Topics covered:

Company overview

Industry overview

Products

Business verticals

Management

Revenue Mix

Raw Materials

Value Chain

Manufacturing Plants

Company’s Key Focus Area

Capex

Financials.

Company overview

Industry overview

Products

Business verticals

Management

Revenue Mix

Raw Materials

Value Chain

Manufacturing Plants

Company’s Key Focus Area

Capex

Financials.

1) Company overview:

-Gravita India Ltd was established in 1990, with its first recycling plant at Jaipur, Rajasthan in 1994.The company is involved in the manufacturing of Lead through recycling Lead Acid batteries.The company has diversified into Aluminum and Plastic recycling,

-Gravita India Ltd was established in 1990, with its first recycling plant at Jaipur, Rajasthan in 1994.The company is involved in the manufacturing of Lead through recycling Lead Acid batteries.The company has diversified into Aluminum and Plastic recycling,

Further, they plan to diversify into Rubber, Steel, Copper and Paper.

- Gravita operates recycling facilities throughout North America and Africa. Up to calendar year 2028–2029, African businesses are free from paying any taxes.

- Gravita operates recycling facilities throughout North America and Africa. Up to calendar year 2028–2029, African businesses are free from paying any taxes.

Because Mozambique, Senegal, and Tanzania are classified as Least Developed Countries, 80-85% of the remelted lead produced there and imported into India is tax-free (other nations have a 5% tax).

-Ghana has Free Trade Agreements with Europe where it sells most of the produced refined lead and alloys.

-Gravita has 27 procurement yards and over 1,400 touchpoints. It ships recycled items to over 60 nations in North America, Europe, and the Middle East.

-Gravita has 27 procurement yards and over 1,400 touchpoints. It ships recycled items to over 60 nations in North America, Europe, and the Middle East.

It has 200+ customers in 18 states and has a pan-India footprint.

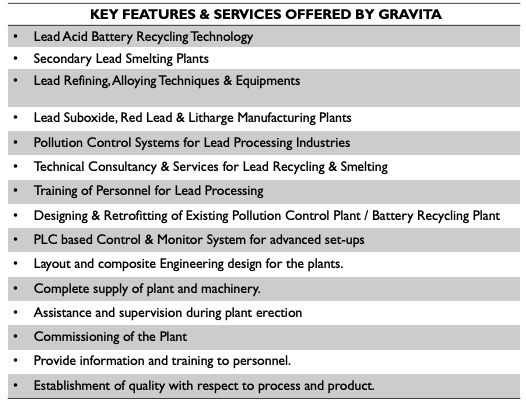

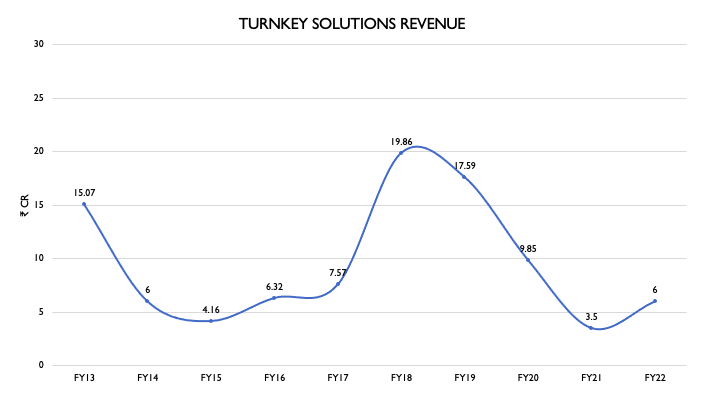

-Gravita also offers turnkey solutions (which includes engineering and machineries) such as Lead Rotary Furnace, Lead Refined Pots, Alloying Furnace, Pollution & Fugitive Emission Control Equipment,

-Gravita also offers turnkey solutions (which includes engineering and machineries) such as Lead Rotary Furnace, Lead Refined Pots, Alloying Furnace, Pollution & Fugitive Emission Control Equipment,

Battery Cutting Machine & Battery Crushing etc.

2) Industry overview: Lead is still mainly used for car batteries, pigments, ammunition, cable sheathing, weights for lifting, weight belts for diving, lead crystal glass & radiation protection.

2) Industry overview: Lead is still mainly used for car batteries, pigments, ammunition, cable sheathing, weights for lifting, weight belts for diving, lead crystal glass & radiation protection.

It is also used to store corrosive liquids.

The global market for lead-acid batteries is estimated in the range of US$38-42 billion, of which 66% is from automotive demand and the rest 29% industrial demand.

The global market for lead-acid batteries is estimated in the range of US$38-42 billion, of which 66% is from automotive demand and the rest 29% industrial demand.

In India, the lead-acid batteries market size is about ₹36,500 Cr. Some of the major players in the Indian market are Amara Raja, Exide, HBL, Luminous.

Unlike other battery technologies, about 99% of a lead-acid battery can be recycled in a green and safe manner.

Unlike other battery technologies, about 99% of a lead-acid battery can be recycled in a green and safe manner.

A- Lead:

Lead is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny grey with a hint of blue.

Lead is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny grey with a hint of blue.

An alloy is a blend of different metallic elements that are created to improve the strength and durability of the material. An aluminium alloy consists of main metal in the mix and combined with other elements, such as silicon, tin, manganese, or copper. With aluminium alloy,

C- Plastic:

Gravita's plastic business produces and sells recycled polypropylene granules and pet bottle flakes. Plastic scrap is used to make these plastic raw materials and plastic granules.

Gravita's plastic business produces and sells recycled polypropylene granules and pet bottle flakes. Plastic scrap is used to make these plastic raw materials and plastic granules.

4) Business Verticals:

Gravita India Ltd has three business verticals. Manufacturing Business, International Trade Business and Turnkey Solutions.

Gravita India Ltd has three business verticals. Manufacturing Business, International Trade Business and Turnkey Solutions.

A- Manufacturing Business

They carry out smelting of Lead Ore / Lead Concentrate / Lead Battery Scrap and Aluminium scrap to produce recycled Lead Metal and Aluminium Ingots. Through plastic waste they also manufacture recycled polypropylene granules and pet bottle flakes.

They carry out smelting of Lead Ore / Lead Concentrate / Lead Battery Scrap and Aluminium scrap to produce recycled Lead Metal and Aluminium Ingots. Through plastic waste they also manufacture recycled polypropylene granules and pet bottle flakes.

International Trade Business

They do export and import business in non-ferrous metals such lead metal, lead products, lead sheet, pure lead, lead alloys, lead battery waste, lead blocks, lead ore, and aluminium scrap across the world.

They do export and import business in non-ferrous metals such lead metal, lead products, lead sheet, pure lead, lead alloys, lead battery waste, lead blocks, lead ore, and aluminium scrap across the world.

MR RAJAT AGARWAL

MANAGING DIRECTOR:

He graduated from Malla Reddy Engineering College with a degree in mechanical engineering. He serves as the organisations managing director. His background in manufacturing spans more than 24 years.

MANAGING DIRECTOR:

He graduated from Malla Reddy Engineering College with a degree in mechanical engineering. He serves as the organisations managing director. His background in manufacturing spans more than 24 years.

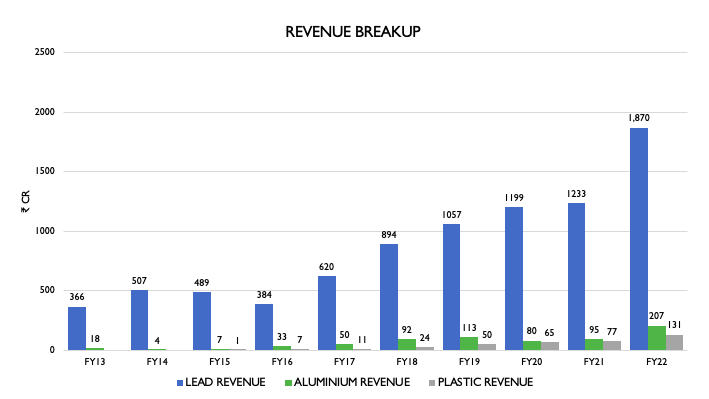

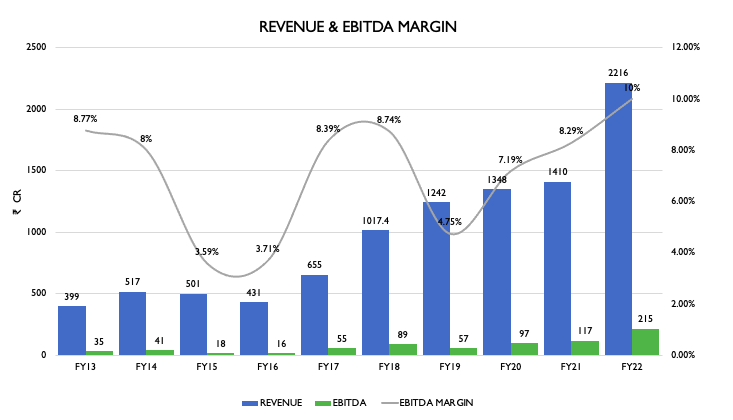

Gravita India Ltd is mainly in recycling of lead, aluminum and plastic and the company gets the majority of its revenue from lead recycling business. Earlier, from FY13 to FY16, we can see that their revenue was volatile.

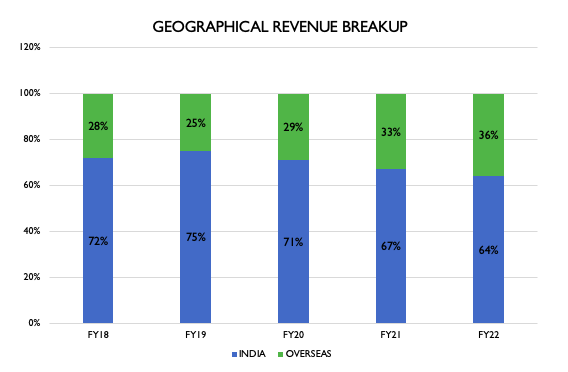

In this chart, we can see that revenue from India was 72% in FY18, while revenue from Overseas Business was 28%. Following that, the company expanded its operations and capacities in foreign markets. As a result,

there is an increase in income contribution from overseas in FY22 to around 36%. This has a positive influence on the firm since overseas business has a greater margin than domestic business due to the low cost of lead, aluminum, and plastic waste.

Gravita India uses raw materials like used lead acid batteries and Cable waste for manufacturing of recycled products. They also needed smelting additives like coal, Soda ash, cast iron, furnace oil and refining additives like caustic soda, sodium nitrate and sulphur powder.

They have increased their raw material sourcing majorly from domestic for the domestic business. In FY14 their raw material procurement from domestic was around 14% and in FY22 it was 54%.

And for international business they sourced raw materials internationally which is required for manufacturing and recycling.

Gravita India uses different tactics for acquiring raw materials from both domestic and foreign markets.

In terms of their domestic business, they get battery scrap from battery manufacturers and then recycle the battery trash into items like plastic, recycled lead, red oxide,

In terms of their domestic business, they get battery scrap from battery manufacturers and then recycle the battery trash into items like plastic, recycled lead, red oxide,

and lead oxide, which are then supplied to battery manufacturers. This is a critical component of the domestic lead industry.

The firm receives a supply of scrap that is utilised to make finished lead. Because net working capital in this sector is nearly nil,

The firm receives a supply of scrap that is utilised to make finished lead. Because net working capital in this sector is nearly nil,

As we know in FY22, the company procured nearly 54% of the raw material domestically and the rest they imported from America, Africa, and Europe for the domestic and international business.

They have manufacturing facilities in America and Africa, the material which they source internationally are consumed by their international manufacturing plants to make finished goods which can then be sent to the various countries.

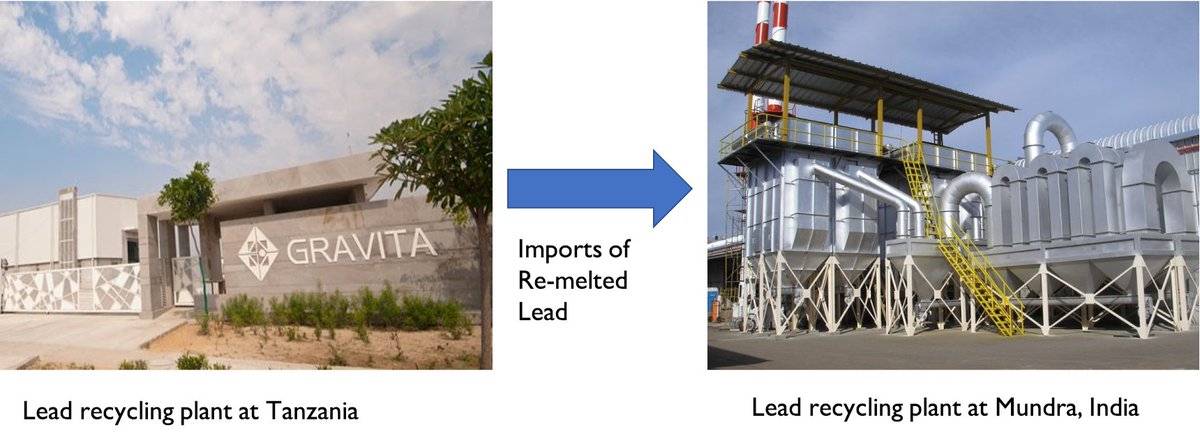

Also their plants in Mozambique and Tanzania produced re-melted lead, of which 80-85% is transported to India and then sold in the domestic market. They use this tactic because domestic scrap is costlier than imported scrap. Africa is included in least developed countries.

Hence, there is zero duty.

9) Manufacturing Plants

Gravita India Limited has 13 manufacturing plants in India and abroad.

There are six manufacturing plants in India, Mundra (Gujarat), Chittoor (Andhra Pradesh),Jaipur (Rajasthan), Jaipur SEZ (Rajasthan), Gandhidham (Gujarat),

9) Manufacturing Plants

Gravita India Limited has 13 manufacturing plants in India and abroad.

There are six manufacturing plants in India, Mundra (Gujarat), Chittoor (Andhra Pradesh),Jaipur (Rajasthan), Jaipur SEZ (Rajasthan), Gandhidham (Gujarat),

and Kathau (Jammu & Kashmir).

They have one manufacturing factory in Mirigama (Sri Lanka).

Gravita has five manufacturing plants in Africa: Ghana (Accra), Senegal (Dakar), Mozambique (Maputo), Tanzania (Dar-es-Salam), and Togo (Lome).

They have one manufacturing factory in Mirigama (Sri Lanka).

Gravita has five manufacturing plants in Africa: Ghana (Accra), Senegal (Dakar), Mozambique (Maputo), Tanzania (Dar-es-Salam), and Togo (Lome).

In addition, they operate one manufacturing factory in Nicaragua (North America).

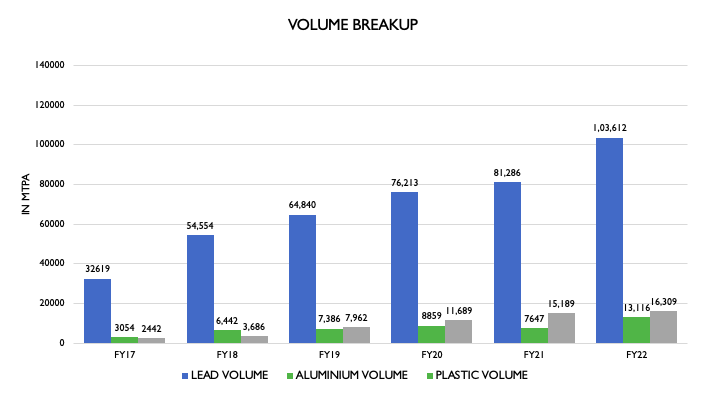

They have a total lead recycling production capacity of 173,119 MTPA per year. In aluminium they have a manufacturing capacity of 30,000 MTPA while plastic they have a capacity of 24,600 MTPA.

They have a total lead recycling production capacity of 173,119 MTPA per year. In aluminium they have a manufacturing capacity of 30,000 MTPA while plastic they have a capacity of 24,600 MTPA.

10) Company’s Key Focus Area:

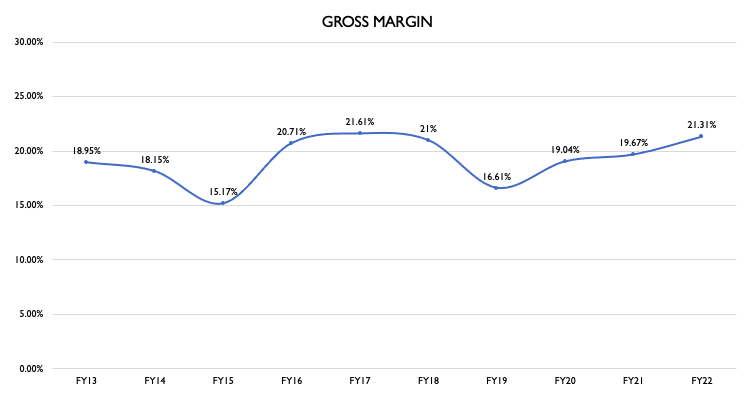

Gravita India Ltd is reducing dependency on single business which is lead recycling and entering into high margin business. As we can see, the firm is now recycling lead, aluminium, and plastic, with a total gross margin of roughly 21%.

Gravita India Ltd is reducing dependency on single business which is lead recycling and entering into high margin business. As we can see, the firm is now recycling lead, aluminium, and plastic, with a total gross margin of roughly 21%.

They are also expanding into new markets with high gross margins, such as rubber, which has a margin of 60-70%, and paper, which has a margin of 40%.

Gravita is also planning to enter in steel, paper and lithium ion, their goal is to increase non-lead business share to 25% from 15% currently.

Company is aiming to start lithium recycling by the end of the decade because scrap availability is very low as of now.

Company is aiming to start lithium recycling by the end of the decade because scrap availability is very low as of now.

They are also tying up with Israel and Europe for lithium recycling technology.

Gravita India is targeting to reduce their working capital days to 65 days till 2026. Because of that they are focusing on their Mundra plant.

Gravita India is targeting to reduce their working capital days to 65 days till 2026. Because of that they are focusing on their Mundra plant.

The Mundra plant helped the company to recycle lead near to the port itself which was going to the Jaipur facility earlier.

Their value added products are 43% in product mix and they are working to increase it to 50%.

Their value added products are 43% in product mix and they are working to increase it to 50%.

11) Capex:

Gravita India Ltd has a planned capex of ₹1300 Cr from 2022 to 2026. So out of ₹1300 Cr, ₹900 Cr will be funded from internal accruals and ₹300-₹400 Cr will be from debt or they may raise money from equity.

Gravita India Ltd has a planned capex of ₹1300 Cr from 2022 to 2026. So out of ₹1300 Cr, ₹900 Cr will be funded from internal accruals and ₹300-₹400 Cr will be from debt or they may raise money from equity.

Out of this ₹1300 Cr, ₹500 Cr is for expansion plans in the next two to three years, which can generate revenue of 8x to 9x out of this capex.

They will also spend ₹80 Cr year-on-year for their existing verticals for the next three years and around ₹200-250 Cr for the new verticals which include lithium-ion, copper, steel, paper over next 3 years. They will also need ₹800 Cr for their working capital requirement.

The payback period for this investment differs across local and international businesses. Hence, overseas, it would take less than two years. In the case of India, though, it should be completed in less than three years.

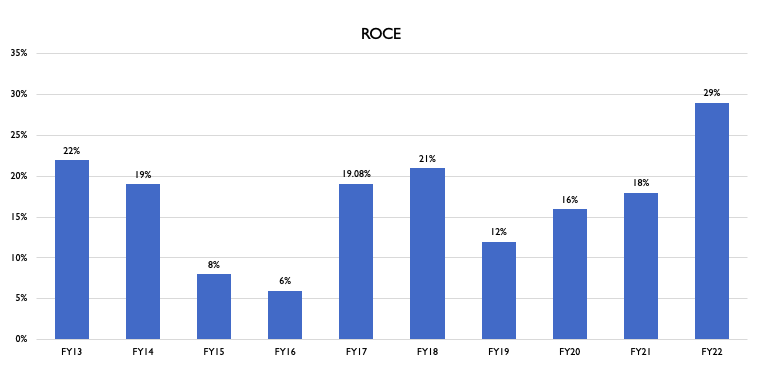

Gravita India Ltd commissioned manufacturing plants of Plastic in 2015 and Aluminum in 2016. In FY18, the company announced ₹150 Cr capex for 1-2 years which increased the capacity of their business segments by 50,000 tons.

We can see a consistent growth in their revenue and EBITDA due to that.

In July 2014, international lead prices were $2,200-2300 per ton. However, prices on the London Metal Exchange have decreased by more than 25%, to roughly $1,800 per ton.

In July 2014, international lead prices were $2,200-2300 per ton. However, prices on the London Metal Exchange have decreased by more than 25%, to roughly $1,800 per ton.

In the chart, we can see that prior to FY16, the company's gross margin was much lower. After that, Gravita India implemented a hedging mechanism for raw materials, which improved their margins.

Gravita India Ltd commissioned new production units for plastic (2015) and aluminum (2016), and they also began to increase the capacity of their current plants. This spending was paid mostly by internal accruals and borrowing.

Gravita India Ltd commissioned new manufacturing plants of Plastic ( 2015), Aluminum (2016). In FY18 the company announced ₹150 Cr capex for 1-2 years increasing the capacity of 50000 tons. So from FY17 onward we can see a decent growth in their ROCE.

In FY22, the ROCE is around 29% which is the highest ever for the company.

In FY22, their Mundra plant commenced production of lead recycling. They also shifted their existing Gandhi Dham facility to Mundra.

In FY22, their Mundra plant commenced production of lead recycling. They also shifted their existing Gandhi Dham facility to Mundra.

Loading suggestions...