Imagine running 10,000+ stores, serving 230M people a week, and never running out of stock.

Sounds impossible? Well, Walmart does it.

Here’s how it sets the gold standards in the supply chain… x.com

Sounds impossible? Well, Walmart does it.

Here’s how it sets the gold standards in the supply chain… x.com

It all starts with scale, Walmart serves 230M+ customers weekly.

- 10,616 global stores.

- 210 distribution centers, each moving 200+ trailers daily.

- 9,000 tractors covering 1B+ miles annually.

Even during the 2021 supply chain crisis, Walmart chartered their own ships. x.com

- 10,616 global stores.

- 210 distribution centers, each moving 200+ trailers daily.

- 9,000 tractors covering 1B+ miles annually.

Even during the 2021 supply chain crisis, Walmart chartered their own ships. x.com

But size alone isn’t enough to win, real magic lies in ‘data’.

Since 1983, they’ve used data, starting with barcodes to track products.

Today, RFID tags provide real-time inventory updates, cutting out-of-stock items by 16%.

Every scan shows what’s selling and what’s not. x.com

Since 1983, they’ve used data, starting with barcodes to track products.

Today, RFID tags provide real-time inventory updates, cutting out-of-stock items by 16%.

Every scan shows what’s selling and what’s not. x.com

Walmart’s story wouldn’t be complete without its suppliers.

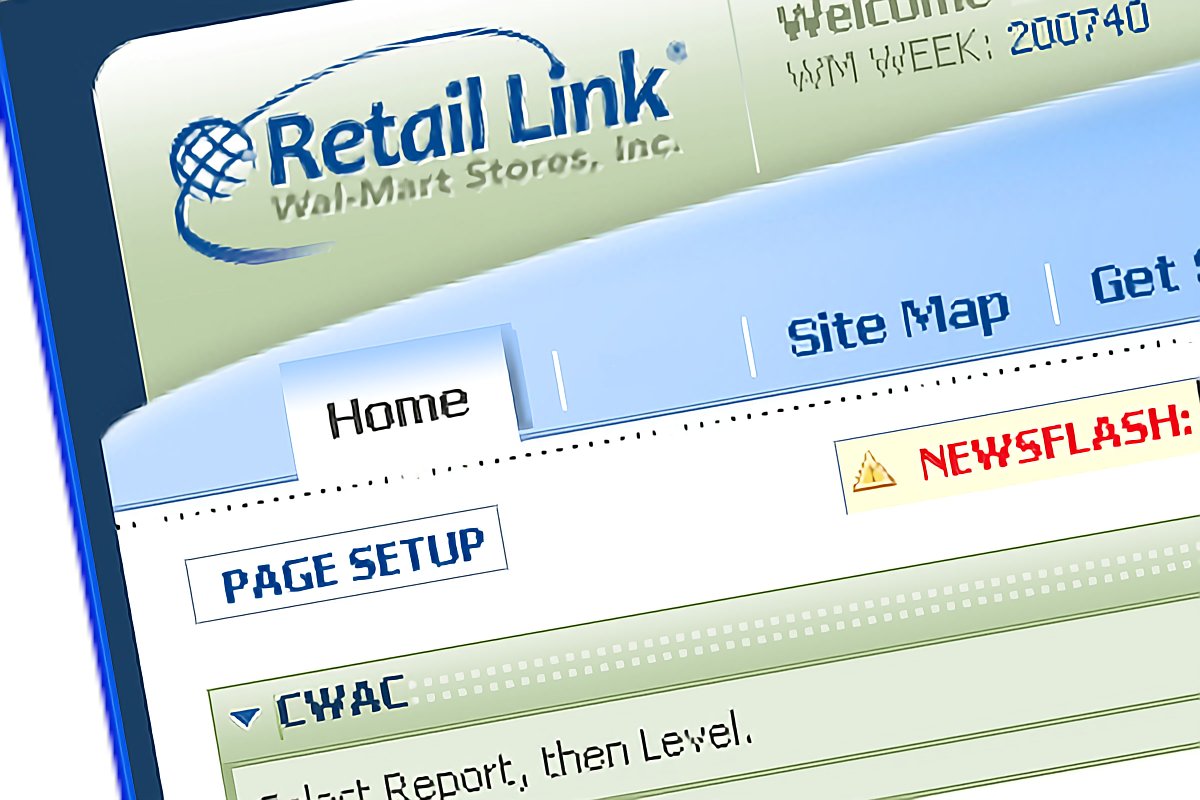

They use a tool; Retail Link®, to share real-time sales data with suppliers.

This helps suppliers predict demand, restock quickly, and avoid having too much or too little inventory.

It’s a win for everyone! x.com

They use a tool; Retail Link®, to share real-time sales data with suppliers.

This helps suppliers predict demand, restock quickly, and avoid having too much or too little inventory.

It’s a win for everyone! x.com

Let’s talk about how they move products so fast.

Walmart uses a system called cross-docking.

Products arrive at a distribution center, skip storage, and are loaded onto trucks the same day.

This means;

- Lower costs

- Quicker deliveries, and

- A smaller carbon footprint. x.com

Walmart uses a system called cross-docking.

Products arrive at a distribution center, skip storage, and are loaded onto trucks the same day.

This means;

- Lower costs

- Quicker deliveries, and

- A smaller carbon footprint. x.com

But the world is changing, and so are customer needs.

Walmart built Market Fulfillment Centers (MFCs) to connect online shopping with in-store pickups.

This means:

→ Faster delivery.

→ Easier store pickup.

The cool part is 90% of Americans live within 10 miles of a Walmart. x.com

Walmart built Market Fulfillment Centers (MFCs) to connect online shopping with in-store pickups.

This means:

→ Faster delivery.

→ Easier store pickup.

The cool part is 90% of Americans live within 10 miles of a Walmart. x.com

To meet the growing demand, Walmart invested $14B in supply chain tech in 2021.

Now robots sort and stack pallets.

Consolidation centers speed up operations and cut unnecessary shipments.

This isn’t just about saving money, it’s about building the future of logistics. x.com

Now robots sort and stack pallets.

Consolidation centers speed up operations and cut unnecessary shipments.

This isn’t just about saving money, it’s about building the future of logistics. x.com

And it’s not just about profits.

Walmart’s supply chain aligns with its sustainability goals:

Zero waste in the U.S. and Canada by 2025 and 100% renewable energy by 2035 (already at 36%).

They’re proving you can care for the planet and run a successful business. x.com

Walmart’s supply chain aligns with its sustainability goals:

Zero waste in the U.S. and Canada by 2025 and 100% renewable energy by 2035 (already at 36%).

They’re proving you can care for the planet and run a successful business. x.com

So, what can we learn from Walmart?

→ Share data for better collaboration.

→ Invest in tech for visibility.

→ Optimize relentlessly.

→ Align sustainability with business goals.

Their supply chain isn’t just logistics, it’s a blueprint for success. x.com

→ Share data for better collaboration.

→ Invest in tech for visibility.

→ Optimize relentlessly.

→ Align sustainability with business goals.

Their supply chain isn’t just logistics, it’s a blueprint for success. x.com

From how they use data to their automated processes and supplier collaborations, Walmart is always innovating.

Whether you’re in retail, shipping, or tech, there’s something to learn from their efficiency.

Whether you’re in retail, shipping, or tech, there’s something to learn from their efficiency.

This is just the tip of the iceberg.

Want to learn in detail how Walmart manages their supply chain effectively? Read our blog;

withvector.com

Want to learn in detail how Walmart manages their supply chain effectively? Read our blog;

withvector.com

At Vector, we have built a team of top technologists fundamentally rethinking how tools in logistics should work.

Follow for more latest insights in supply chain technology.

withvector.com

Follow for more latest insights in supply chain technology.

withvector.com

Loading suggestions...