The company is getting 58% of its total revenues from Exports as of FY22 out of which around 70% is contributed by Europe

The company has successfully developed the production of methyl salicylate using flow chemistry. It has successfully erected the flow reactor at Jhagadia

The company has successfully developed the production of methyl salicylate using flow chemistry. It has successfully erected the flow reactor at Jhagadia

which is expected to start production in Q3FY23.This will lead to a cost saving of 5-7%.For the company, Methyl salicylate generates 30% of their total revenues in the Specialty chemical business and 5% of the total revenue of the company. The company expects methyl salicylate to

The company is planning to commercialize 4 big existing products on their flow technology in the second half of FY23

The company has received trial orders for an agrochemical intermediate which is an import substitute products. This intermediate will be used to make a fungicide

The company has received trial orders for an agrochemical intermediate which is an import substitute products. This intermediate will be used to make a fungicide

agro active ingredient. The company will make only the intermediate which is needed to make this active ingredient. The company is not planning to manufacture active ingredients on the agro side. It is a validation batch of around 500 kg. The company expects to commercialize this

product by Q3FY23

The company has also received trial orders for a pharmaceutical intermediate which is also an import substitute product from a European client. It is a validation batch of around 5 tons. The company expects to commercialize this product by Q3FY23. The peak

The company has also received trial orders for a pharmaceutical intermediate which is also an import substitute product from a European client. It is a validation batch of around 5 tons. The company expects to commercialize this product by Q3FY23. The peak

of this product in the first half of CY23

The prices of Vinylene carbonate(VC) are going up due to the rise in raw material prices and increase in demand. The product is a low-value product and technology is very important to make this product. The company developed a process

The prices of Vinylene carbonate(VC) are going up due to the rise in raw material prices and increase in demand. The product is a low-value product and technology is very important to make this product. The company developed a process

additives based on the geography and applications

The company makes both FEC and VC which are used as additives in the electrolyte solution which goes into Li ion batteries. The company has sent its samples to various customers and within 1 year time, the company was able to get

The company makes both FEC and VC which are used as additives in the electrolyte solution which goes into Li ion batteries. The company has sent its samples to various customers and within 1 year time, the company was able to get

one customer for commercial trial demand. As per a report, the global market size for electrolyte additives is $1.2 billion. The company has been vocal about the fact that they will be manufacturing only the electrolyte additives and not the electrolyte salt. The company has

received orders from Gujarat Fluorochemicals and Neogen Chemicals which are making the electrolyte salt. The company first got this opportunity from their international partner in Israel and they have a 1-1.2 years of history in this electrolyte molecule. The technology to make

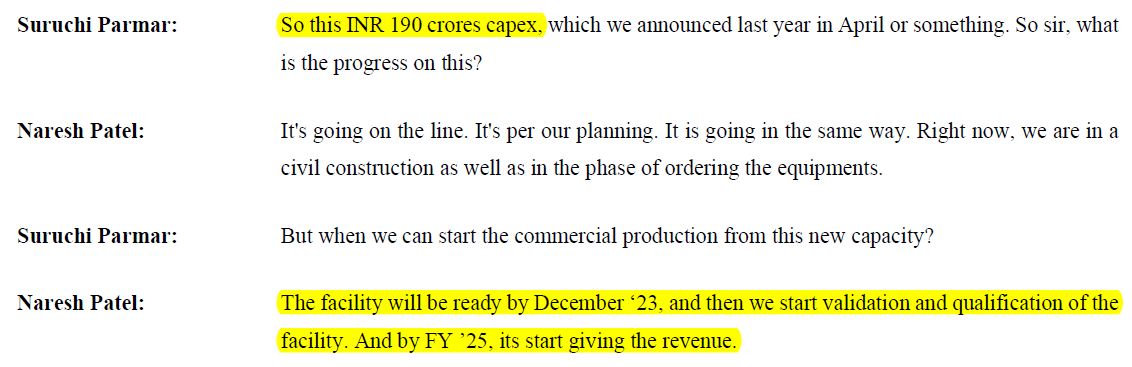

The company has done a capex of Rs 190 crores in Ankleshwar for making advanced pharmaceutical intermediates to support future business growth. The capex will be funded through a mix of IPO proceeds, internal accruals and debt which is a short-term working capital loan.

The company has got the environmental clearance for setting up this new facility which will have around 90 reactors which will be flow continuous reactors taking the total reactor capacity to 436 KL. This plant is expected to begin commercial production in Q4FY24 which is

Loading suggestions...