go ReWise is manned by industry experts with decades of industry experience.

💡Industry Dynamics

They are very bullish about the future of the recycling industry not only in India but globally.

Recycling will always remain their core focus area and all future expansions would primarily be in that direction only.

They are very bullish about the future of the recycling industry not only in India but globally.

Recycling will always remain their core focus area and all future expansions would primarily be in that direction only.

Warangal Plant Update -

(a) They have started the commissioning of the Chips plant and have started production. Fibre and FDY plants are progressing well and expected to start by September.

(b) They spent 300Cr by March'22 in that facility another 125Cr would be spent.

(a) They have started the commissioning of the Chips plant and have started production. Fibre and FDY plants are progressing well and expected to start by September.

(b) They spent 300Cr by March'22 in that facility another 125Cr would be spent.

(c) The technology they have installed in the Warangal plant is already USFDA-approved & US FDA has already given the mandate for that technology.

(d) Plant was affected due to the lockdown and they're facing big issues in terms of the timely availability of electronic parts.

(d) Plant was affected due to the lockdown and they're facing big issues in terms of the timely availability of electronic parts.

Nepal Plant Update -

(a)They started the washline and commenced production. This project is expected to operate at full capacity by Sept'22. They plan to use this capacity for captive consumption unless we have a better opportunity in the export market.

(a)They started the washline and commenced production. This project is expected to operate at full capacity by Sept'22. They plan to use this capacity for captive consumption unless we have a better opportunity in the export market.

(b They are getting the raw material cheaper by about 15% in Nepal so that is actually the cost-benefit available to us in that facility. This gives an opportunity for higher sustainable margins also.

HDPE Pilot Plant -

(a) They're going to start recycling rigid plastics(Kanpur).

To seize upcoming opportunities where demand would be emanating for quality products in recycled rigid plastic (HDPE, PP, etc.) segment to fulfill the EPR liability of brand owners & manufacturers.

(a) They're going to start recycling rigid plastics(Kanpur).

To seize upcoming opportunities where demand would be emanating for quality products in recycled rigid plastic (HDPE, PP, etc.) segment to fulfill the EPR liability of brand owners & manufacturers.

(b) The capacity of this plant is 300 tons per month. Post successful implementation, they would ramp up the capacity to 1,000 tons per month during FY2022.

(c) The estimated project cost would be around Rs 30 crore (funded through insurance claim proceeds)

(c) The estimated project cost would be around Rs 30 crore (funded through insurance claim proceeds)

☸️Spin Unit for Yarn

(i) RPSF manufactured in Rudrapur is categorized as medium tenacity fibre & those manufactured in Bilaspur facility (to be manufactured in Warangal) are called high tenacity fibre. Given price-cost matrix, medium tenacity fibres may not sustain the margins.

(i) RPSF manufactured in Rudrapur is categorized as medium tenacity fibre & those manufactured in Bilaspur facility (to be manufactured in Warangal) are called high tenacity fibre. Given price-cost matrix, medium tenacity fibres may not sustain the margins.

(ii) They are successfully running a spinning unit consuming 100% of our medium tenacity fiber & the unit is making good margins. They were also running a yarn spinning unit on job work which was contributing to a production of 1500-1800 annually.

(iii) So sensing the future as well as to increase our margins from medium tenacity fiber segment, they've consciously decided to put up a spinning unit with a capacity of 34,000 spindles at Temra, adjacent to our existing unit.

(iv) It would be a green field project with an estimated project cost of Rs 230 crore and it would be implemented over a period of the next 18 months.

At optimum capacity utilization, the unit would be producing around 12,000 tons of yarn valuing about Rs. 250 crores.

At optimum capacity utilization, the unit would be producing around 12,000 tons of yarn valuing about Rs. 250 crores.

(v) They would be manufacturing mélange & doubled/ fancy yarn, using our medium tenacity fiber, with an est. EBITDA margins in the range of 25-30% with a target ROE of 18%. They'll be spending about 70-75 Crs in the yarn facility in FY2022 & the rest would be done in FY2024.

New Regulations -

1. Regulations have been introduced whereby all the brand owners & manufacturers are required to have 30% recycled contents in their plastic packaging from FY 2025-26, this limit would be extended by 10% every year till it reaches 60%, i.e. by FY 2028-29.

1. Regulations have been introduced whereby all the brand owners & manufacturers are required to have 30% recycled contents in their plastic packaging from FY 2025-26, this limit would be extended by 10% every year till it reaches 60%, i.e. by FY 2028-29.

2. EPR - Extended Producer Responsibility refers to responsibility of mgt of disposal.

The main objective is to develop an easy & effective system that takes care of the collection, segregation, transportation of the material to the waste disposal facility approved by MPCB/CPCB.

The main objective is to develop an easy & effective system that takes care of the collection, segregation, transportation of the material to the waste disposal facility approved by MPCB/CPCB.

🥳BROWNIE POINTS

👉They aim to move towards sustainable efficiency. They are well equipped to recycle 90% of the water required in our operations & only 10% fresh water would be needed. We are setting up an ETP plant that would be on the Zero liquid discharge principle.

👉They aim to move towards sustainable efficiency. They are well equipped to recycle 90% of the water required in our operations & only 10% fresh water would be needed. We are setting up an ETP plant that would be on the Zero liquid discharge principle.

👉They are having about 500 kinds of products in our basket which are available for every kind of application to the end consumer number one.

👉They are on the preferred vendor list of some brands for which they make products, so it is also a compulsion for them to buy from us.

👉They are on the preferred vendor list of some brands for which they make products, so it is also a compulsion for them to buy from us.

👉Recyclers will get more business due to EPR regulations also.

👉Go revise to be a symbolic pride for them

👉Go revise to be a symbolic pride for them

👉They are in process of being onboarded by global brands after clearing their social audits, already started to use the patented DNA technology of ADNAS, the USA in products, for the physical traceability of our fibre in final finished products.

📍Their end product is the benchmark against the virgin PSF which is a derivative of crude and the prices of crude make some impact on the prices of virgin PSF, so indirectly we are also impacted by the prices of crude.

Ganesha Ecosphere - The World of PET Recycling

youtu.be

youtu.be

🔹B2B CHIPS BUSINESS -

1. They are sensing that B2B chips business would be the most accelerated kind of product in the market out of all new and old products.

1. They are sensing that B2B chips business would be the most accelerated kind of product in the market out of all new and old products.

2. They've imported USFDA-approved machinery for this use of recycling in plastic pet packaging so that is why they went to Europe for this.

Bottle-to-bottle grade chips will be used by mixing this in the virgin pet chips for making again the bottles.

Bottle-to-bottle grade chips will be used by mixing this in the virgin pet chips for making again the bottles.

🌎Export Market

China's slow down has unfolded a good opportunity for us to penetrate the export market and they made an export sale of Rs. 128.32 crore during FY 2022 (Rs. 35.84 crore Q4FY22) which is a growth of 112% over Rs. 60.53 crore export sale during FY2021.

China's slow down has unfolded a good opportunity for us to penetrate the export market and they made an export sale of Rs. 128.32 crore during FY 2022 (Rs. 35.84 crore Q4FY22) which is a growth of 112% over Rs. 60.53 crore export sale during FY2021.

🔖Numbers ??

⚡️Though the EBITDA improved in absolute terms, margins declined in comparison to last year because of an increase in input costs as well as manufacturing costs, particularly power and fuel cost.

⚡️Though the EBITDA improved in absolute terms, margins declined in comparison to last year because of an increase in input costs as well as manufacturing costs, particularly power and fuel cost.

⚡️During Q1FY22, the company provided an exceptional loss of Rs 25.1 Cr due to a fire in the Kanpur Plant, which has been reversed in Q4FY22.

⚡️The contribution of export sales to total sales reached 12.5% from the earlier level of 7.5 -8%.

⚡️The contribution of export sales to total sales reached 12.5% from the earlier level of 7.5 -8%.

⚡️They're putting up another production line that is suitable for making recycled rigid plastic chips. So it will be a higher realization product than the current facility.

⚡️Rpsf getting Rs. 97-98/Kg which is against 110 to 115 of virgin PSF. The realizations have improved by about 25% in the last year though the cotton prices have increased multifold.

⚡️Warangal plant they are expecting 600 Crores topline from there maintaining this 25% margin.

⚡️Existing business doing 1000 Crores and new business is doing another 1000 Crores by FY2024 with far superior EBITDA margin.

⚡️Existing business doing 1000 Crores and new business is doing another 1000 Crores by FY2024 with far superior EBITDA margin.

⚡️Any new CAPEX which they are now targeting we are targeting only those projects which is having at least 18% - 20% ROE

⚡️HDPE At a full capacity of 1000 tons per month it would be around 90 Crores to 100 Crores. They're expecting HDPE would be a more than 20% EBITDA.

😍RIGID PLASTIC OPPORTUNITY

(i) There are several different products one is PET and one is rigid plastic from polyethylene, polypropylene.

In Kanpur and Warangal they're coming up with other rigid plastics than PET, so all HDPE, PP polypropylene.

(i) There are several different products one is PET and one is rigid plastic from polyethylene, polypropylene.

In Kanpur and Warangal they're coming up with other rigid plastics than PET, so all HDPE, PP polypropylene.

(ii) This is a big market where the rigid plastic consumption in India is about 10 times of what we are having of PET. This offers us a huge market.

📊Finacial Metrics

- ROCE 11.7 %

- ROE 11.4 %

- OPM 11.2 %

- Debt to equity 0.62

- Sales Growth 3 years : 36%

- Profit Growth 3 Years : 46%

- Promoter Holding : 42.3%

- ROCE 11.7 %

- ROE 11.4 %

- OPM 11.2 %

- Debt to equity 0.62

- Sales Growth 3 years : 36%

- Profit Growth 3 Years : 46%

- Promoter Holding : 42.3%

🧪Valuations

🔹Stock P/E : 15.7 (3-Year Median - 27.84)

🔹EV/EBITDA : 11.5 (3-Year Average: 12.03)

🔹Market Cap to Sales : 1.24

🔹Stock P/E : 15.7 (3-Year Median - 27.84)

🔹EV/EBITDA : 11.5 (3-Year Average: 12.03)

🔹Market Cap to Sales : 1.24

Disclaimer -

This research has been shared for educational purposes only. Do your own due diligence before investing.

All information has been taken from various investor-friendly websites, annual reports, etc.

Got a lot of information from the Valuepickr forum.

This research has been shared for educational purposes only. Do your own due diligence before investing.

All information has been taken from various investor-friendly websites, annual reports, etc.

Got a lot of information from the Valuepickr forum.

Loading suggestions...