1. Company Overview

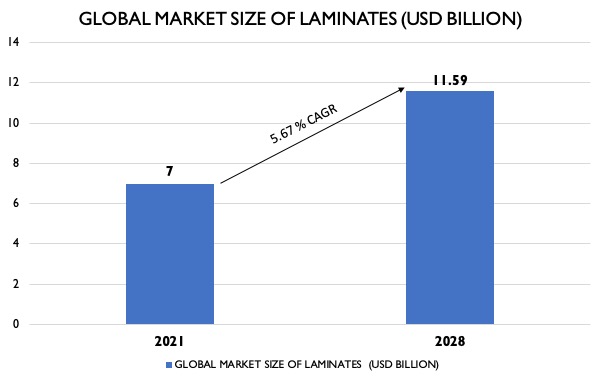

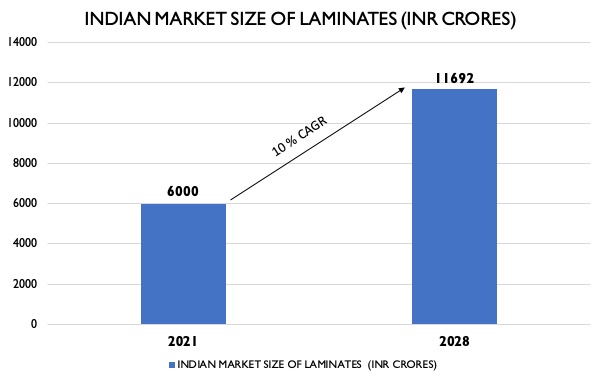

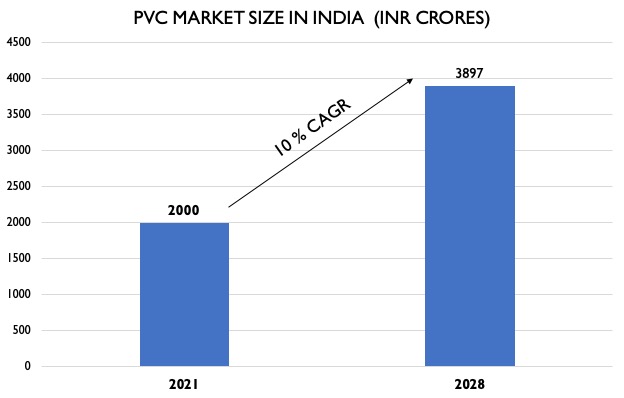

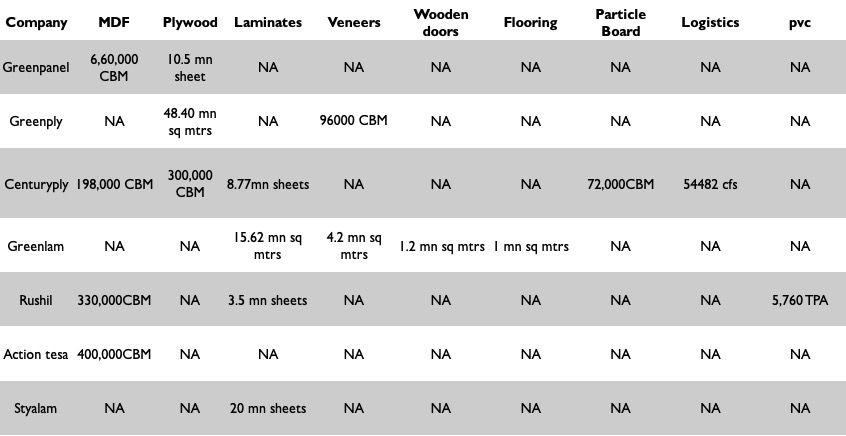

-Rushil Decor Limited was incorporated in 1993 and has been in this industry for over 30 years and currently having the fourth generation involved in the business. The business is divided into three segments mainly laminates, MDF and PVC. Rushil is one of the

-Rushil Decor Limited was incorporated in 1993 and has been in this industry for over 30 years and currently having the fourth generation involved in the business. The business is divided into three segments mainly laminates, MDF and PVC. Rushil is one of the

largest players in the laminate industry and third largest manufacturer of MDF boards.

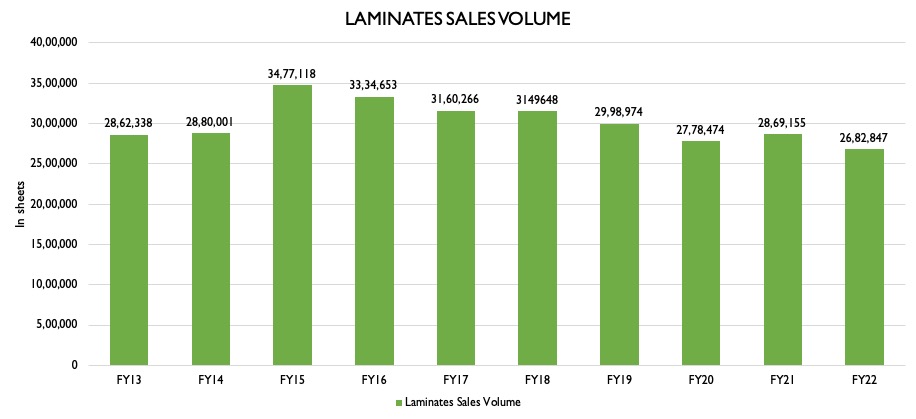

-In the laminates segment, they manufacture single sided decorative as well as double sided industrial laminates with a wide range of designs, colours and finishing spread across 3

-In the laminates segment, they manufacture single sided decorative as well as double sided industrial laminates with a wide range of designs, colours and finishing spread across 3

manufacturing plants located at Gujarat with capacity of 34.92 lakh sheets per annum.

-Coming to the MDF boards, they manufacture thin and thick boards and prelam boards with thickness ranging from 2mm to 30mm. Manufacturing facility for MDF board is at Chikmagalur, Karnataka

-Coming to the MDF boards, they manufacture thin and thick boards and prelam boards with thickness ranging from 2mm to 30mm. Manufacturing facility for MDF board is at Chikmagalur, Karnataka

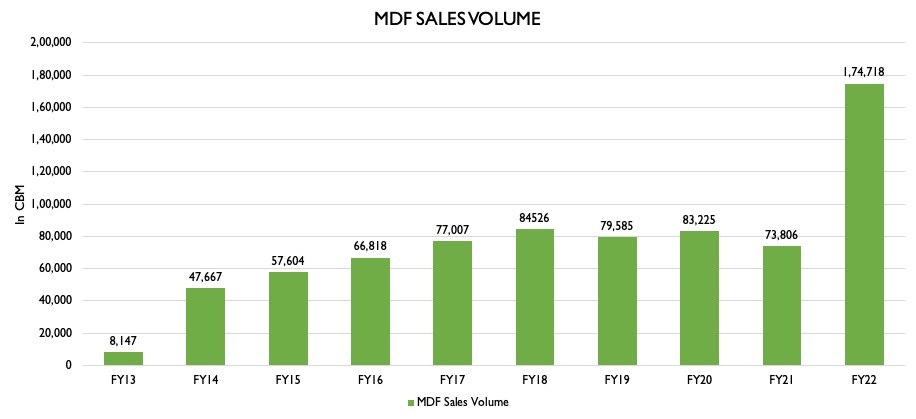

with capacity of 300 cubic metre per day or 90,000 cubic metre per annum. Recently a second and new manufacturing facility for MDF has commenced its operations from March 2021 at Visakhapatnam, Andhra Pradesh. Having installed capacity of 800 cubic metres per day or 2,40,000

cubic metres per annum, this new facility has added a strategic location advantage as it is set up in Southern India which is one of the prominent markets for MDF and closer to southern parts making it easier to facilitate exports. Rushil Decor also produces PVC with a capacity

of 12,480 cubic metres per annum.

2. Industry Overview

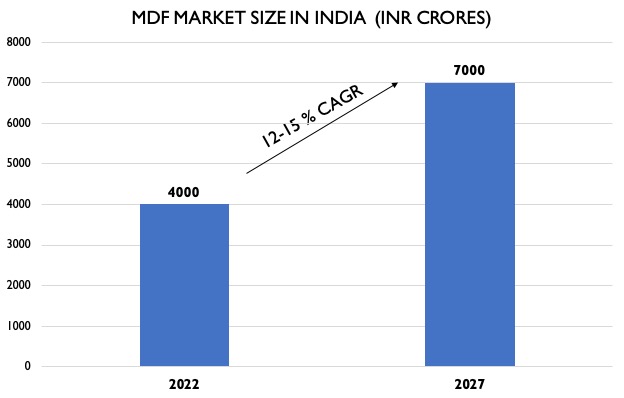

The wood panel industry includes plywood sheets, engineered wood panels (MDF [Medium Density Fibreboards] furniture board and particle board) and decorative surface products such as laminates. In 2022, the Indian wood

2. Industry Overview

The wood panel industry includes plywood sheets, engineered wood panels (MDF [Medium Density Fibreboards] furniture board and particle board) and decorative surface products such as laminates. In 2022, the Indian wood

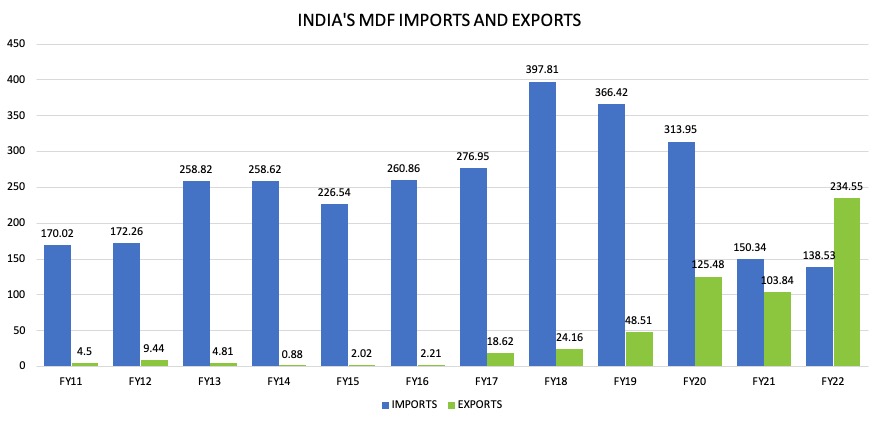

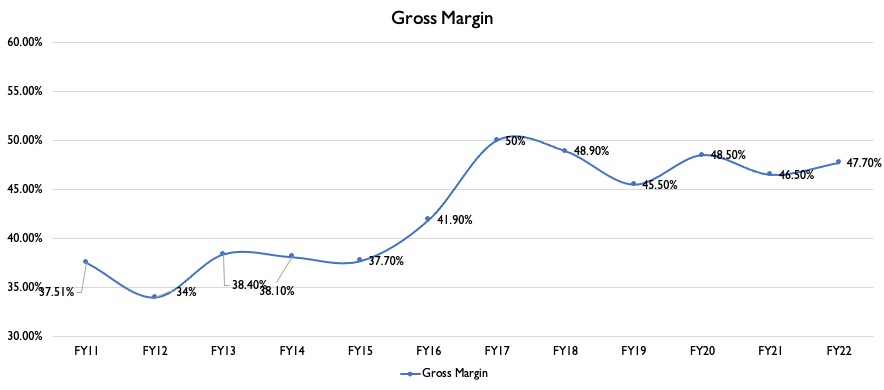

were around INR 18.62 Cr and INR 48.51 Cr. In this chart we can see that historically imports are more than the exports and after FY16 we can see huge imports entering in the Indian MDF market which affected the the domestic organised MDF manufacturers but between 2017 and 2019

the market size for MDF in India went up from INR 2,000 Cr to INR 3,200 Cr at peak utilisation because of increasing market size the organised players somehow managed to maintain their revenues but their margins got affected.

because of the increase in market size of MDF. Even some players like Greenply, CenturyPly, Action Tesa having capacities of manufacturing MDF but still they also came up with new capacities resulting in an increased competition in the domestic market. Increased capacities

together with increased imports led to a decrease in the realisation of MDF. This resulted in a fall in MDF prices from about INR 25,000 per cubic metres to around INR 19,000 per cubic metres and these factors also impacted the margins of Rushil Decor and some other players.

President (General). He was actively involved in the implementation of Andhra Pradesh Thin & Thick MDF project. He has a wide experience of around 9 years in the Laminate Industry, MDF Board Industry, Laminated Flooring Industry etc.

synthetic resin and wax. VIR MDF, from the house of Rushil Décor, is a new age product, a great alternative to solid wood, particle board and plywood. It is a favourite of OEM's, and conventional wood furniture manufacturers across the world.. VIR MDF lends itself to perfect

industries like electrical, electronics, Furniture, automotive, construction, medical and packaging. A beautiful fusion of a solid top coat and a cellular core, VIR PVC Boards are water-proof, termite-proof and fire-retardant. They have a range of colours and assurance of

durability promises exclusive designs across applications spanning interiors, direct digital printing, modular furniture and more.

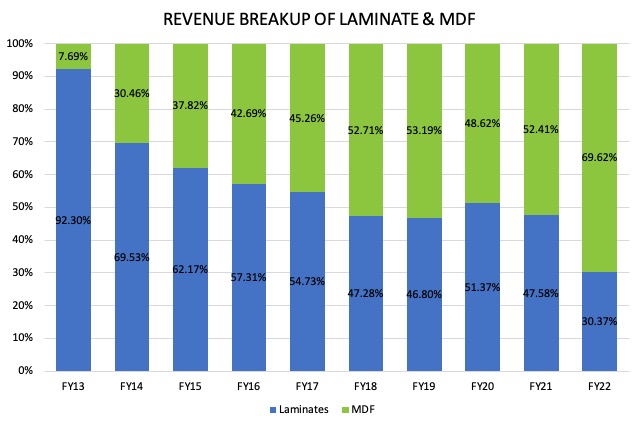

majority of revenue from MDF which is around 69.62% of total revenue and the rest is from the laminates segment.

8. Raw Materials For MDF

-Timber fibres- Lumber, also known as timber, is wood that has been processed into beams and planks, a stage in the process of wood

8. Raw Materials For MDF

-Timber fibres- Lumber, also known as timber, is wood that has been processed into beams and planks, a stage in the process of wood

production. Lumber is mainly used for construction framing, as well as finishing. Lumber has many uses beyond home building.

-Urea- Formaldehyde resin glue- Urea-formaldehyde, also known as urea-methanal, named for its common synthesis pathway and overall structure, is a

-Urea- Formaldehyde resin glue- Urea-formaldehyde, also known as urea-methanal, named for its common synthesis pathway and overall structure, is a

non-transparent thermosetting resin or polymer. It is produced from urea and formaldehyde. These resins are used in adhesives, plywood, particleboard, medium-density fibreboard, and moulded objects

-Petroleum based waxes are naturally hydrophobic and thus offer a cost effective

-Petroleum based waxes are naturally hydrophobic and thus offer a cost effective

way to impart moisture barrier properties in MDF, and other materials. Apart from providing moisture barriers, petroleum based wax products can provide dimensional integrity while facilitating better resin distribution in the boards.

9. Raw Materials For Laminate

-Laminates are generally made of paper that is treated with chemical resins to enhance its strength and stiffness. The main materials used when manufacturing all types of laminates, including kitchen laminates, are:

-Laminates are generally made of paper that is treated with chemical resins to enhance its strength and stiffness. The main materials used when manufacturing all types of laminates, including kitchen laminates, are:

Brown paper (also known as Kraft paper)

Phenolic resins (made from phenol)

Decorative Printed Paper

Melamine resin

Tissue paper (the topmost overlay of the laminated sheet)

Phenolic resins (made from phenol)

Decorative Printed Paper

Melamine resin

Tissue paper (the topmost overlay of the laminated sheet)

10. Manufacturing Plants

-Rushil Decor has a total of 5 manufacturing units. 3 in Gujarat for laminates having a total capacity of 3.5 Mn sheets per annum. And 1 in karnataka for MDF with a capacity of 90,000 cubic metre per annum. And another manufacturing facility for MDF has

-Rushil Decor has a total of 5 manufacturing units. 3 in Gujarat for laminates having a total capacity of 3.5 Mn sheets per annum. And 1 in karnataka for MDF with a capacity of 90,000 cubic metre per annum. And another manufacturing facility for MDF has

commenced its operations from March 2021 at Visakhapatnam, Andhra Pradesh. Having installed capacity of 800 cubic metres per day or 2,40,000 cubic metres per annum.

-Rushil decor also manufactures PVC sheets with an annual capacity of 12,480 CBM in existing units in Karnataka.

-Rushil decor also manufactures PVC sheets with an annual capacity of 12,480 CBM in existing units in Karnataka.

11. Distribution

-Rushil decor has different distribution channels for laminates and MDF.

-For laminates Rushil decor has 80+ distributors and 1600+ Retailers.

-The sales through the distribution channel for MDF, which is dealers and retailers, is about 80% of the volume and

-Rushil decor has different distribution channels for laminates and MDF.

-For laminates Rushil decor has 80+ distributors and 1600+ Retailers.

-The sales through the distribution channel for MDF, which is dealers and retailers, is about 80% of the volume and

combinations of the entire product range. Signature showrooms/display centres –’Vir laminates’ as well as ‘Vir Boards’ range of products all under one roof. As of March 2022, the Company has 150+ showrooms.

13. Company’s Key Focus Area

-Focusing on increasing the distributors and retailers to increase product reach.

-Developing more value-added products.

-Focusing on increasing the distributors and retailers to increase product reach.

-Developing more value-added products.

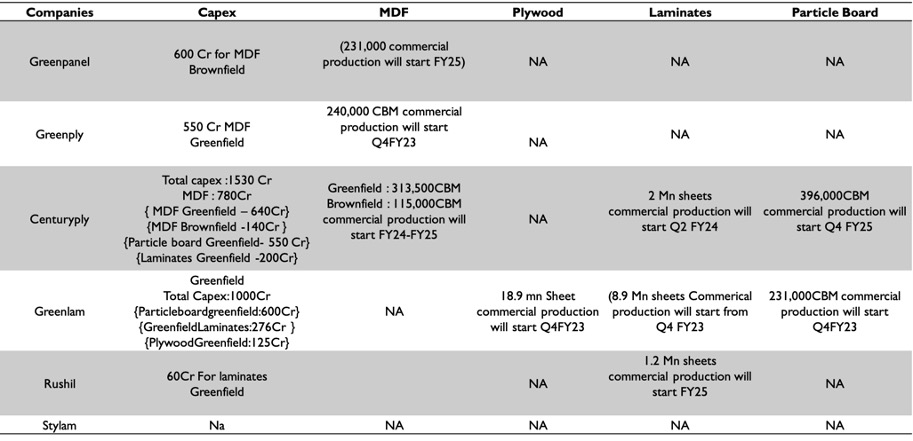

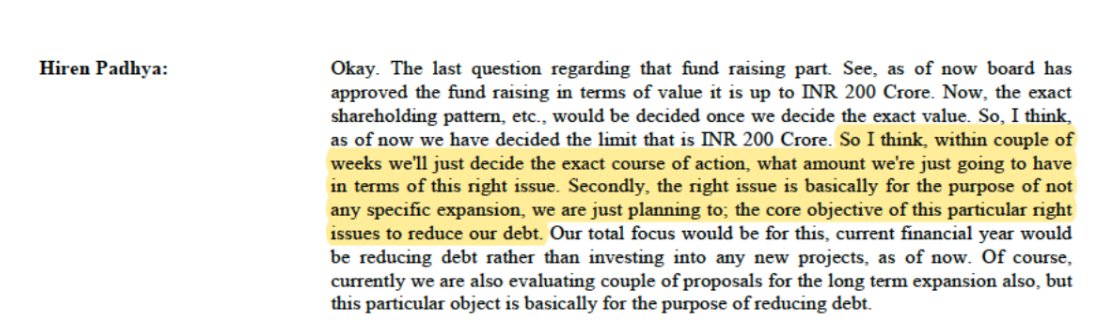

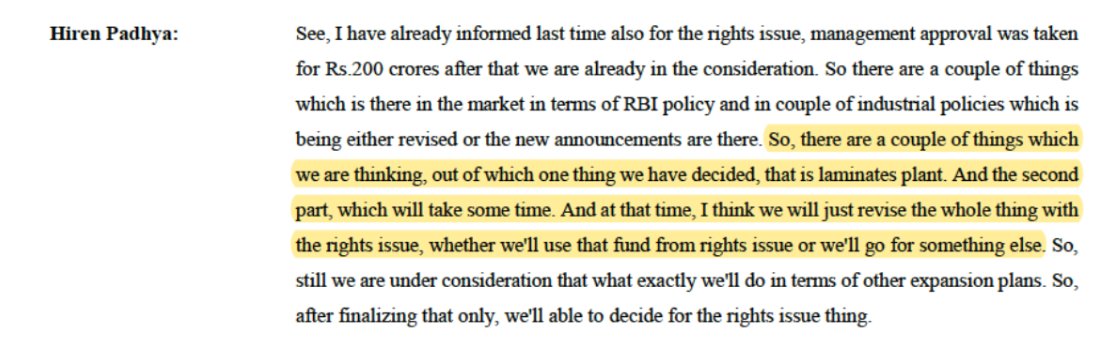

14. Future Capex

-Rushil Decor has announced greenfield expansion at a Capex of INR 60 crores in Laminates, which will add an additional manufacturing capacity of 1.2 Mn sheets per annum, raised through the combination of internal accruals and debt. And commercial production of

-Rushil Decor has announced greenfield expansion at a Capex of INR 60 crores in Laminates, which will add an additional manufacturing capacity of 1.2 Mn sheets per annum, raised through the combination of internal accruals and debt. And commercial production of

these manufacturing plant would start from FY25.

-Potential revenue from the capex would be around 100 crores plus as guidance given by the management.

-Potential revenue from the capex would be around 100 crores plus as guidance given by the management.

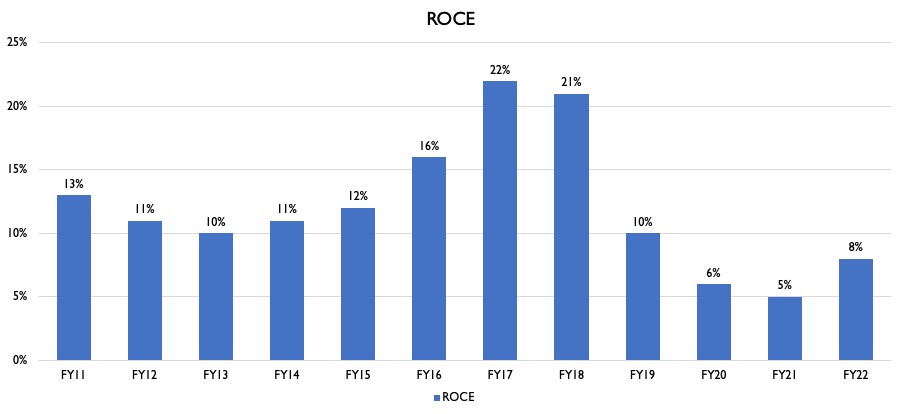

15. Financials

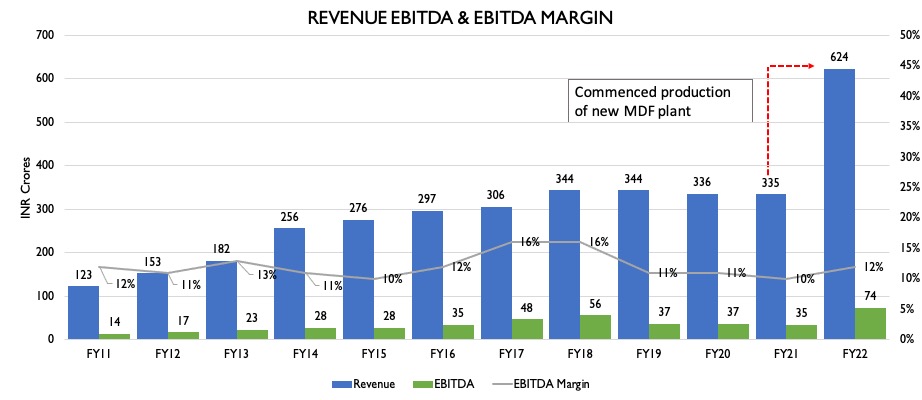

-Company’s revenue has increased from INR 123 Cr to INR 624 Cr in the past 12 years . Company’s EBITDA has grown from INR 14 Cr to INR 74 Cr. But their EBITDA margin is fluctuating because of historical events like higher imports in India of MDF in FY17, FY18,

-Company’s revenue has increased from INR 123 Cr to INR 624 Cr in the past 12 years . Company’s EBITDA has grown from INR 14 Cr to INR 74 Cr. But their EBITDA margin is fluctuating because of historical events like higher imports in India of MDF in FY17, FY18,

greenfield expansion at a Capex of INR 60 crores in Laminates, which will add an additional manufacturing capacity of 1.2 Mn sheets per annum

This will lead to an increase in the laminate volumes after the company starts commercial production

This will lead to an increase in the laminate volumes after the company starts commercial production

production of a new manufacturing unit with a capacity of 800 cubic metre MDF in Andhra Pradesh and the capex is around INR400 crores the management also gave guidance about potential revenue from capex which would be around INR 500 crores.

Loading suggestions...