👣Roots

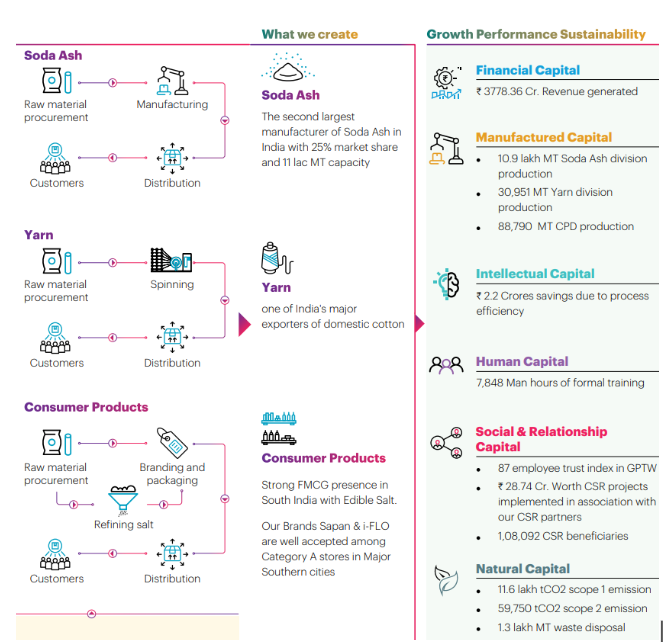

GHCL Limited was incorporated in 1983. It has ascertained its footprints in the Chemicals, Textiles, and Consumer Products segments.

GHCL Limited was incorporated in 1983. It has ascertained its footprints in the Chemicals, Textiles, and Consumer Products segments.

👁🗨Mission

GHCL is a leading producer of Soda Ash with an aim of becoming the country’s largest producer of Soda Ash within the next five years.

GHCL is a leading producer of Soda Ash with an aim of becoming the country’s largest producer of Soda Ash within the next five years.

🧑🎓Promotor

Mr.Sanjay Dalmia is the Non-executive Chairman (Promoter) of GHCL since its inception. He is an eminent Industrialist & Ex-member of Rajya Sabha. Under his guidance, Company has achieved new heights in terms of excellent growth in business and profitability.

Mr.Sanjay Dalmia is the Non-executive Chairman (Promoter) of GHCL since its inception. He is an eminent Industrialist & Ex-member of Rajya Sabha. Under his guidance, Company has achieved new heights in terms of excellent growth in business and profitability.

🏭Current Capacity

(i) They have a Soda Ash manufacturing plant at Sutrapada in Gujarat with an installed capacity of 11 Lakh MTPA and are in the process of expanding it by another 500 Thousand MTPA by end of 2025.

It contributes to 25% of the country’s annual domestic demand.

(i) They have a Soda Ash manufacturing plant at Sutrapada in Gujarat with an installed capacity of 11 Lakh MTPA and are in the process of expanding it by another 500 Thousand MTPA by end of 2025.

It contributes to 25% of the country’s annual domestic demand.

(ii) GHCL Soda Ash is available in two grades –light and dense grade and is marketed in India under the brand name ‘LION’. GHCL also has lignite mines at Khadsaliya in the Bhavnagar district of Gujarat to supply the raw material needed for the production of Soda ash.

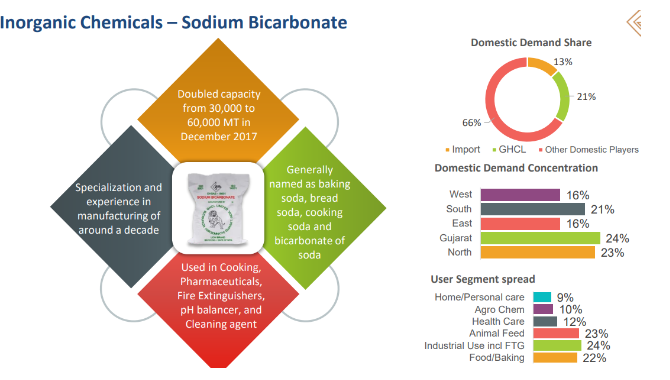

(iii) GHCL also produces around 65 Thousand MTPA of Sodium Bicarbonate which is an important raw material for industries like bakery, pharma, fire extinguisher manufacturing, cleaning agents, etc.

(iv) They also have Limestone mines at Sutrapada, Veraval, and Talala Taluka of Gir-Somnath district have an average production of 45 MT to 500 MT per day of chemical grade limestone.

I. GHCL SODA ASH BUSINESS

GHCL Limited is a leading producer of Soda Ash in India and the Soda Ash business contributes about 75.64% of the total standalone revenue of the Company.

GHCL Limited is a leading producer of Soda Ash in India and the Soda Ash business contributes about 75.64% of the total standalone revenue of the Company.

Light Soda Ash - It is an important basic industrial alkali chemical used in soap & detergents, pulp & paper, iron and steel, aluminum cleaning compounds, water softening and dyeing, fiber reactive dyes, effluent treatment, and production of chemicals.

Dense Soda Ash - It is used in Glass manufacturing (Flat Glass, Container Glass, Plate Glass, deep processing to other high-grade glass for example automotive glass, curtain wall glass), Silicate, Ultramarine, and other chemical industries.

✍️Marquee clients for Soda Ash export are -

HUL, HNG, Borosil Renewable Limited, FENA, P&G, Saint Gobain, Patanjali, Hindustan Zinc, Piramal, etc. With a powerful Soda Ash B2B & B2C supply chain, GHCL is determined to ensure best-in-class efficiency in Soda Ash Segment.

HUL, HNG, Borosil Renewable Limited, FENA, P&G, Saint Gobain, Patanjali, Hindustan Zinc, Piramal, etc. With a powerful Soda Ash B2B & B2C supply chain, GHCL is determined to ensure best-in-class efficiency in Soda Ash Segment.

The outbound logistics network of our Soda Ash business comprises one dispatch center and 17 warehouses spread across the country.

Demand -

In Q1, Soda Ash demand has remained good driven by the glass industry with additional demand coming from the solar glass and lithium carbonate user segment. There is no expected demand side issue apart from the detergent business.

In Q1, Soda Ash demand has remained good driven by the glass industry with additional demand coming from the solar glass and lithium carbonate user segment. There is no expected demand side issue apart from the detergent business.

Covid Impact - Post-pandemic the revival of dyes, intermediates, and specialty chemical industry has shown tremendous growth, the requirement of Soda Ash from these industries is good and is expected to continue throughout the year.

Global Tensions -

The impact of the Russia-Ukraine situation with rising inflation and global economic turmoil will also have an impact on the Indian market and will eventually affect the spending habit of consumers and may result in a drop some demand destruction.

The impact of the Russia-Ukraine situation with rising inflation and global economic turmoil will also have an impact on the Indian market and will eventually affect the spending habit of consumers and may result in a drop some demand destruction.

Supply -

Supply is constrained by several sectors such as high energy prices, disruption in the supply of natural gas to EU market, and the Russian Ukraine situation.

High energy and raw material prices and rising fuel prices are a great cause of concern.

Supply is constrained by several sectors such as high energy prices, disruption in the supply of natural gas to EU market, and the Russian Ukraine situation.

High energy and raw material prices and rising fuel prices are a great cause of concern.

Import - Imports into India remained low compared to the last few years and going forward we believe that this demand & supply scenario shall continue.

Imports of Soda Ash to India are expected to be on the lower side in 2022 and this will lead to more tightness in the market.

Imports of Soda Ash to India are expected to be on the lower side in 2022 and this will lead to more tightness in the market.

Current Dd/Ss Dynamics

They witnessed a solid demand trajectory in the key end-user categories combined with better realization gains. They undertook price hikes during the quarter to offset the rising cost pressure.

They remain optimistic about growth in Inorganic Chemicals.

They witnessed a solid demand trajectory in the key end-user categories combined with better realization gains. They undertook price hikes during the quarter to offset the rising cost pressure.

They remain optimistic about growth in Inorganic Chemicals.

II. GHCL's YARN DIVISION

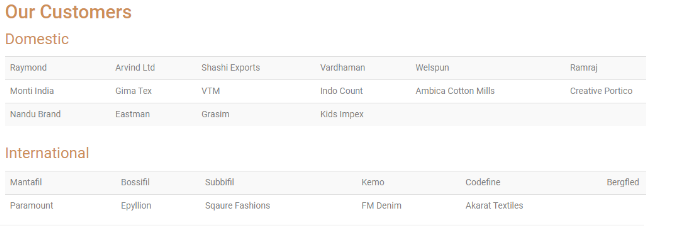

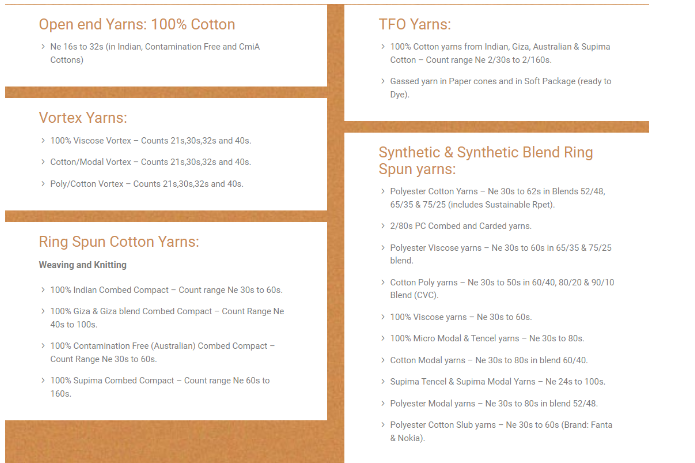

GHCL’s Yarn Division is one of the leading yarn manufacturers with 2 manufacturing units in Madurai and Manapara. The division has state-of-the-art machinery that produces high-quality Cotton & Synthetic yarn.

GHCL’s Yarn Division is one of the leading yarn manufacturers with 2 manufacturing units in Madurai and Manapara. The division has state-of-the-art machinery that produces high-quality Cotton & Synthetic yarn.

GHCL Meenakshi mills in Madurai is equipped with world-class machinery from Rieter, Trutzschler, LMW, KTTM, Suessen, Uster, Muratec, Saurer Schlafhorst, Savio, SSM, and Suessen, Uster, Muratec.

They're one of India's major exporters of cotton yarn.

They're one of India's major exporters of cotton yarn.

The yarn produced here caters to various leading apparel and textile brands like Raymond, Tessitura Monti, Soktas, H & M, C & A, etc.

The yarn is sold to various customers in domestic and exports and a significant quantity is used at GHCL’s weaving plant at Vapi.

The yarn is sold to various customers in domestic and exports and a significant quantity is used at GHCL’s weaving plant at Vapi.

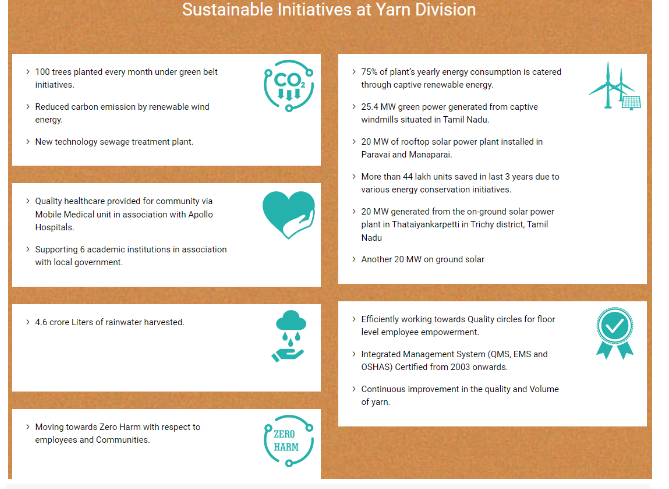

Company uses the 3R approach of Reduce, Reuse, and Recycle to maintain sustainable material management.

They have started using digital platforms to market our product which has helped them increase their customer base in existing markets like Italy, Germany, Bangladesh, etc.

They have started using digital platforms to market our product which has helped them increase their customer base in existing markets like Italy, Germany, Bangladesh, etc.

GHCL’s yarn spinning division is producing value-added yarn Viz. GIZA, SUPIMA, Australian, CmiA Yarn. Many specialized products are produced instead of tailor-made which will help to popularize the brand name through customer communication which includes True Trace technology.

Sustainability - The yarn division is using sustainable cotton to the extent of 50% during the current year and it is benchmarking to use around 90% sustainable cotton over a period.

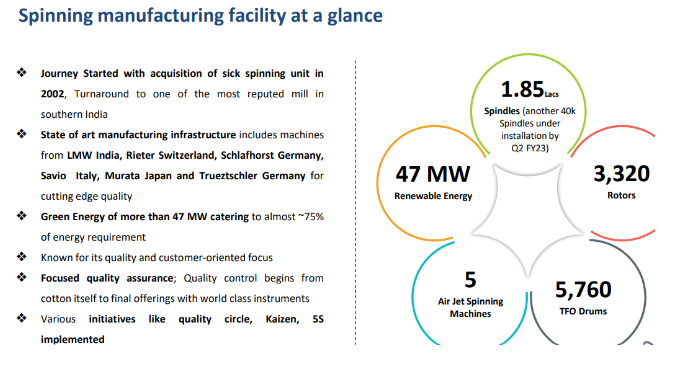

III. GHCL's SPINNING DIVISION

GHCL has spinning facilities located at Paravai in Madurai district and Manaparai in Trichy district, Tamil Nadu, India with a current production capacity of 85 MT per day.

GHCL has spinning facilities located at Paravai in Madurai district and Manaparai in Trichy district, Tamil Nadu, India with a current production capacity of 85 MT per day.

Operations of the Yarn division are based upon 4 pillars of our strategy i.e. innovation, traceability, sustainability, and giving back to society.

This has proven to be one of the most important differentiators for our products identified as the preferred ones in the market.

This has proven to be one of the most important differentiators for our products identified as the preferred ones in the market.

GHCL & Govt. of Tamil Nadu signed an MoU to invest 500 Crores to enhance the output of the state’s knitting and weaving sector.

GHCL would set up 40K ring spindles & 24 knitting machines to produce synthetic blended yarn & 100% cotton yarn for the knitting and weaving sectors.

GHCL would set up 40K ring spindles & 24 knitting machines to produce synthetic blended yarn & 100% cotton yarn for the knitting and weaving sectors.

GHCL yarn manufacturing facilities have 1.85 Lakh ring spindles, 3320 rotors, 5760 TFO spindles & 5 Airjet Spinning in Madurai & Tiruchirapalli District, Tamil Nadu.

Mission on sustainability reaches new heights with “Earthology” - Eco Cotton, Eco Corn Cotton & Eden Dyes.

Mission on sustainability reaches new heights with “Earthology” - Eco Cotton, Eco Corn Cotton & Eden Dyes.

Weavestry - the “best of all sheets” is made with a balanced hybrid weave and selected cotton fibers that are carefully woven and processed to perform at their best.

GHCL Yarn Division has reduced the receivables and stock of finished goods significantly and highly penetrated into the value-added and premium segments. Export of goods sizably increased from 5% level to 15% level and it will further grow in the coming financial year.

Cotton and Yarn prices remained elevated during the quarter which is now gradually getting normalized. Their focus on value-added offerings is providing us the impetus to drive gains in the medium to long term.

GHCL’s CONSUMER PRODUCT DIVISION

Manufactures & sells Edible salt and Industrial grade salt under the brand i-FLO & Sapan.

The division has its salt manufacturing facility at Vedaranyam in Nagapattinam district, Tamil Nadu & a refinery at Chennai for edible salt manufacturing.

Manufactures & sells Edible salt and Industrial grade salt under the brand i-FLO & Sapan.

The division has its salt manufacturing facility at Vedaranyam in Nagapattinam district, Tamil Nadu & a refinery at Chennai for edible salt manufacturing.

About i-FLO

- The consumer product division at GHCL markets its products under the brand “i-FLO – The choice of a Healthy Family”

- i-FLO’s brand philosophy is to provide valuable benefits to consumers by giving them quality products coupled with a wonderful brand experience.

- The consumer product division at GHCL markets its products under the brand “i-FLO – The choice of a Healthy Family”

- i-FLO’s brand philosophy is to provide valuable benefits to consumers by giving them quality products coupled with a wonderful brand experience.

i-FLO boasts a range of salts that are pure, white, and free-flowing. i-FLO’s competitive edge is the cost advantage when it comes to normal salt and a differential advantage of a unique product in the premium pricing.

A major slice of business owes to its sales of Industrial grade salt. Salt production saw a major downfall during the last 3 years due to unseasonal rains as salt production entirely depends on climatic conditions.

Production was delayed due to extended monsoon mainly.

Production was delayed due to extended monsoon mainly.

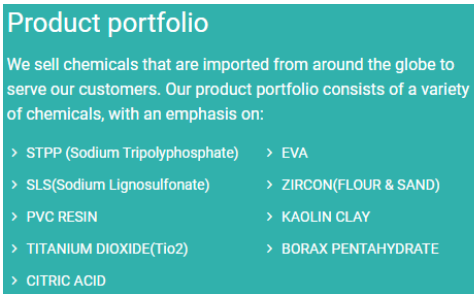

They are a one-stop shop for your chemical needs and maintain packaged and bulk inventory in warehouses across the country - ensuring prompt service of the products you need, when you need them.

Aim - provide the products you need – at right time, right place, & of right quality

Aim - provide the products you need – at right time, right place, & of right quality

Their supply & distribution network brings the advantages of a large company and the personalized attention from a local partner. They have a reliable supply chain and manufacturing partners which ensure that you'll be able to find the solutions you need.

⚡️KEY FOCUS AREAS -

a. We are focused on cost competitiveness, quality, and timely delivery of raw materials and products, with over 30 years of knowledge and expertise in logistics and supply chain.

a. We are focused on cost competitiveness, quality, and timely delivery of raw materials and products, with over 30 years of knowledge and expertise in logistics and supply chain.

b. For cost reductions, we have transitioned from coke to briquette coke and developed expertise in an appropriate mix of fuel.

c. GHCL has opted to install a pulverizer in the briquette plant for enhanced output.

c. GHCL has opted to install a pulverizer in the briquette plant for enhanced output.

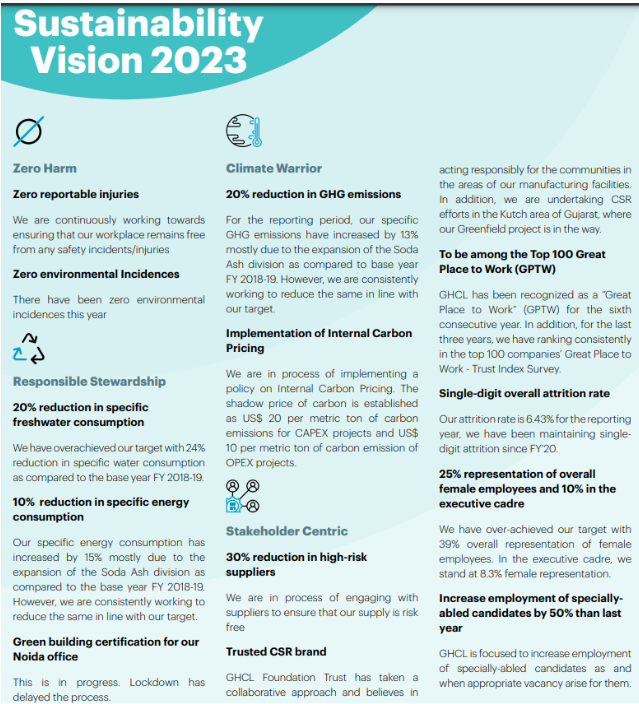

d. Augmenting our backward integration of raw material for enhanced control on the cost which focuses on reducing carbon footprint – proposed 6.5 MW of renewable energy project Inducting AI & IoT 4.0 for manufacturing excellence which can enable immense efficiencies.

e. Exploring product basket expansion – synergistic and value-added bulk chemicals.

f. Within each business they want to focus on digitization, customer centricity, and governance and sustainability measures.

f. Within each business they want to focus on digitization, customer centricity, and governance and sustainability measures.

g. Their investments in renewable energy and modernization and expansion of businesses will give them better leverage going forward.

h. GHCL is driven by the spirit of innovation and is continuously focusing on sustainable products and packaging innovations.

h. GHCL is driven by the spirit of innovation and is continuously focusing on sustainable products and packaging innovations.

i. They're implementing initiatives towards reducing consumption of natural resources.

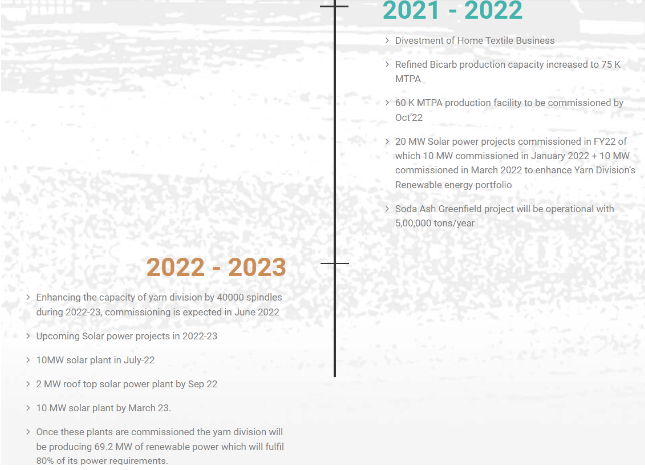

In Q4'21 commissioned two 10 MW solar power projects, to be followed by additional 20 MW Solar power project. Once done will be fulfilling 85% of energy requirement from renewable resources.

In Q4'21 commissioned two 10 MW solar power projects, to be followed by additional 20 MW Solar power project. Once done will be fulfilling 85% of energy requirement from renewable resources.

j. Traceability being a strong “pillar of practice” at GHCL, has led us to develop a ‘TRUE Trace’ platform based on QR code technology that has been fully implemented and audited by third-party accreditations.

For better understanding of the Soda Ash business must watch @ishmohit1 recent video on Tata chemicals.

youtube.com

youtube.com

📊De-Merger

In Jan, they decided to divest of the Home textiles business and demerge the Chemicals and Yarn businesses. Their focus continues to be on outperforming the competitors in core business of Chemicals and Yarn.

In Jan, they decided to divest of the Home textiles business and demerge the Chemicals and Yarn businesses. Their focus continues to be on outperforming the competitors in core business of Chemicals and Yarn.

Moving on to the de-merger of our textile business, we have received an order from honorable NCLT to conduct a meeting of unsecured creditors as well as shareholders on August 18, 2022.

With this positive development they shall be one step closer to completing the process by Q3

With this positive development they shall be one step closer to completing the process by Q3

Board approved a scheme of demerger where the Spinning business of GHCL will be demerged into GHCL Textiles Limited.

Shareholders of GHCL will be allotted shares in GHCL textiles Limited in the swap ratio of 1:1, one share of Rs. 2 each for every share of Rs. 10 held in GHCL.

Shareholders of GHCL will be allotted shares in GHCL textiles Limited in the swap ratio of 1:1, one share of Rs. 2 each for every share of Rs. 10 held in GHCL.

The resulting company will take over all the assets and liabilities of the Textile business and will be listed on NSE and BSE.

PS - No change in the shareholding pattern of the Demerged Company.

PS - No change in the shareholding pattern of the Demerged Company.

💪CAPEX PLANS

On the greenfield Capex :

They'll be in a position to start an activity, so from Jan-March'23, and hopefully, our target is March 2025 we should try to complete that because the longest duration was with this pipeline, which we have already awarded the contract.

On the greenfield Capex :

They'll be in a position to start an activity, so from Jan-March'23, and hopefully, our target is March 2025 we should try to complete that because the longest duration was with this pipeline, which we have already awarded the contract.

Marginal CAPEX :

It will be on the land acquisition, which they are acquiring, They have put around Rs.25 to Rs.30 Crores, but major Capex will only start from the middle of next year only (approx Rs.3500 Crores), the major significant outgo will be on the land.

It will be on the land acquisition, which they are acquiring, They have put around Rs.25 to Rs.30 Crores, but major Capex will only start from the middle of next year only (approx Rs.3500 Crores), the major significant outgo will be on the land.

🚩Risk Metrics -

1. Risks associated with the implementation of greenfield projects in the mid-term -

Healthy utilization of soda ash plant at its existing location where major capacity expansion is a constraint & expected good long-term growth prospects for domestic soda ash.

1. Risks associated with the implementation of greenfield projects in the mid-term -

Healthy utilization of soda ash plant at its existing location where major capacity expansion is a constraint & expected good long-term growth prospects for domestic soda ash.

2. CAPEX is expected to be implemented in a phased manner over the mid-term.

Any deviation in the size of its planned project and departure from the stated staggered implementation timeline could have an adverse impact on its leverage & debt coverage.

Any deviation in the size of its planned project and departure from the stated staggered implementation timeline could have an adverse impact on its leverage & debt coverage.

3. Price volatility -

The key raw materials & input costs of GHCL in the soda ash division pertain to salt, limestone, coal, lignite, freight, and power whereas in the yarn division, the same pertains to cotton and power.

Prices of all these inputs have elevated significantly.

The key raw materials & input costs of GHCL in the soda ash division pertain to salt, limestone, coal, lignite, freight, and power whereas in the yarn division, the same pertains to cotton and power.

Prices of all these inputs have elevated significantly.

How are they dealing with price volatility?

GHCL has undertaken price increases in soda ash which are expected to largely recover its higher costs in the soda-ash division whereas the spread b/w yarn & cotton have moderated which can result in a moderation in profitability.

GHCL has undertaken price increases in soda ash which are expected to largely recover its higher costs in the soda-ash division whereas the spread b/w yarn & cotton have moderated which can result in a moderation in profitability.

4. Cyclicality associated with the textile industry & exchange rate fluctuations -

Textile is an inherently cyclical industry & closely follows macroeconomic business cycles.

High competitive intensity in the textiles & volatility in cotton prices as well as foreign exchange.

Textile is an inherently cyclical industry & closely follows macroeconomic business cycles.

High competitive intensity in the textiles & volatility in cotton prices as well as foreign exchange.

📊Metric check:

ROCE : 25.9 %

ROE : 23.3 %

OPM : 28.0 %

Debt to equity : 0.26

Sales growth 5 Years : 6.30 %

Profit Var 5 Yrs : 11.2 %

Promoter holding : 19.0 % (1.1% pledged)

ROCE : 25.9 %

ROE : 23.3 %

OPM : 28.0 %

Debt to equity : 0.26

Sales growth 5 Years : 6.30 %

Profit Var 5 Yrs : 11.2 %

Promoter holding : 19.0 % (1.1% pledged)

🧪Valuation Ratios -

P/E Current : 6.88

5 Year Median : 6.81

P/B Current : 1.8

5 Year Average : 1.31

EV/EBIDTA Current: 5.19

5 Year Average : 5.16

Market Cap to Sales : 1.38

Management aims at getting net debt free by max next year end.

P/E Current : 6.88

5 Year Median : 6.81

P/B Current : 1.8

5 Year Average : 1.31

EV/EBIDTA Current: 5.19

5 Year Average : 5.16

Market Cap to Sales : 1.38

Management aims at getting net debt free by max next year end.

Disclaimer -

I have shared this information for educational purposes only. This is my personal understanding of the business.

Do your own due diligence before investing.

Information is sourced from the company website, various other investor forums, etc.

♻️RT for max reach

I have shared this information for educational purposes only. This is my personal understanding of the business.

Do your own due diligence before investing.

Information is sourced from the company website, various other investor forums, etc.

♻️RT for max reach

Loading suggestions...